Product Description

Overview

Product Description

Wide Selection of Gearbox Products

The gearbox usually adopts a general design scheme, but in special cases, the design scheme of the gearbox can be changed according to the demands of the user, and it can be modified into an industry-specific gearbox. In the design scheme of the gearbox, the parallel shaft, vertical shaft, general box, and various parts can be changed

Advantages

- Absorption of very high torques and axial forces

- No need for separate thrust housing & bearing.

- Easy alignment (screw directly fits into the vore of gear box)

- Easy to assemble & dismantle.

- Very heavy duty spherical roller thrust bearing is provided.

- Power saving. (you may save up to 20 % power.)

- Less requirement of space.

- For bigger sizes water cooling is provided

- No maintenance required except periodic oil level checking.

- Higher productivity

Features

- Twin Screw Extruder Gearboxes offer the dual shaft counter rotating. The range is available for various center distances

- The gearboxes are available with co-rotating and counter rotating variants

- To work under heavy loading force, the high level dissipation and oil lubrication system are provided. The axial roller type swivel thrust with the thrust bearing coupled in tandem way support the axial thrust

- High torque and high speed output rate

Processing Characteristics of Screw Shaft:

1.Suitable suggestion on material to ensure components performance and extend lifetime of products.

2.Professional technical team can provide surveying and mapping support.

3.All components are finished by CNC machine.

4.Sophisticated quality management system ensure superior quality.

Basic Info.

| Warranty: 1 year | Weight (KG): 500 KG |

| Place of Origin: HangZhou, China |

Gearing Arrangement: helical |

| ratio: 8-20 |

Output Torque: 2*176 |

| standard: JB/T8853-2001 |

Certificate: CE |

| Heat treatment: High-frequency Hardening |

Efficiency: 94%~98%(depends on the transmission stage) |

| Customized support:OEM ODM | Input/output shaft material 40Cr |

| Package: Wooden case |

Mount position: Flange, hollow shaft, CHINAMFG shaft |

| After-sale:Online 24/7 Installation Xihu (West Lake) Dis. | advantage: excellent quality |

| Reduction radio: 3:1 |

Mount Position: Horizontal Foot Mounted Vertical |

| Input Speed: 1500 |

Output Speed: 500 |

Packaging & delivery

|

Packing: wooden case packing |

|

| Port: HangZhou Port |

Applications

X helical gear units for double-screw extruders with parallel drive shafts and the same direction of screw rotation are used mainly in the manufacture of granulates and the refining of raw plastics. Other areas of application include:

- Paint and lacquer industry

- Washing agent industry

- Foodstuff industry (e.g. bread, pasta)

- Animal-feed industry (dog, cat other animal food

Maintenance of the gearbox of the dual-screw extruder

1. The gear box of the dual-screw extruder should be well-ventilated, and the working environment temperature should be within the range of 5-35 °C.

2. Always check the oil quantity of the gear lubricating oil in the box to ensure that the transmission parts in the box are well lubricated.

3. Pay attention to check the bearing parts of the box frequently. The oil temperature of the oil tank of the transmission box should not exceed 70 ºC during operation.

4. The newly put into use gearbox needs to replace the lubricating oil after 250 hours of operation. The oil change time depends on the state of the oil. It is recommended to replace it after 4000-8000 hours of operation or once a year.

5. The gearbox of the dual-screw extruder needs to be regularly maintained and inspected once a year

Operating Process

1. The gear on the input shaft is driven by the motor and starts to rotate.

2. The rotating input gear meshes with other gears inside the gearbox, transmitting power.

3. Different-sized gears within the gearbox are combined to form a gear train. Through continuous meshing and rotation, the high-speed, low-torque power from the input shaft gradually converts into low-speed, high-torque output.

4. The output shaft is connected to the last gear and transfers the output torque to the load.

5. Gear reduction gearboxes typically include lubrication and cooling systems to ensure smooth operation and prevent overheating and damage.

6. Our extruder gearbox converts high-speed, low-torque power into low-speed, high-torque output by changing the size ratios and meshing arrangements of different gears, achieving the function of speed reduction.

Types of Gearboxes:

Based on customer requirements, gear reduction gearboxes can be classified according to the size of the output shaft, center distance of the output shaft, output speed, and torque. Alternatively, we can provide several commonly used types of gearboxes for customers to choose from.

Product Service

|

24-hour Hotline

No matter when and where to call we can find our service to you.

|

Pre-sales Consultation

We have 5 sales people online, and whether you have any question can be solved through online communication. |

After-sales Services

Receive products have any questions about the product, can look for us,we will help you deal with the the first time,to your satisfaction. |

Exhibition

Certificate

Company profile

ZheJiang Arrow Machinery Co., Ltd.is a company specializing in R&D, production, sales, application promotion of food engineering projects. As 1 of the largest scaled food processing equipment &whole plant engineering problem solvers in China, machines served for more than 970 companies, export to 116 countries, area, more than 20 years engineering team, we recognize that quality equals value, aims to create a great future together with global customers.

FAQ

1. Q: How about Arrow Machinery?

R: ZheJiang Arrow Machinery Co., Ltd. is a High-Tech company. Our firm is composed of a strong

team which has substantial experience in R&D, manufacture, technique and sales service and has

specialized in extruder industry for 10 years,leading screw barrel manufacturer in China.

2. Q:What’s Arrow machinery’s capacity?

R:Company is in strict accordance with CE and ISO9001 quality certification system.There are over 200

models of extruders and spare parts.

3. Q:What’s the delivery time?

R:For regular size, we have finished stock and semi-finished stock, 2 weeks max enough

for customized, normally within 20days .

4. Q:How about the gearbox quality and price?

R: top quality in China with competitive price and globle after-sale service

5. Q:what’s the life time and guarantee buy from Arrow machinery ?

R: 3~5years life time for nitriding ones and bimtallic ones will be longer

One year min. Guarantee.

6.Q:Where is Arrow Machinery factory and how to reach there?

R:NO.47 Chengbohu Road, Xihu (West Lake) Dis. District,HangZhou City, China. You can take the train or plane to HangZhou and we can pick you up.

7.Q:How to contact with you?

R:just reply to me if have any question.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Application: | Motor, Machinery |

|---|---|

| Function: | Distribution Power, Change Drive Torque, Change Drive Direction, Speed Changing, Speed Reduction, Speed Increase |

| Layout: | Cycloidal |

| Customization: |

Available

| Customized Request |

|---|

.shipping-cost-tm .tm-status-off{background: none;padding:0;color: #1470cc}

|

Shipping Cost:

Estimated freight per unit. |

about shipping cost and estimated delivery time. |

|---|

| Payment Method: |

|

|---|---|

|

Initial Payment Full Payment |

| Currency: | US$ |

|---|

| Return&refunds: | You can apply for a refund up to 30 days after receipt of the products. |

|---|

Calculation of Reduction Ratio in a Cycloidal Gearbox

The reduction ratio in a cycloidal gearbox can be calculated using the following formula:

Reduction Ratio = (Number of Input Pins + Number of Output Pins) / Number of Output Pins

In a cycloidal gearbox, the input pins engage with the lobes of the cam disc, while the output pins are engaged with the cycloidal pins of the output rotor. The reduction ratio determines the relationship between the number of input and output pins engaged at any given time.

For example, if a cycloidal gearbox has 7 input pins and 14 output pins engaged, the reduction ratio would be:

Reduction Ratio = (7 + 14) / 14 = 1.5

This means that for every 1 revolution of the input pins, the output rotor will complete 1.5 revolutions. The reduction ratio is a key parameter that influences the output speed and torque of the cycloidal gearbox.

History of Cycloidal Gear System Development

The history of cycloidal gear systems dates back to ancient times, with various forms of non-circular gears being used for specialized applications. The concept of the cycloidal gear system as we know it today, however, has evolved over centuries of engineering and innovation:

- Ancient Roots: The concept of using non-circular gears can be traced back to ancient civilizations, where devices like the “Antikythera Mechanism” (c. 150-100 BC) employed non-circular gear arrangements.

- Cam Mechanisms: During the Renaissance, engineers and inventors like Leonardo da Vinci explored mechanisms involving cams and followers, which are precursors to modern cycloidal gears.

- Cycloidal Motion Studies: In the 19th century, engineers and mathematicians like Franz Reuleaux and Robert Willis studied and developed mechanisms based on the principles of cycloidal motion.

