Product Description

Automatic Return Force Car 1.5 Mandrel Diameter Mini Plastic

Pull Back Toy Car Gear Box Assembly Machine

This is a special fully automatic assembly machine for 1.5mm pull back

gear box toys. It adopts the latest technology to assembly the bottom cover,

small gearbox, gearbox, iron shaft and upper cover by fully automatic,which

saves labor and improves work efficiency.

The whole production line is from feeding, sorting, assembling, to optical fiber

detection of accessories, rejecting defective products, and finally to the discharge

of qualified finished products, realizing automatic production, stable and efficient,

high compatibility, and can effectively improve market competitiveness.

|

Machine Size |

L2666*W1960*H1952mm |

|

Output |

1700-1800pcs /hour |

|

Voltage |

220V |

|

Power |

10 KW |

|

Control Mode |

PLC Control |

|

Fuselage material |

Aluminium alloy |

|

Special requirement |

Different sizes are optional |

1. Automatically Delivering all the parts of iron wheel by vibration.

2. The Diameter of the iron wheel could be 26.32.34.

3. Adopts the latest technology to assembly all the parts by full automatically.

4.Detecting the defective products by optical fiber accurately and automatically.

5. Equipment with high production efficiency, and can have multiple machines for 1 operator,

effectively reducing manual operation costs.

1. Q: How is the after-sale service?

A: We provide 1 year guaranty and technical support lifetime. All parts of the machine can be replaced for free within 1 year if broken. (excluding error operation)

2. Q: Is it difficult to install the machine?

A: The work shop shore prepare full facility such as power and air compressor. For the first installation, our engineer will be sent to set machine and do the machine training as long as manual instruction. If the further problems come out, we can provide video instruction as well.

3. Q: What’s the machine lead time?

A: For the standard machines, we can delivery within 30 days. If it is customized by customer (OEM), the lead time is 35-55 days.

| Application: | Machinery, Toy |

|---|---|

| Function: | Speed Changing |

| Layout: | Cycloidal |

| Hardness: | Hardened Tooth Surface |

| Installation: | Vertical Type |

| Step: | Four-Step |

| Customization: |

Available

| Customized Request |

|---|

Developing a Mathematical Model of a Cyclone Gearbox

Compared to planetary gearboxes, cycloidal gearboxes are often seen as the ideal choice for a wide range of applications. They feature compact designs that are often low friction and high reduction ratios.

Low friction

Developing a mathematical model of a cycloidal gearbox was a challenge. The model was able to show the effects of a variety of geometric parameters on contact stresses. It was able to model stiction in all quadrants. It was able to show a clear correlation between the results from simulation and real-world measurements.

The model is based on a new approach that enables modeling stiction in all quadrants of a gearbox. It is also able to display non-zero current at standstill. Combined with a good simulation algorithm, the model can be used to improve the dynamic behaviour of a controlled system.

A cycloidal gearbox is a compact actuator used for industrial automation. This type of gearbox provides high gear ratios, low wear, and good torsional stiffness. In addition, it has good shock load capacity.

The model is based on cycloidal discs that engage with pins on a stationary ring gear. The resulting friction function occurs when the rotor begins to rotate. It also occurs when the rotor reverses its rotation. The model has two curves, one for motor and one for generator mode.

The trochoidal profile on the cycloidal disc’s periphery is required for proper mating of the rotating parts. In addition, the profile should be defined accurately. This will allow an even distribution of contact forces.

The model was used to compare the relative performance of a cycloidal gearbox with that of an involute gearbox. This comparison indicates that the cycloidal gearbox can withstand more load than an involute gearbox. It is also able to last longer. It is also able to produce high gear ratios in a small space.

The model used is able to capture the exact geometry of the parts. It can also allow a better analysis of stresses.

Compact

Unlike helical gearing, compact cycloidal gearboxes can provide higher reduction ratios. They are more compact and less weighty. In addition, they provide better positioning accuracy.

Cycloid drives provide high torque and load capacity. They are also very efficient and robust. They are ideal for applications with heavy loads or shock loads. They also feature low backlash and high torsional stiffness. Cycloid gearboxes are available in a variety of designs.

Cycloid discs are mounted on an eccentric input shaft, which drives them around a stationary ring gear. The ring gear consists of many pins, and the cycloidal disc moves one lobe for every rotation of the input shaft. The output shaft contains roller pins, which rotate around holes in the cycloidal disc.