- Early Cycloidal Gearboxes: The development of cycloidal gear systems gained momentum in the late 19th and early 20th centuries, with inventors like Emile Alluard and Louis André creating early forms of cycloidal gear mechanisms and gearboxes.

- Cycloidal Drive: The term “cycloidal drive” was coined by James Watt in the 18th century, referring to mechanisms that produce a motion resembling a rolling circle.

- Modern Cycloidal Gearboxes: The development of modern cycloidal gearboxes was further advanced by engineers like Ralph B. Heath, who patented the “Harmonic Drive” in the 1950s. This invention marked a significant step in the advancement and commercialization of precision cycloidal gear systems.

- Advancements and Applications: Over the decades, cycloidal gear systems have found applications in robotics, aerospace, automation, and other fields that require compactness, precision, and high torque capabilities.

The history of cycloidal gear system development reflects the contributions of many engineers and inventors who have refined and advanced the technology over time. Today, cycloidal gearboxes continue to play a crucial role in various industries and applications.

What is a Cycloidal Gearbox?

A cycloidal gearbox, also known as a cycloidal drive, is a type of gearing mechanism that utilizes the principle of cycloidal motion for power transmission. It consists of several components, including a high-speed input shaft, a set of cycloidal pins or rollers, and an outer stationary ring with lobed profiles.

The operation of a cycloidal gearbox involves a unique mechanism:

- Input Shaft: The high-speed input shaft is connected to the driving source, such as an electric motor. It transfers rotational motion to the cycloidal pins.

- Cycloidal Pins or Rollers: These pins or rollers are typically arranged around the input shaft in a circular pattern. As the input shaft rotates, the cycloidal pins also rotate, causing them to engage with the lobes on the outer stationary ring.

- Outer Stationary Ring: The outer ring has lobed profiles, and it remains stationary during operation. The lobes of the outer ring interact with the cycloidal pins or rollers, causing them to move in a unique motion known as epicycloidal or hypocycloidal motion.

The interaction between the cycloidal pins and the lobed profiles of the outer ring results in smooth and controlled motion transmission. The mechanism provides advantages such as high torque capacity, compact size, and precise positioning capabilities.

Cycloidal gearboxes are widely used in various applications, including robotics, automation, packaging machinery, and other industrial systems where high torque, precision, and compact design are essential.

editor by CX 2024-05-14

China best CZPT Arrow Professional High Torque Gearbox for Twin and Triple Extruder Machine wholesaler

Product Description

Overview

Product Description

Wide Selection of Gearbox Products

The gearbox usually adopts a general design scheme, but in special cases, the design scheme of the gearbox can be changed according to the demands of the user, and it can be modified into an industry-specific gearbox. In the design scheme of the gearbox, the parallel shaft, vertical shaft, general box, and various parts can be changed

Advantages

- Absorption of very high torques and axial forces

- No need for separate thrust housing & bearing.

- Easy alignment (screw directly fits into the vore of gear box)

- Easy to assemble & dismantle.

- Very heavy duty spherical roller thrust bearing is provided.

- Power saving. (you may save up to 20 % power.)

- Less requirement of space.

- For bigger sizes water cooling is provided

- No maintenance required except periodic oil level checking.

- Higher productivity

Features

- Twin Screw Extruder Gearboxes offer the dual shaft counter rotating. The range is available for various center distances

- The gearboxes are available with co-rotating and counter rotating variants

- To work under heavy loading force, the high level dissipation and oil lubrication system are provided. The axial roller type swivel thrust with the thrust bearing coupled in tandem way support the axial thrust

- High torque and high speed output rate

Processing Characteristics of Screw Shaft:

1.Suitable suggestion on material to ensure components performance and extend lifetime of products.

2.Professional technical team can provide surveying and mapping support.

3.All components are finished by CNC machine.

4.Sophisticated quality management system ensure superior quality.

Basic Info.

| Warranty: 1 year | Weight (KG): 500 KG |

| Place of Origin: HangZhou, China |

Gearing Arrangement: helical |

| ratio: 8-20 |

Output Torque: 2*176 |

| standard: JB/T8853-2001 |

Certificate: CE |

| Heat treatment: High-frequency Hardening |

Efficiency: 94%~98%(depends on the transmission stage) |

| Customized support:OEM ODM | Input/output shaft material 40Cr |

| Package: Wooden case |

Mount position: Flange, hollow shaft, CZPT shaft |

| After-sale:Online 24/7 Installation Xihu (West Lake) Dis. | advantage: excellent quality |

| Reduction radio: 3:1 |

Mount Position: Horizontal Foot Mounted Vertical |

| Input Speed: 1500 |

Output Speed: 500 |

Packaging & delivery

|

Packing: wooden case packing |

|

| Port: HangZhou Port |

Applications

X helical gear units for double-screw extruders with parallel drive shafts and the same direction of screw rotation are used mainly in the manufacture of granulates and the refining of raw plastics. Other areas of application include:

- Paint and lacquer industry

- Washing agent industry

- Foodstuff industry (e.g. bread, pasta)

- Animal-feed industry (dog, cat other animal food

Maintenance of the gearbox of the dual-screw extruder

1. The gear box of the dual-screw extruder should be well-ventilated, and the working environment temperature should be within the range of 5-35 °C.

2. Always check the oil quantity of the gear lubricating oil in the box to ensure that the transmission parts in the box are well lubricated.

3. Pay attention to check the bearing parts of the box frequently. The oil temperature of the oil tank of the transmission box should not exceed 70 ºC during operation.

4. The newly put into use gearbox needs to replace the lubricating oil after 250 hours of operation. The oil change time depends on the state of the oil. It is recommended to replace it after 4000-8000 hours of operation or once a year.

5. The gearbox of the dual-screw extruder needs to be regularly maintained and inspected once a year

Operating Process

1. The gear on the input shaft is driven by the motor and starts to rotate.

2. The rotating input gear meshes with other gears inside the gearbox, transmitting power.

3. Different-sized gears within the gearbox are combined to form a gear train. Through continuous meshing and rotation, the high-speed, low-torque power from the input shaft gradually converts into low-speed, high-torque output.

4. The output shaft is connected to the last gear and transfers the output torque to the load.

5. Gear reduction gearboxes typically include lubrication and cooling systems to ensure smooth operation and prevent overheating and damage.

6. Our extruder gearbox converts high-speed, low-torque power into low-speed, high-torque output by changing the size ratios and meshing arrangements of different gears, achieving the function of speed reduction.

Types of Gearboxes:

Based on customer requirements, gear reduction gearboxes can be classified according to the size of the output shaft, center distance of the output shaft, output speed, and torque. Alternatively, we can provide several commonly used types of gearboxes for customers to choose from.

Product Service

|

24-hour Hotline

No matter when and where to call we can find our service to you.

|

Pre-sales Consultation

We have 5 sales people online, and whether you have any question can be solved through online communication. |

After-sales Services

Receive products have any questions about the product, can look for us,we will help you deal with the the first time,to your satisfaction. |

Exhibition

Certificate

Company profile

ZheJiang Arrow Machinery Co., Ltd.is a company specializing in R&D, production, sales, application promotion of food engineering projects. As 1 of the largest scaled food processing equipment &whole plant engineering problem solvers in China, machines served for more than 970 companies, export to 116 countries, area, more than 20 years engineering team, we recognize that quality equals value, aims to create a great future together with global customers.

FAQ

1. Q: How about Arrow Machinery?

R: ZheJiang Arrow Machinery Co., Ltd. is a High-Tech company. Our firm is composed of a strong

team which has substantial experience in R&D, manufacture, technique and sales service and has

specialized in extruder industry for 10 years,leading screw barrel manufacturer in China.

2. Q:What’s Arrow machinery’s capacity?

R:Company is in strict accordance with CE and ISO9001 quality certification system.There are over 200

models of extruders and spare parts.

3. Q:What’s the delivery time?

R:For regular size, we have finished stock and semi-finished stock, 2 weeks max enough

for customized, normally within 20days .

4. Q:How about the gearbox quality and price?

R: top quality in China with competitive price and globle after-sale service

5. Q:what’s the life time and guarantee buy from Arrow machinery ?

R: 3~5years life time for nitriding ones and bimtallic ones will be longer

One year min. Guarantee.

6.Q:Where is Arrow Machinery factory and how to reach there?

R:NO.47 Chengbohu Road, Xihu (West Lake) Dis. District,HangZhou City, China. You can take the train or plane to HangZhou and we can pick you up.

7.Q:How to contact with you?

R:just reply to me if have any question.

| Application: | Motor, Machinery |

|---|---|

| Function: | Distribution Power, Change Drive Torque, Change Drive Direction, Speed Changing, Speed Reduction, Speed Increase |

| Layout: | Cycloidal |

| Customization: |

Available

| Customized Request |

|---|

.shipping-cost-tm .tm-status-off{background: none;padding:0;color: #1470cc}

|

Shipping Cost:

Estimated freight per unit. |

about shipping cost and estimated delivery time. |

|---|

| Payment Method: |

|

|---|---|

|

Initial Payment Full Payment |

| Currency: | US$ |

|---|

| Return&refunds: | You can apply for a refund up to 30 days after receipt of the products. |

|---|

How to Calculate Transmission Ratio for a Cycloidal Gearbox

Using a cycloidal gearbox can be very useful in a wide variety of situations. However, it’s important to understand how to use it properly before implementing it. This article discusses the benefits of using a cycloidal gearbox, how to calculate the transmission ratio, and how to determine the effects of dynamic and inertial forces on the gearbox.

Dynamic and inertial effects

Various studies have been done to study the dynamic and inertial effects of cycloidal gearboxes. These studies have been performed using numerical, analytical and experimental methods. Depending on the nature of the load and its distribution along the gear, a variety of models have been developed. These models use finite element method to determine accurate contact stresses. Some of these models have been developed to address the nonlinear elasticity of contacts.

Inertial imbalance in a cycloidal gearbox causes vibration and can affect the efficiency of the device. This can increase mechanical losses and increase wear and tear. The efficiency of the device also depends on the torque applied to the cycloidal disk. The effectiveness of the device increases as the load increases. Similarly, the nonlinear contact dynamics are also associated with an increase in efficiency.

A new model of a cycloidal reducer has been developed to predict the effects of several operational conditions. The model is based on rigid body dynamics and uses a non-linear stiffness coefficient. The model has been validated through numerical and analytical methods. The model offers drastic reduction in computational costs. The model allows for a quick analysis of several operational conditions.

The main contribution of the paper is the investigation of the load distribution on the cycloidal disc. The study of this aspect is important because it allows for an analysis of the rotating parts and stresses. It also provides an indication of which gear profiles are best suited for optimizing torque transmission. The study has been conducted with a variety of cycloidal gearboxes and is useful in determining the performance of different types of cycloidal gearboxes.

To study the load distribution on the cycloidal disc, the authors investigated the relationship between contact force, cycloidal gearboxes and different gear profiles. They found that the non-linear contact dynamics have a large impact on the efficiency of a cycloidal gearbox. The cycloidal gearbox is an ideal solution for applications that involve highly dynamic servos. It can also be used in machine tool applications and food processing industries.

The study found that there are three common design principles of cycloidal reducers. These are the contact force distribution, the speed reduction and the trochoidal profile of the cycloidal disc. The trochoidal profile has to be defined carefully to ensure correct mating of the rotating parts. The trochoidal profile provides an indication of which gear profiles are best for optimizing torque transmission. The contact force distribution can be improved by refining the mesh along the disc’s width.

As the input speed increases, the efficiency of the reducer increases. This is because contact forces are constantly changing in magnitude and orientation. A cycloidal reducer with a one tooth difference can reduce input speed by up to 87:1 in a single stage. It also has the ability to handle high-cycle moves without backlash.

Transmission ratio calculation

Getting the correct transmission ratio calculation for a cycloidal gearbox requires a good understanding of what a gearbox is, as well as the product that it is being used for. The correct ratio is calculated by dividing the output speed of the output gear by the input speed of the input gear. This is usually accomplished by using a stopwatch. In some cases, a catalog or product specification may be required. The correct ratio is determined by a combination of factors, such as the amount of torque applied to the mechanism, as well as the size of the gears involved.

A cycloidal gear is a type of gear tooth profile that can be represented using a spline. It is also possible to model a gear with a cycloidal profile by using a spline to connect points against the beginning of a coordinate system. This is important in the design and functionality of a gear.

There are many different gears used in machines and devices. These include the herringbone gear, the helical gear and the spiral bevel gear. The best transmission ratios are typically obtained with a cycloidal gearbox. In addition to ensuring the accuracy of positioning, a cycloidal gearbox provides excellent backlash. Cycloid gears have a high degree of mechanical efficiency, low friction, and minimal moment of inertia.

A cycloidal gearbox is often referred to as a planetary gearbox, though it is technically a single-stage gearbox. In addition to having a ring gear, the gearbox has an eccentric bearing that drives the cycloidal disc in an eccentric rotation. This makes the cycloidal gearbox a good choice for high gear ratios in compact designs.

The cycloid disc is the key element of a cycloidal gearbox. The cycloid disc has n=9 lobes, and each lobe of the disc moves by a lobe for every revolution of the drive shaft. The cycloid disc is then geared to a stationary ring gear. The cycloidal disc’s lobes act like teeth on the stationary ring gear.

There are many different gears that are classified by the profile of the gear teeth. The most common gears are the involute and helical gears. Most motion control gears include spur designs. However, there are many other types of gears that are used in various applications. The cycloidal gear is one of the more complicated gears to design. The cycloid disc’s outline can be represented using markers or smooth lines, though a scatter chart will also do.

The cycloid disc’s lobes rotate on a reference pitch circle of pins. These pins rotate 40 deg during the eccentric rotation of the drive shaft. The pins rotate around the disc to achieve a steady rotation of the output shaft.

The cycloid disc’s other obvious, and possibly more important, feature is the’magic’ number of pins. This is the number of pins that protrude through the face of the disc. The disc has holes that are larger than the pins. This allows the pins to protrude through the disc and attach to the output shaft.

Application

Whether you’re building a robot drive or you’re simply looking for a gearbox to reduce the speed of your vehicle, a cycloidal gearbox is a great way to achieve a high reduction ratio. Cycloidal gearboxes are a low-friction, lightweight design that has an extremely stable transmission. They are suitable for industrial robots and can be used in many applications, including positioning robots.

Cycloidal gearboxes reduce speed by using eccentric motion. The eccentric motion enables the entire internal gear to rotate in wobbly cycloidal motion, which is then translated back into circular rotation. This eliminates the need for stacking gear stages. Cycloidal gearboxes also have less friction, higher strength, and greater durability than conventional gearboxes.

The cycloidal gearbox is also used in a number of applications, including marine propulsion systems, and robot drives. Cycloidal gearboxes reduce vibration by using offset gearing to cancel out vibrations.

Cycloidal gears have lower friction, higher strength, and better torsional stiffness than involute gears. They also have a reduced Hertzian contact stress, making them better than involute gears for use with shock loads. They also have a smaller size and weight than conventional gearboxes, and they have a higher reduction ratio than involute gears.

Cycloidal gears are typically used to reduce the speed of motors, but they also offer a number of other advantages. Cycloidal gearboxes have a smaller footprint than other gearboxes, allowing them to fit into confined spaces. They also have low backlash, allowing for precise movement. Cycloidal gears have a higher efficiency, resulting in lower power requirements and lower wear.

The cycloidal disc is one of the most important components of the gearbox. Cycloidal discs are normally designed with a short cycloid, which minimizes the eccentricity of the disc. They are also designed with a shortened flank, resulting in better strength and less stress concentration. Cycloidal discs are typically geared to a stationary ring gear. The cycloid is designed to roll around the stationary ring pins, which push against the circular holes in the disc. Cycloidal gearboxes typically employ two degrees of shift.

Cycloidal drives are ideal for heavy load applications. They also have high torsional stiffness, which makes them highly resistant to shock loads. Cycloidal drives also offer a high reduction ratio, which can be achieved without the need for a large input shaft. They are also compact and have a high service life.

The output shaft of a cycloidal gearbox always has two degrees of shifting, which ensures that the input and output shafts always rotate at a different speed. The output shaft would be a pin casing around the drive disks, which would also allow for easy maintenance.