Cycloid drives are ideally suited to heavy loads and shock loads. They have high torsional stiffness and high reduction ratios, making them very efficient. Cycloid gearboxes have low backlash and high torque and are very compact.

Cycloid gearboxes are used for a wide variety of applications, including marine propulsion systems, CNC machining centers, medical technology, and manipulation robots. They are especially useful in applications with critical positioning accuracy, such as surgical positioning systems. Cycloid gearboxes feature extremely low hysteresis loss and low backlash over extended periods of use.

Cycloid discs are usually designed with a reduced cycloid diameter to minimize unbalance forces at high speeds. Cycloid drives also feature minimal backlash, a high reduction ratio, and excellent positioning accuracy. Cycloid gearboxes also have a long service life, compared to other gear drives. Cycloid drives are highly robust, and offer higher reduction ratios than helical gear drives.

Cycloid gearboxes have a low cost and are easy to print. CZPT gearboxes are available in a wide range of sizes and can produce high torque on the output axis.

High reduction ratio

Among the types of gearboxes available, a high reduction ratio cycloidal gearbox is a popular choice in the automation field. This gearbox is used in applications requiring precise output and high efficiency.

Cycloid gears can provide high torque and transmit it well. They have low friction and a small backlash. They are widely used in robotic joints. However, they require special tools to manufacture. Some have even been 3D printed.

A cycloidal gearbox is typically a three-stage structure that includes an input hub, an output hub, and two cycloidal gears that rotate around each other. The input hub mounts movable pins and rollers, while the output hub mounts a stationary ring gear.

The input shaft is driven by an eccentric bearing. The disc is then pushed against the ring gear, which causes it to rotate around the bearing. As the disc rotates, the pins on the ring gear drive the pins on the output shaft.

The input shaft rotates a maximum of nine revolutions, while the output shaft rotates three revolutions. This means that the input shaft has to rotate over eleven million times before the output shaft is able to rotate. The output shaft also rotates in the opposite direction of the input shaft.

In a two-stage differential cycloidal speed reducer, the input shaft uses a crank shaft design. The crank shaft connects the first and second cycloidal gears and actuates them simultaneously.

The first stage is a cycloidal disc, which is a gear tooth profile. It has n=7 lobes on its circumference. Each lobe moves around a reference pitch circle of pins. The disc then advances in 360deg steps.

The second stage is a cycloidal disc, also known as a “grinder gear”. The teeth on the outer gear are fewer than the teeth on the inner gear. This allows the gear to be geardown based on the number of teeth.

Kinematics

Various scholars have studied the kinematics of cycloidal gearbox. They have developed various approaches to modify the tooth profile of cycloidal gears. Some of these approaches involve changing the shape of the cycloidal disc, and changing the grinding wheel center position.

This paper describes a new approach to cycloid gear profile modification. It is based on a mathematical model and incorporates several important parameters such as pressure angle, backlash, and root clearance. The study offers a new way for modification design of cycloid gears in precision reducers for robots.

The pressure angle of a tooth profile is an intersegment angle between the normal direction and the velocity direction at a meshing point. The pressure angle distribution is important for determining force transmission performance of gear teeth in meshing. The distribution trend can be obtained by calculating the equation (5).

The mathematical model for modification of the tooth profile can be obtained by establishing the relationship between the pressure angle distribution and the modification function. The dependent variable is the modification DL and the independent variable is the pressure angle a.

The position of the reference point A is a major consideration in the modification design. It ensures the force transmission performance of the meshing segment is optimal. It is determined by the smallest profile pressure angle. The position is also dependent on the type of gear that is being modified. It is also influenced by the tooth backlash.

The mathematical model governing the pressure angle distribution is developed with DL=f(a). It is a piecewise function that determines the pressure angle distribution of a tooth profile. It can also be expressed as DL=ph.

The pressure angle of a tooth is also an angle between the common normal direction at the meshing point and the rotation velocity direction of the cycloid gear.

Planetary gearboxes vs cycloidal gearboxes

Generally, there are two types of gearboxes that are used for motion control applications: cycloidal gearbox and planetary gearbox. Cycloid gearboxes are used for high-frequency motions, while planetary gearboxes are suitable for low-speed applications. Both are highly accurate and precise gearboxes that are capable of handling heavy loads at high cycle rates. But they have different advantages and disadvantages. So, engineers need to determine which type of gearbox is best suited for their application.