Cycloidal gearboxes are also very compact and lightweight, so they are ideal for use in industrial robots. The cycloidal gearbox reducer is the most stable, low-vibration reducer in industrial robots, and it has a wide transmission ratio range.

editor by CX 2023-11-21

China manufacturer P series planetary gearbox with high quality torque speed reducer lg washing machine gearbox increase torque gearbox with high quality

Warranty: 3 years

Applicable Industries: Hotels, Garment Shops, Building Material Shops, Manufacturing Plant, Machinery Repair Shops, Food & Beverage Factory, Farms, Energy & Mining, Construction works

Weight (KG): 50

Customized support: OEM, High Torque Planetary Gearbox Low backlash gearbox Planetary for Wind Turbe ODM, OBM

Gearing Arrangement: Planetary

Output Torque: Up to 260000Nm

Input Speed: 750-1500rpm

Output Speed: 0.19-60rpm

Certification: ISO9001-2008

Mount Position: Foot Mounted

Bearing: C & U

Packaging Details: Standard wooden case

Port: HangZhou Port, ZheJiang Port

Products Description Feature:1.P series planetary gear reducer adopts new open line planetary gear transmission, which makes rational use of internal and external combination and power split. Therefore, it has the characteristics of light weight, small volume, large transmission ratio, high efficiency, smooth operation, 10Z lg CZPT whirlpool original Washing machine parts reducer gearbox washing machine spare parts low noise and strong adaptability.2.The box body is made of nodular iron, which greatly improves the efficiency.The column property and anti-seismic property of the box body.3.Programming mode: concentric shaft input, helical gear input, bevel gear helical gear input, bevel gear input4.Output mode: inner flower field type, hollow shaft shrink disc type, outer flower field type, solid shaft flat field type5.Installation form: horizontal installation, vertical installation and torsion installation.6.P series products have 9-34 type specifications, Servo Motor BMG0703S0044 planetary transmission stage has 2 and 3. The speed ratio is 254000.Modular design, according to customer requirements to change the combination.7. Combinate with R ,K series can get larger speed ratioIf you need to customize, please click here Speed ratio range basic type 25 ~ 4000 torque range2.6 ~ 900knmpower range22 ~ 1920kwInstallation form:1. Horizontal installation / foot installation 2. Vertical installation / flange installation 3. Torsion arm installation.Output mode1. Hollow output shaft with shrink disc 2. Solid output shaft with flat key 3. Hollow shaft with involute spline 4. Solid shaft with involute spline For more models or customization, please click here! Click on the picture below for details Related Products Company Information Packing&Shipping Packaging:Chain+Plastic Bag+ Carton+Wooden case( If you have other requirements, we can customized according to customer requirements packaging. )Shipping :1.Most of the standard ones are in stock which we can send in 3-10 days after inspection and package.2. Customized products delivery time should be determined according to the number. Contact Us

What Is a Gearbox?

A gearbox is the mechanical system of an automobile that allows a vehicle to change gear smoothly. This arrangement of gears is highly complex, which helps to provide a smooth gear change. In this article, we will explore some of the different types of gearboxes, including the Epicyclic gearbox, the Coaxial helical gearbox, and the Extruder helical gearing. These are three of the most common types of gearboxes used in automobiles.

Gearboxes

Gearboxes help drivers choose the appropriate gear for the conditions. A lower gear produces the least speed, while a higher gear gives the maximum torque. The number of gears used in a gearbox varies to meet different demands on the road and load. Short gearing provides maximum torque, while tall gearing offers higher top speeds. These features combine to improve the driveability of a vehicle. But what is a gearbox?

The gearbox has a slew of components, including the bearings and seals. Among these components is the gearbox, which is subjected to wear and tear due to metal-to-metal contact. As a result, gearboxes require close monitoring. Various tests are used to assess the condition of gears, such as corrosion and wear. Proactive tests emphasize wear, contamination, and oil condition. However, there are also proactive tests, such as the ferrous density test and the AN test, which monitor additive depletion and abnormal wear.

The separating force is a key factor for the design of a gearbox. The primary radial measurement point should be oriented to monitor normal forces. The secondary measurement point should be located in the opposite direction of rotation from the primary radial measurement point. The separating force generated by a helical gear set is called tangential force. The primary and secondary radial measurement points should be positioned so as to provide information about both normal and tangential forces.

Manual gearboxes are often manual. The driver can control the synchromesh by using a selector rod. This rod moves the synchromesh to engage the gear. Reverse gears are not synchromesh because they are used only when the vehicle is at a standstill. In older cars, the first gear often lacked synchromesh due to cost or lack of torque. Drivers could still use first gear with a double-declutch.

Coaxial helical gearbox

The R series rigid tooth flank helical gearbox features high versatility and good combination. They have a wide range of motor power and allow for fine classification of transmission ratios. The R series gearbox has several advantages, including high efficiency, long service life, and low vibration. This series of gearbox can be combined with a wide range of reducers and variators. Its size and high performance makes it an ideal choice for applications that require maximum torque and load transfer.

The main feature of a helical gearbox is that it presents a fixed velocity ratio, even if the center gaps are not perfectly set. This is sometimes referred to as the fundamental rule of gearing. A helical gearbox is similar to paper spur gears in terms of radial pitch, since the shafts in the helical gearbox cross at an angle. The center gap of a helical gearbox is the same for both the left and right-handed counterparts.

The EP Series is another popular model of a Coaxial helical gearbox. This series has high torque and a maximum reduction ratio of 25.6:1. It is an ideal choice for the plastic industry, and CZPT offers an extensive range of models. Their center distance ranges from 112 mm to 450 mm. The EP Series has several models with different center distances. In addition to high torque and efficiency, this gearbox has low noise and vibration, and it is easy to assemble and disassemble.

Another type of Coaxial helical gearboxes is the planetary gearbox. They have a high efficiency and power density. Unlike coaxial helical gearboxes, planetary gearboxes have an axis on the same direction as the output shaft. They are easy to integrate into existing drive trains. In addition, they are compact and easy to integrate with existing drive trains. For servo applications, they are another great choice.

Epicyclic gearbox

An epicyclic gearbox is a type of automatic gearbox used to drive cars. Its primary advantage is its compact design, and it is more reliable and efficient than manual gearboxes. It is comprised of a sun gear and two planetary gears, encased in a ring gear called the Annulus. This system is useful for drivers who need to shift gears frequently, as they will become tired if the gears are suddenly changed.

An epicyclic gearbox consists of three different types of gears: ring gear, sun gear, and annular ring gear. The ring gear is the outermost gear and has angular-cut teeth on its inner surface. It is used in conjunction with planetary gears to provide high-speed ratios to vehicles. The sun gear also reverses the direction of the output shaft. This helps reduce transmission error.

An epicyclic gearbox uses multiple planets to transfer power between the planets. This type of gearbox is lightweight and features a high power density. This gearbox has several benefits over a standard single-stage parallel axis gearbox, including multiple load paths, unequal load sharing, and phased meshing. Furthermore, epicyclic gearboxes require more complex transmission error optimisation than their counterparts, including more than one stage.

The objective of epicyclic gearbox research is to provide the lowest transmission error possible. The process includes an initial design and detailed specification. The system is defined by its load spectrum and required ratio. Deflections of the elastic mesh are calculated to understand their strength and how much energy the system can handle. Finally, micro-geometric corrections minimize transmission error. These improvements are crucial to the overall efficiency of an epicyclic gearbox.

Extruder helical gearing

The helix in an extruder helical gearing is fixed at an angle, enabling more interaction with the shaft in the same direction as it moves. As a result, the shaft and the bearing are in constant contact for a long period of time. Typically, extruder helical gearing is used in applications where there is low excitement, such as steel, rolling mills, conveyors, and the oil industry. The bevel gear train also plays a role in these applications.

The CZPT AEX extruder drive gear is specifically developed for this specific application. The gears are compact and lightweight and offer exceptional power density and a long service life. These extruder gears are highly reliable, and they can be used in a wide range of applications, including rubber processing, food production, and recycling plants. CZPT offers both standard and custom gearing for your extruder.

Another advantage of helical gearing is its versatility. Since the helical gearing teeth are inclined at a specific angle, they can be adjusted to meet the specific needs of a given application. These gears also have the advantage of eliminating noise and shock from straight teeth. Unlike other gearing types, they are able to achieve a wide range of loads, from small to large. These helical gears are very durable and are the best option for high-load applications.

In addition to this, asymmetric helical gears have increased flexibility, while asymmetrical helical gears have lower flexural stiffness. The ratio of teeth to the shaft has a positive effect on the strength of the gear. Furthermore, asymmetrical helical gears are easier to manufacture. But before you purchase your next extruder gear, make sure you know what you’re getting into.

1 speed gearbox

CZPT Group Components produces the one speed gearbox. It has the potential to make cars more efficient and environmentally friendly. The gear ratio of a car’s drivetrain is crucial for reaching maximum power and speed. Typically, a one-speed gearbox delivers a maximum of 200 hp. But the speed at which a car can reach this power must be high to get the full benefit from the electric motor. So, how can a one-speed gearbox improve the speed and torque of a car?

A one-speed gearbox is a mechanical device used to switch between second and third gears. It can include multiple gear sets, such as a shared middle gear for switching between second and third gears. It can also have an intermediate gear set that represents a switchable gear in both partial transmissions. The invention also includes a mechanism that makes it easier to change gears. The patent claims are detailed below. A typical one-speed gearbox may include two parts.

Generally, a one-speed gearbox will have up to seven forward gears, with each of these corresponding to a different speed. A one-speed gearbox can have five different gear sets and five different gear levels. It can have synchronized gear sets or last-shelf gear sets. In either case, the gears are arranged in a way that maximizes their efficiency. If the gears are placed on opposite sides of a car, the transmission may be a two-speed one.

CZPT Transmission specializes in the production of high-speed gearboxes. The company’s Milltronics HBM110XT gearbox machine is the perfect tool for this job. This machine has a large working table and a heavy-duty load capacity, making it a versatile option for many kinds of applications. There are also a wide variety of CZPT gearboxes for the automotive industry.

China manufacturer Newstart Low Loss Reduce Buzz Noise Inductor Single Screw Hydraulic Planetary Gearbox 201 For Extruder Machine with Great quality

Warranty: 1 years

Applicable Industries: Manufacturing Plant, Machinery Repair Shops, Other

Weight (KG): 19 KG

Customized support: OEM

Gearing Arrangement: Planetary

Output Torque: as customer requirements

Input Speed: as customer requirements

Output Speed: as customer requirements

Product name: Planetary Gearbox

Keywords: Planetary Gearbox Precision

Application: Textile,Machinery,Power Tranmission,Packing Machine, Hot Sale Cast Iron Single Wheel Pulley with Swivel CNC…

Material: 20CrMnTi, 40Cr, 42CrMo…

Structures: Coupling, Bearing + Gear + Box…

Ratio: 3-1000 or as customer requirements

Packing: Carton or as customer requirements

Packaging Details: Carton or as customer requirements

Port: China, HangZhou

Specification Product Nameplanetary gearboxBrand NameNEWSTARTApplicable IndustriesServo MotorGearing ArrangementPlanetaryRatio i3,4, Factory direct sale high precision custom timing belt pulleys with keyway 5,6,7,8,10Input interfaceAccording to motor outputMax. radial load (N)9600Max. axial load (N)4800Rated input speed (r/min)2000Max. input speed (r/min)4000Noise (db)≤63Backlash – GTM Gearbox Rotary Mower Gearbox Transmission Gearbox For Tractor PTO Class P2 (arcmin)≤5No-load torque at 20oC (Nm)≤0.1Operating temperature (℃)-15 to +90Service life (h)≥20,000Protection grade (IP)IP54MOQ1 More Products Company Profile Semi-Automatic PET Bottle Blowing Machine Bottle Making Machine Bottle Moulding MachinePET Bottle Making Machine is suitable for producing PET plastic containers and bottles in all shapes. Exhibition Certifications FAQ Q: Are you a manufacturer or a trader? A: We are a professional factory with 16 years of production experience. Q: Are all motor types compatible with planetary reducers? A: Our planetary gear reducers are customized according to your motor mounting flange, all types of motors can be matched. Q: What is the warranty period of the product? A: The warranty period of the product is 18 months. Q: What is the delivery cycle of the product? A: The delivery time of general products is 20-25 days. Customized products in about 45 days. Please ask for specific delivery time before ordering. If you have other questions that are not clear, High quality MB000083 Center Bearing for CZPT CANTER MB000076 MB006207 12019-25403 MC86~13 0571 88828 1385811777816 you are welcome to contact us.

The Different Types of Gearboxes

There are many different types of gearboxes. Some brands have more than one type. In this article, we’ll discuss the planetary gearbox, the worm reduction gearbox, the shaft mounted gearbox, and the one speed gearbox. This article will also help you determine which type of gearbox is best for your vehicle. And don’t worry if you don’t know the terminology yet. We’ll explain each type in detail so that you know what you’re getting yourself into.

Planetary gearbox

Planetary gears have many advantages. The multiple gears in a planetary gearbox mesh simultaneously during operation. As such, they provide high efficiency and transmit high transmittable torque. These gears are widely used in various industries and are resistant to high shock loads and demanding conditions. CZPT is one of the companies that offer planetary gearboxes. Its products do not require special tools for assembly, and its scalable design minimizes safety stock.

Among the numerous benefits of planetary gearing is its compactness and lightweight. As such, it is suitable for wide applications with space and weight constraints. However, to truly appreciate its benefits, it is necessary to understand its mechanisms. Here are some of the most common details about planetary gearing:

The planetary gearbox has two mounted gears: an input shaft and an output shaft. Each gear has multiple teeth that are attached to a carrier and rotate with the input shaft. The carrier is connected to the output shaft. A planetary gear is mounted on both gears via a carrier. The carrier rotates in order to drive the planetary gear. The sun gear is often the input gear. The other gear is called the outer gear.

Planetary gearboxes are highly customizable. The size, mounting, and housing options vary, as do the reduction ratios and input speeds. Different types can be manufactured for different applications and include options such as electrical or mechanical preload. The final design of a planetary gearbox can be highly customized, based on the specifications of the application. By combining engineering excellence and ongoing innovation, planetary gearboxes provide years of trouble-free operation.

A planetary gearbox can be either an electric motor or a manual one. The latter has more features than the former, and can be used in applications where space is an issue. The primary features of a planetary gearbox include its backlash, torque, and ratio. Secondary features include noise, corrosion resistance, and construction. A planetary gearbox is a highly versatile gearbox that can drive anything from simple machinery to advanced electrical systems.

Worm reduction gearbox

The global worm reduction gearbox market report compiles key insights from the industry to help you improve your business strategy. This report will help you create a comprehensive business document that will enhance your company’s competitive edge. To obtain this report, visit our website now! Read our latest report to find out what you can expect from the global worm reduction gearbox market. Alternatively, request a sample copy for more details. Here is a sneak peek of the report:

Worm gears are made with different thread counts and are usually not matched with the CZPT standard. In general, a single thread worm should be used with a single thread worm. Worm gears have either right or left threads, and their thread count will be different as well. This type of gear is used to reduce the speed of a rotating shaft. The speed reduction ratio will be about 50 percent if the worms have the same thread count as the CZPT gears.

The standard gear set transfers power at the peak load point of a tooth, called the pitchline. The worm gear moves slowly against the wheel’s metal surface. The worm gear is also more complex than the standard gear because the worm is sliding rather than rolling. Worm gears are hard to lubricate. Moreover, the sliding contact between the gear and worm increases the complexity of the gear set. They can be a great solution for applications where noise is a significant factor.

The axial pitch and circular pitch of the worm are equal. The ratio of these two indices determines the speed of transmission. For a worm reduction gearbox to work, the axial pitch and the circular pitch must match. The pitch angle of a worm can either be left-handed or right-handed. The lead of a worm is the distance one thread travels in one revolution. The lead angle is the angle tangent to the thread helix of the cylinder’s pitch. When a worm mesh is reversed, the majority of the mesh will be on the receding arc.

Worm gears generate more heat than their counterparts, so it is important to choose a worm reduction gearbox carefully. You will want to choose the material and amount of lubricating oil carefully. Worm gears are generally made of tin bronze. The paired worms are hardened to HRC45-55. In general, they are durable, lasting up to ten years. But they will wear out – and they wear out – so you may want to consider some other factors.

Shaft-mounted gearbox

Shaft-mounted gearboxes are designed for a variety of mining and quarry applications. Their high reliability and low maintenance make them an excellent choice in these types of applications. Shaft-mounted gearboxes also feature an optional backstop device that prevents the unit from rotating in one direction. This makes them an excellent choice for applications where alignment accuracy is an issue. Here are some of the benefits of using a shaft-mounted gearbox:

Shaft-mounted gearboxes are typically constructed of aluminium, and come in sizes ranging from 050 to 125. They feature a variety of reduction ratios and ensure optimum efficiency in all operating conditions. New S series sizes, 140 and 150, extend the application range of shaft-mounted gearmotors. They are both backed by a two-year warranty. For even greater peace of mind, Shaft-mounted gearboxes are available with a range of warranty options.