Cycloid gearboxes are commonly used in industrial automation. They provide excellent performance with ratios as low as 10:1. They offer a more compact design, higher torque density and greater overload protection. They also require less space and are less expensive than planetary gearboxes.

On the other hand, planetary gearboxes are lightweight and offer a higher torque density. They are also capable of handling higher ratios. They have a longer life span and are more precise and durable. They can be found in a variety of styles, including square-framed, round-framed and double-frame designs. They offer a wide range of torque and speed capabilities and are used for numerous applications.

Cycloid gearboxes can be manufactured with different types of cycloidal cams, including single or compound cycloidal cams. Cycloid cams are cylindrical elements that have cam followers that rotate in an eccentric fashion. The cam followers act like teeth on the internal gear. Cycloid cams are a simple concept, but they have numerous advantages. They have a low backlash over extended periods of time, allowing for more accurate positioning. They also have internal compressive stresses and an overlap factor between the rolling elements.

Planetary gearboxes are characterized by three basic force-transmitting elements: ring gear, sun gear, and planet gear. They are generally two-stage gearboxes. The sun gear is attached to the input shaft, which in turn is attached to the servomotor. The ring gear turns the sun gear and the planet gear turns the output shaft.

editor by CX 2023-11-07

in Maiduguri Nigeria sales price shop near me near me shop factory supplier 3V DC coreless mini plastic gear motor for intelligence manufacturer best Cost Custom Cheap wholesaler

If you are interested in any of our goods or would like to discuss a prospective order, remember to feel free of charge to make contact with us. Quality and credit are the bases that make a company alive. EPG has been productively licensed by ISO9002 Top quality Administration System, ISO9001 Top quality Management Method, API certificate, ISO/TS16949:2002 and ISO10012 measurement administration program. 3V dc coreless mini plastic EPT motor for intelligence

Principal Characteristics

one periodOEM solODM 6mm planetary EPTT additionally 6mm Coreless motor

two periodSmall size dc EPT motor with reduced pace and big torque

3 period6mm EPT motor provide 50g periodcm torque and far more reliabl

four periodSuitable to modest diameter comma reduced noise and massive torque software

5 periodReduction ratio colon136 comma700

| EPT colonTGPP06-D-136 | |

| Rated Voltage | 3VDC |

| No-load velocity rpm | 240rpm |

| No-load present | 60mA |

| Stall torque | 120g periodcm |

| Stall recent | period2A |

| EPT colonTGPP06-D-700 | |

| Rated Voltage | 3VDC |

| No-load velocity rpm | 47rpm |

| No-load recent | 60mA |

| Stall torque | 500g periodcm |

| Stall recent | period2A |

Item Application

| Other Applications colon | |

| Organization EPTTs colon | ATM comma Copiers and Scanners comma Currency EPT comma Level of Sale comma Printers comma Vending EPTTs period |

| Foodstuff and EPTTrage colon | EPTTrage Dispensing comma Hand Blenders comma Blenders comma Mixers comma Espresso EPTTs comma Food Processors comma Juicers comma Fryers comma Ice Makers comma Soy Bean Milk Makers period of time |

| Residence EPTTrtainment and Gaming colon | Gaming EPTTs comma Online video Game titles comma EPTal Disk Drives comma RC and EPTT Toys period of time |

| Residence EPTnologies colon | Home EPT comma Air Purifiers and Dehumidifiers comma Range Hoods comma Washers and Dryers comma Fridges comma Dishwashers comma EPTr Care comma Whirlpool and Spa comma Showers comma EPT Metering comma Coffee EPTTs interval |

| Garden and XiHu (West EPT) Dis.Hu (West EPT) Dis.den colon | Lawn Mowers comma Snow Blowers comma Trimmers comma Leaf Blowers period of time |

| Personalized Treatment colon | Hair Reducing comma Hair Treatment comma Massagers period |

| EPTT Resources colon | Drills and Motorists comma Sanders comma Grinders comma PoEPTTrs comma Saws period of time |

| Digital camera and EPTal colon | Video comma Cameras comma Projectors period |

EPTT amp Supply

EPTT colon one carton EPTT comma a hundred parts for each box time period

EPT time colon

DHL colon three-five doing work daEPTT semi

UPS colon five-seven working times semi

TNT colon five-seven functioning times semi

FedEx colon 7-nine functioning times semi

EMS colon 12-fifteen functioning days semi

EPTT Post colon Relies upon on ship to which country semi

Sea colon Depends on ship to which country

Our organization

TT EPT lparHK rpar EPTT Co time period comma Ltd has been EPTTizing in micro motors comma EPT motors and their respective elements since 2000 period of time