The most common applications for a Shaft-mounted gearbox include traction-driven applications where a low-speed shaft is required for operation. They also are suitable for applications without a foundation, where the motor is mounted next to the reducer. To prevent the gear drive from rotating, a torque arm is attached between the motor and the shaft. Small-sized shaft-mounted gear drives are usually made without motor mount kits, which can make them an excellent choice for conveying light loads.

Another important feature of a Shaft-mounted gearbox is its mounting position. The reduced motion through the drive is redirected through the shaft, creating additional forces. These additional forces can affect the performance of the gearbox, causing vibrations and noise. Consequently, it is important to replace worn or damaged belts on a regular basis. Further, shaft-mounted gearboxes can be affected by problems with other components and amplify vibrations.

1 speed gearbox

CZPT Group Components produces one speed gearboxes. These transmissions are produced in the CZPT Group’s Kassel plant. They are compact and robust, and are designed for easy integration. The Bosch Rexroth GD1 one-speed gearbox is easy to install horizontally or vertically. The Plug and Drive system integrates the gearbox with the existing cooling system. There are many other benefits to this gearbox.

With an ID.3 electric drive motor, the maximum torque is delivered at 16,000 rpm. This single-speed transmission offers high power density and excellent noise-reduction, making it ideal for electric vehicles. The e-drive motor is extremely quiet and requires precision manufacturing. The e-drive motor also enables a wide range of driving conditions. It can reverse when needed, and reaches its maximum speed at 16,000.

The single-speed gearbox is a standard feature on most electric vehicles. Some electric vehicles, such as the Porsche Taycan, will be equipped with a two-speed gearbox. This gearbox offers more top speed and range, but it is more complex than a standard single-speed gearbox. CZPT doesn’t need to add complexity to its electric vehicles. After all, a 355 horsepower family wagon is not likely to need a dual-speed gearbox.

In addition to simplifying the transmission, the patent claims also address improvements in structural design. Fig. 5 shows a schematic representation of a transmission 50′, wherein gear sets Z1 and Z4 are exchanged between partial transmissions. This switch matrix also reflects the synchronized gears and lastshelf gears. Hydraulically betatigte Lamellenkupplungen (HBA) also form a last-shelf gear.

Another advantage of the patent claim is that it offers numerous functional freedoms, which is especially valuable in the design of an automobile. One of the patent claims identifies a tosatzlicher middle gear that allows a driver to switch between second and third gears, with a single gearbox. In a conventional one-speed transmission, the tosatzlicher middle gear is attached to the second and first part gearbox. The latter has a second and third gear.

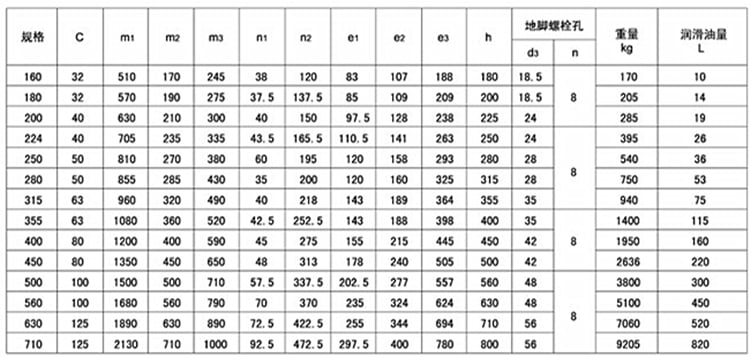

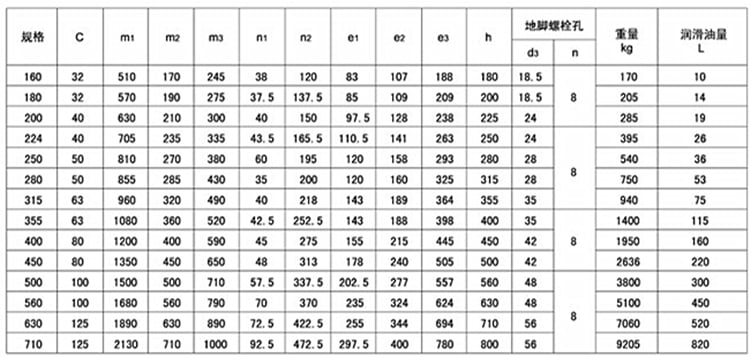

China best hard gearbox reducer zlyj series hdpe extruder reducer gearbox for agricultural machine near me shop

Model Number: ZLYJ

Gearing Arrangement: Helical

Output Torque: 652~34787N.m

Rated Power: 5.5~200kw

Input Speed: 600~1500rpm

Output Speed: 30~188rpm

working ambient temperature: -40~45 degree

Rotation: both forwards and backwards

Color: grey;blue;red(any color you want)

Application: extrudcer machine

Warranty: One Year

Ratio: 8; 10; 12.5; 14; 16; 18; 20

Certification: CE; ISO, CQM, ETC

Product name: ZLYJ series plastic extruder gearbox

Brand: GUOMAO

Type: ZLYJ

Packaging Details: Standard carton/Pallet/Standard wooden case (depends on order quantity).

Port: ZheJiang

hard gearbox reducer zlyj series hdpe extruder reducer gearbox for agricultural machine

1. Compact size, low noise2. Steady transmission3. High efficiencyZLYJ reducer is designed for plastic and rubber screw extruding machine with high-precision hard teeth surface.Material of the reducer is high strength alloy steel. Hardness of teeth surface is HRC54~62.Applicable scope A: Rotating speed of high speed shaft less than 1500/minB: Circular velocity of gear drive less than 20m/sC: Working condition temp. -40~45 degree

Product Name

ZLYJ series plastic extruder gearbox

Material

Gear and Shaft: low carbon alloy steel 20CrNi2Mo material, carbonization and quenching (Rockwell hardness HRC58-62), then through Germany NILES Gear Grinding Machine, gear precision is not less than 6 degree.

Input & Wholesale High Quality E Tricycle Electric Tuktuk Vehicle BLDC Motor Gearbox Output shaft: input shaft is Steel 20CrNi2Mo.The output shaft material is 40Cr

Bearing: domestic best bearing HRB (WZS,LYC) with heavy load capacity

Color

grey;blue;red(any color you want)

Brand

GUOMAO(TOP TEN IN CHINA)

Model No

ZLYJ112; ZLYJ133;ZLYJ146; ZLYJ173; ZLYJ180; ZLYJ200; ZLYJ225; ZLYJ250; ZLYJ280; ZLYJ315; ZLYJ330; ZLYJ375; ZLYJ395; Three phase high voltage motor Squirrel cage high voltage motor AC high voltage induction motor ZLYJ420; ZLYJ450;

Products Show Our ServicePursuing perfect quality and satisfying customers. With us, money is safe, business is safe. European quality, Chinese price. Professtional technician and service support.Our Company FactoryWorkshop

Warehouse

Team

Packing & DeliveryStandard export plywood case or carton. Inside the case: we use foaming agent to protect machines.

Our Certifications Customer PhotoOur products provide supports to companines all over the world: 1. Petrochina International 2. Sinopec International 3. Pakistan Lucky Cement4. South Korea Posco5. Swiss Buhler Machinery

FAQQ: Are you trading company or manufacturer ?A: We are factory.

Q: How long is your delivery time?A: Some series need 15-20 days , and some series is 30-40 days, it is according to quantity.

Q: Do you provide samples ? is it free or extra ?A: Yes, we accept sample order, but need to pay for sample and freight.

Q: What is your terms of payment ?A: Payment=1000USD, 30% T/T in advance ,balance before shippment.If you have any other problems, 12V 24V Planetary Gear BLDC Motor with dc worm reduction gear motor please kindly contact us -15961294115

Types of Gearboxes

There are several types of gearboxes. Some are known as helical gear reducers, while others are called planetary gearboxes. The article also discusses Continuously Variable Transmission (CVT) and helical gear reducer. If you are interested in purchasing a new gearbox, make sure to read our articles on these different types. If you are confused, consider reading our articles on planetary gearboxes and helical gear reducers.

planetary gearbox

The planetary gearbox has several advantages. Its compact design and light weight allows it to transmit high torques while remaining quiet. The gears are connected to one another through a carrier, which is typically fixed and helps transmit torques to the output shaft. Its planetary structure arrangement also reduces backlash and provides high rigidity, which is important for quick start and stop cycles and rotational direction change. Depending on the design and performance desired, planetary gearboxes are categorized into three main types:

The type of planetary gears used in a given application determines the overall cost of the unit. Manufacturers offer a range of prices, and they can help you determine which gearbox is right for your needs. You should also ask a manufacturer for the cost of a planetary gearbox. By asking about price and specs, you can avoid wasting money and time on a planetary gearbox that does not perform up to its potential.

A planetary gearbox is probably installed in your new car’s automatic transmission. For more information, consult your owner’s manual or call the dealer’s service department. This type of gearbox is more complex than other types of gearboxes, so if you don’t know much about them, do an internet search for “planetary gearbox.”

The teeth of a planetary gearbox are formed by the stepping motion of two gears: the sun gear and the inner ring. The sun gear is the input, while the planetary gears rotate around the sun gear. Their ratio depends on the number of teeth and the space between the planets. If you have a 24 tooth sun gear, the planetary gears’ ratio will be -3/2. The sun gear is also attached to the axle.

Another advantage of a planetary gear system is that it can generate high torques. The load is shared among multiple planet gears. This makes the gears more resilient to damage. A planetary gearbox can be as high as 332,000 Nm, and can be used in vehicles and industrial applications requiring medium to high torque. A planetary gear system is a great alternative to a traditional transmission. So, how does it work?

helical gearbox

The main difference between the helical gearbox and the spur gear is the center distance between the teeth. The helical gearbox has a larger pitch circle than the spur gear and thus requires a radial module. In addition, the two types of gears can only be made with the same tooth-cutting tool as the spur gear. However, the helical gearbox is more efficient in terms of production costs.

The helical gearbox is a low-power consumption, compact type of gearbox that is used for a wide range of industrial applications. They are highly durable and withstand high loads with utmost efficiency. The helical gearbox can be manufactured in cast steel and iron for small and medium units. This type of gearbox is also commonly used for crushers, conveyors, coolers, and other applications that need low power.

The helical gear has many advantages over the spur gear. It produces less noise. It has less friction and is less likely to wear out. It is also quieter than spur gears. This is because multiple teeth are in mesh. Because the teeth are in mesh, the load is distributed over a larger area, resulting in a smoother transition between gears. The reduction in noise and vibration reduces the risk of damaging the gear.

The helical gear’s axial excitation force is obtained using a linearized equation of motion in the rotational direction. The damping coefficient of the equation is 0.07. The helical gear is made up of a steel shaft with a diameter of 20 mm and a 5 mm thick aluminum plate. The stiffness of the bearing is 6.84 x 107 N/m. The damping force of the plate is 2,040 kg/m2/s.

The worm gearbox has a better efficiency ratio than the helical one, but it is less efficient in low-ratio applications. In general, worm gearboxes are more efficient than helical gearboxes, although there are some exceptions to this rule. A helical gearbox is better for applications that require high torque. It may also be more economical in the long run. If you are considering a helical gearbox, consider the advantages it has over worm gearboxes.

helical gear reducer

A helical gear reducer for a machine’s gearbox is an integral component of the drive system. This unit amplifies torque and controls speed and, therefore, compliments the engine by rotating slower than the engine’s input shaft. A helical gear reducer is a compact gearbox component that is used in industrial applications. A variety of sizes is available to suit various machine configurations. The following sections will discuss some of the different types available.

Designed by experts and engineers, a helical gear reducer is a surprisingly small and light gear that satisfies the needs of many machine applications. It features a large transmission torque, a low starting and running speed, and a fine classification of transmission ratios. A helical gear reducer is lightweight and easily connected to other gears, and it features a high technical content.

In order to avoid errors and poor performance, regular maintenance is a must. The proper lubrication of the gear reducer can minimize failures, errors, and poor performance. Every gear reducer manufacturer sells a suitable lubricant, which must match the properties of the machine’s drive mechanism. It is also advisable to check the lubrication regularly to avoid any deterioration of the unit’s performance.

While the worm gearbox may be better for applications where torque is high, the helical gear reducer offers greater efficiency at lower cost. Although worm gearboxes may be cheaper initially, they are less effective at higher ratios. Even if the worm gear is more expensive to buy, it still offers 94% efficiency, which makes it more cost-effective. There are some significant advantages to both types of gearboxes.

The main advantage of a helical gear reducer over a spur gear is its smoother operation. Unlike spur gears, which have teeth that are straight, helical gears have angled teeth that gradually engage with each other. This helps ensure that the gear does not grind or make excessive noise when it turns. Additionally, they are less commonly used in automation and precision machinery. They are often used in industrial applications.

Continuously variable transmission

A Continuously Variable Transmission (CVT) is an automatic transmission that can run through a vast number of gears. Unlike a standard automatic transmission, it can run at any speed, even at a low rev. The CVT is also capable of running at infinitely low gears. Its basic function is to provide different torque ratios to the engine. In addition to delivering power, CVTs have other benefits.

One of the major advantages of a CVT is its simplicity. Its simplicity translates into fewer moving parts, which means less maintenance. The CVT’s simplicity also means that it can handle a wide variety of different types of road conditions and driving styles. In addition to being a great alternative to a traditional automatic transmission, CVTs can be used on many other types of vehicles, including tractors, snowmobiles, motor scooters, and power tools.

A CVT is much smoother than a conventional automatic transmission. It never has to hunt for a gear. It also responds well to throttle inputs and speed changes. Both of these technologies are available on many modern vehicles, including the Nissan Rogue and Mazda CX-5. It’s important to note that each of these transmissions has its pros and cons. So, if you’re looking for a car with a CVT, make sure to read the reviews. They’ll help you decide which transmission is right for you.

Another advantage of a CVT is its fuel efficiency. Many cars now feature CVTs, and they’re becoming increasingly popular with automakers. In addition to fuel efficiency, most cars with CVTs also have a smoother ride. There’s no more sudden downshifts or gear hunting. This makes driving a lot easier. And, the added benefits of smoother driving make CVTs the ideal choice for many drivers.

Although a CVT is more common among Japanese car manufacturers, you’ll find CVTs on European car models as well. The Mercedes-Benz A-Class, B-Class, and Megane are some examples of vehicles that use this technology. Before making a decision, consider the reliability of the model in question. Consumer Reports is a good resource for this. It also offers a history of use and reliability for every type of car, including the Honda Accord.

China manufacturer & factory supplier for china in Gwalior India supplier ZLY 710 630 heavy duty industrial China gear reducer gearbox for steel rolling machine With high quality best price & service

Company & distributor of roller & wire rope stop chains. Varieties of chains consist of alloy, high tensile transport, high take a look at & proof coil chains. Programs incorporate log chains, cargo lashings, pipe line handing, tailgates, guard rails & switch chains.guarantees the security and regularity of the essential perform of elements.

Overview

Quick Details

- Applicable Industries:

-

Producing Plant

- Pole:

-

One particular/Two/Three Phase Pace Reducer

- Ratio:

-

one.twenty five-6.3

- Housing Content:

-

Solid Iron

- Operating temperature:

-

-forty~45℃

- Software:

-

mining, chemical industry,steel metallurgy,lifting transpor and ect.

- Procedure:

-

Carburizing, Nitriding , Grinding

- Efficiency:

-

94%~98%

- Mounting Place:

-

Horizontal,Vertical,Flange

- Coloration:

-

Blue,Green,Gray,Red

- Type:

-

weighty industrial China equipment reducer gearbox for steel rolling machine

Source Capability

- Provide Capability:

- 3000 Established/Sets per 12 months industrial China gear reducer gearbox for metal rolling equipment

Packaging & Delivery

- Packaging Details

- sea worthy wooden case for ZLY 710 630 weighty obligation indEPG Equipment is positioned in XiHu Location HangZhou Zhejiang ,China. It is 30km from our manufacturing unit to HangZhou worldwide airport. ustrial China gear reducer gearbox for steel rolling machine

- Port

- Qingdao

-

Guide Time

: -

Amount(Bags) 1 – 10 >10 Est. Time(times) eighteen To be negotiated

Online Customization

Solution Description

Z Series Helical Equipment Reducer

Z (ZDY, ZLY, ZSY, and ZFY) serieshard tooth surface cylindrical gear reducer

D (DBY and DCY) series hard tooth surface cone equipment reducer

EPG——industrial gearbox producers

Chinese electric motor speed reducer is extensively used in mining machinery, chemical sector,steel metallurgy, light-weight market,environmental protection, paper creating, printing, lifting transportation, food industry and so on.