Our merchandise are widely used in EPTTrtainment systems comma vehicles comma home and EPTT EPTs and resources and several other people period Our merchandise are reliable and EPTT-long lasting comma and backed by many years of knowledge period We export 98 percnt of our output globally period of time

By EPTaging our tough-won reputation for honesty comma dependability and top quality comma TT EPT aims to keep on as a pioneer in the product sales overEPTT by in search of EPTT partners interval If your business is an stop-person of micro-motors comma a distributor or an agent comma you should contact us time period We appear EPTT to getting capable to operate together with you in the in close proximity to EPT interval

FAQ

Q colon How to buy quest

A colon deliver us inquiry rightEPT EPT our quotation rightEPT negotiate particulars rightEPT affirm the sample rightEPT indication deal soldeposit rightEPT mass manufacturing rightEPT cargo completely ready rightEPT harmony soldelivery rightEPT even more cooperation period

Q colon How about Sample get quest

A colon Sample is available for you interval make sure you get in touch with us for specifics period of time Our internet site colonwww periodttmotor periodcom

Q colon Which delivery way is avaliable quest

A colon DHL comma UPS comma FedEx comma TNT comma EMS comma EPTT Post commaSea are accessible periodThe other shipping waEPTTare also offered comma you should get in touch with us if you need ship by the other shipping way time period

Q colon How EPTT is the deliver quest

A colon Devliver time depends on the quantity you get time period normally it will take 15-twenty five working times time period

Q colon My package deal has lacking products interval What can I do quest

A colon Please get in touch with our support crew and we will confirm your orEPTTwith the bundle contents periodWe apologize for any inconveniences time period

Q colon How to validate the payment quest

A colon We settle for payment by T solT comma PayPal comma the other payment waEPTTalso could be accepted commaPlease get in touch with us ahead of you pay by the other payment methods time period Also thirty-fifty percnt deposit is obtainable comma the harmony funds need to be compensated ahead of transport period of time

China manufacturer & factory supplier for factory in Mogadishu Somalia manufacturer for High quality small metal gear bevel gears plastic pp With high quality best price & service

We help a nationwide foundation of Industrial Distributors, and Original Equipment Producers as well as Agricultural Equipment Manufacturers and Wholesalers. Positioned in Memphis, TN we are at the middle of a single of the premier distribution hubs in the region and with our comprehensive stock levels and unrestricted transport choices, we are able to supply our customers with accurate on-time deliveries. It has established secure cooperation with a lot of well recognized universities and institutes in china this sort of as, Zhejiang University, Jilin College, Technological committee of nationwide chain push regular, Institute of countrywide chain push, Zhejiang application engineering material institute, Huhan content security institute and it cooperated to identified China First Auto chain institute with Nationwide chain push institute.

Overview

Fast Specifics

- Applicable Industries:

-

Production Plant

- Item Keywords:

-

little metal gear,small bevel gears,plastic pp equipment

EPG Equipment is found in XiHu Spot HangZhou Zhejiang ,China. It is 30km from our manufacturing facility to HangZhou worldwide airport.

Offer Potential

- Offer Capability:

- 5000 Piece/Parts for each Month

Packaging & Delivery

- Packaging Specifics

- Neutral paper packaging, wood boxes for outer box or according to customer’s demand.