Main Series Product: R series helical gear reducer, K collection spiral bevel equipment reducer, NGW, P collection planetary reducer, H B sequence gearbox, Z (ZDY, ZLY, ZSY, and ZFY) serial hard tooth surface cylindrical gear reducer, D (DBY and DCY) serial hard tooth surface cone equipment reducer, cycloid reducer, etc. Meanwhile, map sample processing organization can be undertaken.

Attribute:

-

Relevant to the metallurgical,power generation,water therapy,design,chemical,paper,

textiles,drugs,food and other industries.

-

The transmission effectiveness of single-phase can reach up to 98%, two-stage caThe centering equipment is element of the worm-equipment assembly line. An operator loads the reducer housing and bearing protect, and the EPG Team PTO shafts can be employed for speeds up to one thousand rpm. The greatest functioning length of the PTO shafts varies in accordance to the size of the tubes The assortment of the PTO shafts of RPG Group contains 4 series , according to the tube shape device decides the spacing in between output bearing seats.n reach ninety six%, three-stage can reach ninety four%.

-

The gear processed by Carburizing & Grinding with higher precision.

-

Substantial precision equipment, continual transmission, large load ability

-

Long service lifestyle.

- 1 Two Three Stage Pace Reducer

Specification

ZLY 710 630 weighty duty industrial China equipment reducer gearbox for steel rolling machine:

(remember to contact us for a lot more sorts & product)

Mounting Diamensions

Model assortment for equipment box transmission:

Closely using the excellent reduction ratio.

Reduction ratio = servo motor pace / reducer output shaft velocity

Torque calculation: Torque calculation is extremely essential for the lifestyle of reducer, and pay interest to whether the greatest torque value (TP) of acceleration exceeds the greatest load torque of the reducer.

The applicable electricity is typically the applicable electricity of the servo types on the industry, the applicability of the reducer is quite large, the working coefficient can be preserved above 1.2, but the selection can also be based mostly on their own needs to choose. Cylindrical Marine Gearbox Gear Pace Reducer.2 ratio ZLY180 Cylindrical Marine Gearbox Equipment Speed Reducer. ZLY 710 630 heavy obligation industrial China gear reducer gearbox for steel rolling equipment.

| Driven devices | |||

| Squander h2o treatment | Thickeners,filter presses,flocculation apparata,aerators,raking equipment,merged longitudinal and rotary rakes,pre-thickeners,screw pumps,h2o turbines,centrifugal pumps | Dredgers | Bucket conveyors, dumping products, carterpillar travelling gears, bucket wheel excavators as pick up, bucket wheel excavator for primitive content, cutter head, traversing gears |

| Chemical market | Plate bending machines, extruders, dough mills, rubbers calenders, cooling drums, mixers for uniform media, agitators for media with uniform density, toasters, centrifuges | Metal operating mills | plate tilters, ingot pushers, winding machines, cooling bed transfer frames, roller straigheners, desk continuous intermittent, roller tables reversing tube mills, shears ongoing, casting motorists, reversing blooming mills |

| Metal working mills | Reversing slabbing mills. reversing wire mills, reversing sheet mills, reversing plate mill, roll adjustment drives | Conveyors | Bucket conveyors, hauling winches, hoists, belt conveyors, good lifts, passenger lifts, apron conveyors, escalators, rail travlling gears |

| Frequency converters | Reciprocating compressors | ||

| Cranes | Slewing gears, luffing gears, travelling gears, hoisting equipment, derricking jib cranes | Cooling towers | Cooling tower fans, blowers axial and radial |

| Cane sugar manufacturing | Cane knives, cane mills | Beet sugar generation | Beet cossettes macerators, extraction vegetation, mechanical fridges, juice boilers, sugar beet washing equipment, sugar beet cutter |

| Paper machines | Pulper drives | Cableways | Content ropeways, ongoing ropeway |

| Cement sector | Concrete mixer, breaker, rotary kilns, tube mills, separators, roll crushers | ||

Engineering

Chinese Pace Reducer is a mechanical transmission in a lot of fields of the nationwide economy. The solution classes coated by the business consist of all types of equipment reducer, planetary gear reducer and worm gearbox, as properly as various special transmission gadgets this kind of as pace growing unit, pace manage Products, such as different sorts of versatile transmission products, these kinds of as compound transmission. Items and providers in the area of metallurgy, nonferrous metals, coal, developing resources, ships, water conservancy, electricity, building machinery and petrochemical industries.

In all fields of national economic system and countrywide defense sector, gearbox merchandise have a wide selection of apps. Meals light-weight market, electric equipment, development machinery, metallurgy equipment, cement machinery, environmental security equipment, digital appliances, road development machinery, drinking water conservancy machinery, chemical machinery, mining equipment, conveyor equipment, building resources machinery, rubber equipment, petroleum equipment and other industries have powerful need of Reducer items. ZLY 710 630 hefty responsibility industrial China equipment reducer gearbox for metal rolling device.

Packaging & Transport

Company Details

Launched in 1995, HangZhou Ever-Power Power machinery Co.,Ltd has 22 many years of reducer creation knowledge and credibility. The organization has professional engineer team, sophisticated technology manufacturing and expert workers, with located in HangZhou of ZheJiang province which has solid industrial foundation and produced transportation.

FAQ

1.Q:Are you the manufacturing facility or buying and selling company?

A:We are the skilled Manufacturing facility with 22 several years of experience.

2.Q:Can you customize according to our needs?

A:Of course, we can design and style nonstandard goods according to customer’s drawing and sample.

3.Q:How extended is the shipping and delivery date?

A:10-20 operating days.

four.Q:In which is your factory?

A:We are in HangZhou of ZheJiang Province, you can get listed here by large velocity practice or fly to Jinan.

Welcome to pay a visit to us!

China manufacturer & factory supplier for NMRV063 in Valencia Venezuela motovario Worm Gearbox Speed Reducer Machine With high quality best price & service

Our abilities go far outside of the scope of our catalog. Dependent on buyer desire, we now stock solid collars with oversized bores for apps the place the common tolerance does not allow for sufficient clearance. We also offer different finishes for solid and break up collar such as yellow zinc, nickel and chrome. Several are even stocked for off-the-shelf delivery. We also manufacture and inventory sound collars with 2 set screws, with thru holes, and with no holes. Collars are offered in inch and metric measurements. Heavy collection clamp-type collars and threaded collars are also available. We can even supply sq. bore collars for quantity demands. And if your particular needs repeat frequently, we are happy to stock components for scheduled releases. Whatsoever your collar requirements, Lucas Industrial is your provider for substantial top quality price – successful elements.Owing to our sincerity in offering very best services to our clients, comprehending of your demands and overriding sense of accountability towards filling buying demands,a specialized supplier of a complete selection of chains, sprockets, gears, gear racks, V-belts, couplings and reducers, pto shaft, agricultural gearboxes….

Overview

Quick Particulars

- Relevant Industries:

-

Production Plant, Machinery Fix Retailers

- Gearing Arrangement:

-

Worm

- Output Torque:

-

66N.M~~304N.M

- Input Speed:

-

1400rpm

- Output Speed:

-

14~~186rpm

- Spot of Origin:Zhejiang, China

- Model Name:

-

OEM

- Model Variety:

-

NMRV075

- Rated Energy:

-

.25~~4.0kw

Our organization has solid economic strength, builds up a technician staff contingent with higher good quality, possesses the production assembly line of technicalization in China and perfect technique checking on product quality and runs marketing networks all through the place.

- When compared to other varieties of gears, worm gears are special and have extremely distinctive attributes and utilizes. This put up will target on the rewards of worm gears. For a record of common worm gear apps, you should see worm equipment abilities. Speed ratio:

-

seven.5/10/15/twenty/25/30/40/50/60/eighty/100

- Housing content:

-

Aluminium alloy

- Worm gear material:

-

chromium alloy 20CrMnTi

- Worm wheel materials:

-

bronze ZQsn10-one

- Colour:

-

Blue/Silver/Coustomzied

- Certification:

-