- Port

- Shanghai Port / Ningbo Port

Online Customization

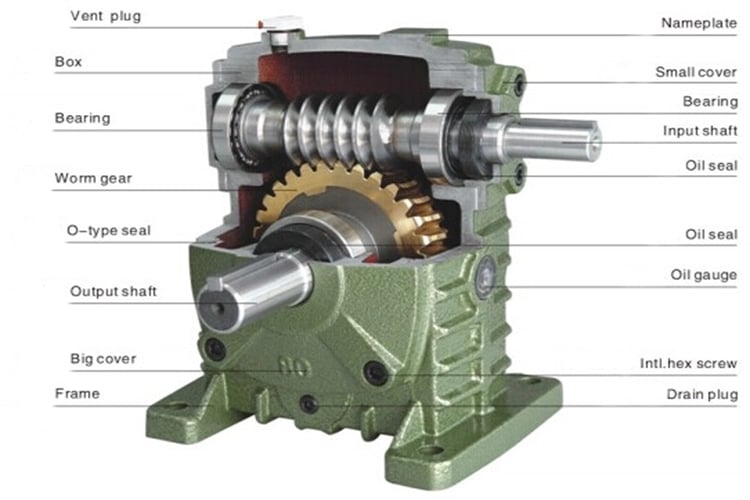

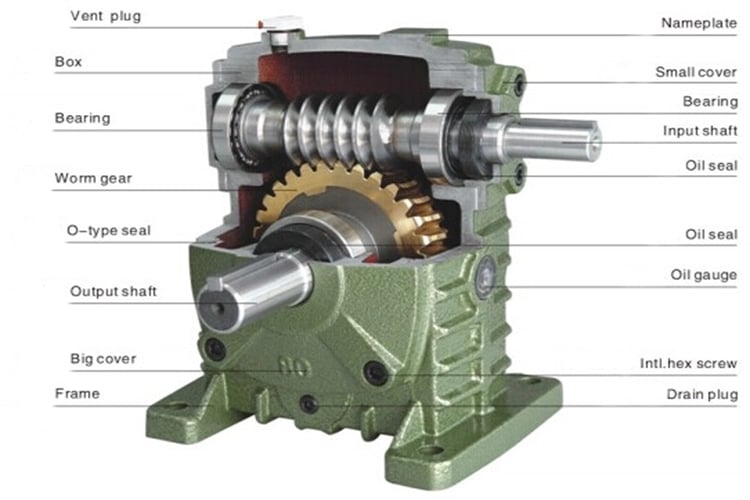

EPG ’s challenge is to grow to be a reference in the discipline of sustained advancements applied to gearboxes and gearmotors, basing our development and advancement on our Top quality-Item-Services philosophy. Worm Gearbox Worm Gearbox, Worm Speed Reducer, Industrial Proper Angle Worm Gearboxes Worm Pace reducer

We At any time-Electrical power Team with 4 branches more than 1200 personnel is one of the greatest transmission elements and machining products companies in China

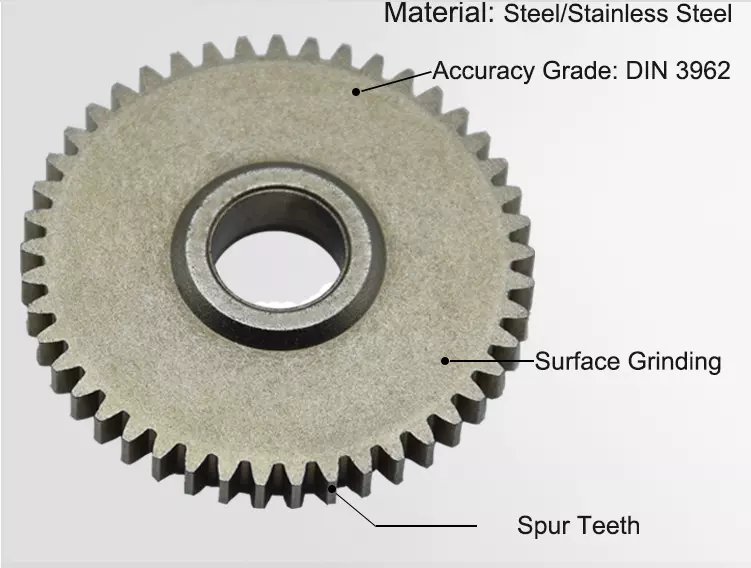

Solution Description

Item Description:

We specialised in manufacturing automobile gears , motorbike gears, gearbox, specific vehicle (energy takeoff, snowmobiles, engineering cars) gears, generator components, stainless steel ice crusher etc.

|

Content |

1020,1045,20CrMnTi, etc. |

|

Machining Method |

Gear Hobbing , Equipment Shaping, Equipment Shaving, Gear Grinding |

|

Modules |

one., 1.25, 1.5, 1.75, 2., 2.25, 2.5….8. etc. |

|

Heat Remedy |

Carburizing & Quenching, Carbonitriding |

|

Normal |

DIN, ISO/GB, AGMA, JIS,ISO/TS16949:2009 |

PTO shaft connectors on tractors are not standardized which can lead to difficulties when connecting the PTO shaft. For case in point, some more mature tractor versions have the relationship flange nearer to the tractor itself generating it challenging to hook up and direct to a possible safety hazard.

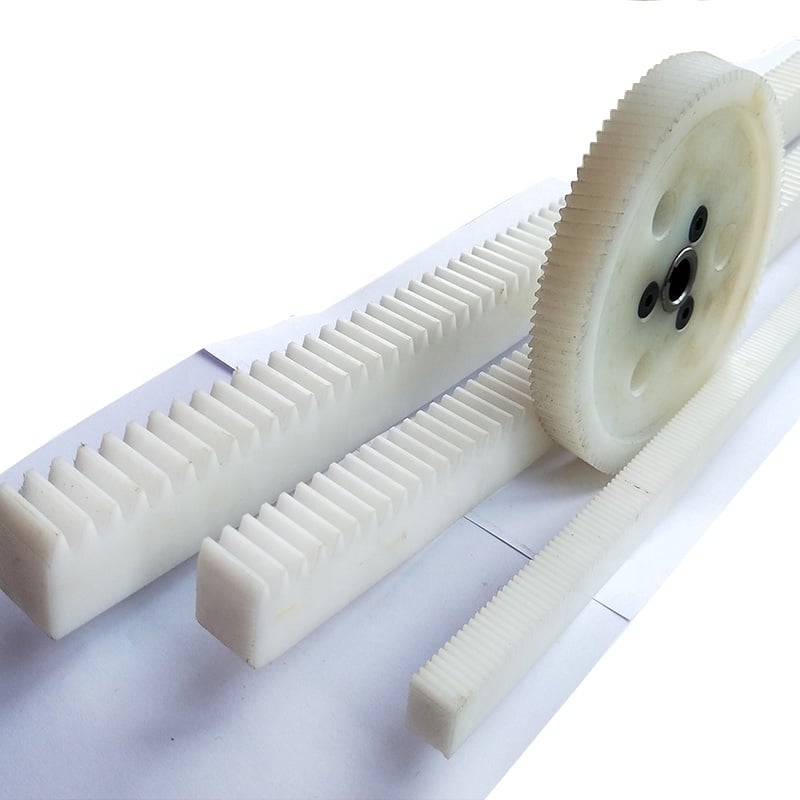

Best China manufacturer & factory China manufacturer Plastic gear Module 1.5 manufacturing With high quality best price

We are aiming to meet the demands of the clients around the world.. a specialized supplier of a full range of chains, sprockets, gears, gear racks, V-belts, couplings and reducers, pto shaft, agricultural gearboxes….

Overview

Quick Details

-

SFI M100 PTO AdapterAs a precautionary measure, it is a good idea to purchase a PTO adapter to ensure compatibility with your particular tractor model.

- Applicable Industries:

-

Building Material Shops, Manufacturing Plant, Machinery Repair Shops, Food & Beverage Factory, farms, Construction works , Energy & Mining, agricultural machiner

- Product Name:

-

Plastic gear Module 1.5 manufacturing

- Mod.(Standard):

-

M1,M1.5,M2,M3,M4,M5,M6

- Nonstandard:

-

EPG is a company specialized in the manufacture of the speed reducers for industry in general. From this idea, Mr. Alan began his activity in 1997. In small installations, the first gears and carcasses were manufactured and mechanized, while mounting the first reducers from mark EPG. With becoming to the years, we have passed from a small workshop of almost 150 meters to the new installation that occupy a surface of 5.800 meters.

According to customers’ drawing

- Processing:

-

CNC Machining

- Surface:

-

No burrs, No scratch

- Shape:

-

SPUR

“EPG” brand rotocultivator ploughshares in T.S. total lines produced in our factory have been tested and appraised by the Ministry of Agriculture and have obtained the license of popularizing farm machinery promulgated by the Ministry of Agriculture of the People’s Republic of China.

Supply Ability

- Supply Ability:

- 7000 Piece/Pieces per Month

Packaging & Delivery

- Packaging Details

- Carton box,Wooden packing or according to customers’ requirements

- Port

- Tianjin

-

Lead Time

: -

Quantity(Bags) 1 – 500 >500 Est. Time(days) 12 To be negotiated

Online Customization

EPG – one of the biggest transmisison suppliers in China. Every process, every section, every function in EPG is demanded to be done one step following another, carefully and cautiously, from material selection, reformation to manufacturing accessories, from components heat treatment to automatic assembly, from quality control to product inspection and testing and from order dealing to after sales service.”We are always serving our customers with our best products.” EPG will always adhere to it enterprise spirit of being practical, innovative, efficient and excellent to make the top international transmission drive.

Product Description

Plastic gear Module 1.5 manufacturing

FUTURE SUCCESS BELONGS TO QUALITY LEADER!

BUILDING BRAND ON QUALITY!

|

Product name |

Plastic gear Module 1.5 manufacturing |

||

|

Item |

M0.5,M1,M1.5,M1.7,M2,M2.5,M3,M4,M5,M6 and so on |

||

|

Standard |

European or American standard |

||

|

Material |

carbon steel such as C45, 20CrMnTi, 40Cr, 42CrMo or stainless steel or copper, brass or nylon etc. |

||

|

Heat Treatment |

Hardening and Tempering, High Frequency Quenching, Carburizing Quenching and so on |

||

|

OEM service |

make based on your special sample or drawing and meet your need for high precision on teeth of gear |

||

HRSY Spur Gear Catalogue

Please choose your module number, please contact us to get more catalogue.

Our Company

HangZhou EGP Electrical Equipment Co.,Ltd was founded in HangZhou in 1997 and is a professional manufacturer and exporter that is concerned with the design, development and production.With detailed requirments, we can also develop your special designed product. Our product range includes all kinds of Timing pulley,helical gear, spur gear, bevel gear, gear rack, worm gear, sprockets,Motorcycle sprockets and chains

· Our Principle: “Credibility Supremacy, and Customer First”

· Our Promise: “High quality products, and Excellent Service”

· Our Value: “Being Honesty, Doing the Best, and Long-lasting Development”

· Our Aim: “Develop to be a leader in the power transmission parts industry in the world”

Packing & Delivery

———————————————— packaging ————————————–

—————————————– SHIPMENT ————————————–

Whether you have your own freight-forward or you would like us to arrange the shipment.

Whether you require delivery FOB to a port in China Or CIF to a port near you, we are happy to quote and supply whichever may you choose. Please feel free to let me know your option.

FAQ

Q1: Are you manufacturer or Trade Company?

A: Both we are. We have been in conveying equipment for 18 years and it will be longer. Now we have

developed into a technical team of 10 experienced engineers.

Q2: What’s the warranty of your products?

A: Usually we guarantee one year after delivery date, but depending on the specified product.

Q3: What is your payment?

A: Our usual payment is T/T, L/C. You can choose the best one according to your situation. 30% in

advance as the deposit and the balance is paid before shipment.

Q4: What information should I let you know if I want to get a precise quotation?

A: Please send us your inquiry with our products model number or drawing by email or fax, we will offer

you our price list, offer sheet and order information within one working day.

Q5: Are you willing to provide the samples?

A: We can supply some free samples (total value under 10 US dollars) if you have a DHL, TNT, UPS or

FedEx account or other courier freight collectable account and agree to pay the courier freight.

·If the total value of samples is more than 10 US dollars, we’d like to ask you to pay for the samples and

courier freight; we will send the samples to you after receipt of your payment.

·If you don’t have courier account, you can send your courier to collect samples from our company, or

send us the samples charge together with the courier cost by T/T.

·The charge both sample and courier cost will be return you once the mass order placed.

Q6: Can you provide OEM service?

A: Of course, we can. Besides, we’ll provide our professional suggestion for you as to your practical

needs.

Q7: Do you inspect the finished products?

A: Yes, each step of production and finished products will be carried out inspection by QC departing

before shipping.

HRSY Main Products

Industrial Sprocket

Motorcycle Sprocket

Roller Chain

Spur Gear

Helical Gear

Bevel Gear

Plastic/POM/Nylon Gear

Small Pinion Gear

Worm Gear and shaft

Gear Rack

Timing Pulley

Taper Bushing

Chain Guides

Linear Rail and Block

Ball Screw

Contact Information