Product Description

INTRODUCTIN FOR GEARBOX TMG5713

1.Over view

The CHINAMFG 5713 type hydraulic transmission (hereinafter referred to as the transmission) consists of a YJH315 type hydraulic torque converter and a transmission with 4 CHINAMFG gears and 3 backward gears.

YJH315 The hydraulic torque converter is a single-stage two-phase integrated torque converter, with the characteristics of high efficiency and large torque change ratio. The gearbox is downshaft type, with the front 4 and rear 3 shift function, built-in working oil pump, external force port.

2. Main technical parameters

| Rated input power of the matching engine | 75kW |

| Rated input speed of the matching engine | 2400r / min |

| Input shaft steering (facing the transmission output) | counter clock wise |

| Working fluid | No.6 or No.8 hydraulic transmission oil |

| Main oil pressure and retaining oil pressure | 1.6MPa~1.9MPa |

| Torque converter oil inlet pressure | 0.4MPa~0.8MPa |

| Torque converter oil return pressure | 0.22MPa~0.4MPa |

| Working oil temperature | 80ºC ~100ºC |

| Rated voltage of the solenoid valve | DC24V |

About TMG

CHINAMFG is a professional trackless mining equipment, engineering equipment manufacturer.Our production base is located in HangZhou, ZheJiang .

Our products include: underground trackless mining equipment (underground loaders, underground mining trucks, utility vehicles, drill jumbos, drivetrain system transmission, torque converter, axle); engineering equipment ( wheel loaders, backhoe loaders, excavators, telescopic handlers,graders, articulated dump trucks); drive-train system (transmission, torque converter, axle).

Besides,as a technology oriented enterprise, we also provide customers with solutions including drive-train system customization, vehicle transformation and project contracting etc.

| Improvement | |||||||

| The torque converter is easy to heat up | |||||||

| Inability to climb hills | |||||||

| Climbing long slopes is prone to overheating | |||||||

| Punch | |||||||

| Easy to burn the friction plate | |||||||

| Loud noise | |||||||

| Cause Analysis | |||||||

| Small horse-drawn cart | |||||||

| The hydraulic flow of the charging oil is low and the pressure fluctuates greatly | |||||||

| Comparison with Top Euro brand | |||||||

| Customized design to solve customer pain points | |||||||

| Short lead time, 3 months | |||||||

| Electrically controlled shifting and automatic shifting mode are adopted to reduce shifting impact and protect gears from damage | |||||||

| Hydraulic torque converter has large circulation, large transmitted torque, large traction and strong climbing ability. Change | |||||||

| Torque is not easy to heat up. | |||||||

| The clutch structure is improved to reduce the friction plate burning phenomenon caused by the inaccurate control of the engagement time of the 2 clutches during the shifting process. | |||||||

| The gear is thickened to improve the reliability of the gearbox. Higher reliability and longer life. |

| Payload 6~7 ton Calculation details | ||||||||

| Diesel Engine Model | kW | Torque Converter |

Transmission | Traction kN | 1st km/h | 2nd km/h | 3rd km/h | 4th km/h |

| Deutz BF6M 1013EC165KW |

165 | YJ330 (C273.1) |

RC33429 | 175.53 | 4.87 | 9.68 | 18.28 | 25.66 |

| Deutz BF6M 1013EC165KW |

165 | YJ330 (C273.1) |

RC33428 | 178.74 | 4.79 | 9.52 | 17.97 | 24.57 |

| CUMMIS B67CS4 | 162 | YJ330 (C273.1) |

RC33429 | 156.47 | 4.84 | 9.63 | 17.12 | 25.04 |

| CUMMIS B67CS4 | 162 | YJ330 (C273.1) |

RC33428 | 166.15 | 4.56 | 9.08 | 17.19 | 23.59 |

| Volvo TAD850VE | 162 | YJ330 (C273.1) |

RC33429 | 159.71 | 5.06 | 10.28 | 18.82 | 27.53 |

| Volvo TAD850VE | 162 | YJ330 (C273.1) |

RC33428 | 169.57 | 4.76 | 9.44 | 17.72 | 24.11 |

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Application: | Machinery, Wheel Loader;Backhoe Loader |

|---|---|

| Function: | Change Drive Torque, Speed Changing, Speed Reduction, Speed Increase |

| Layout: | Cycloidal |

| Hardness: | Hardened Tooth Surface |

| Installation: | Horizontal Type |

| Step: | Four-Step |

| Customization: |

Available

| Customized Request |

|---|

Efficiency of Cycloidal Gearboxes in Power Transmission

Cycloidal gearboxes offer relatively high power transmission efficiency compared to other types of gearboxes. The efficiency of a cycloidal gearbox depends on various factors, including the design, quality of components, lubrication, and load conditions.

Typically, the power transmission efficiency of a cycloidal gearbox ranges from 85% to 95%. However, this can vary based on several factors:

- Number of Reduction Stages: Multi-stage cycloidal gearboxes may experience slightly lower efficiency due to multiple gear meshing interactions.

- Quality and Design: Well-designed and precision-manufactured cycloidal gearboxes tend to exhibit higher efficiency.

- Lubrication: Proper lubrication is crucial for reducing friction and enhancing efficiency. Insufficient or deteriorated lubrication can lead to efficiency losses.

- Load Conditions: Higher loads and torque levels can lead to higher friction and lower efficiency. Properly matching the gearbox to the application is essential.

Despite minor efficiency losses compared to some other gearbox types, the benefits of compactness, high torque density, and precise motion control often outweigh the efficiency considerations in many applications.

Maintenance Requirements for Cycloidal Gearboxes

Maintaining cycloidal gearboxes is essential to ensure their optimal performance and longevity. Here are some maintenance practices to consider:

- Lubrication: Regular lubrication is crucial to prevent wear and friction between moving parts. Use high-quality lubricants recommended by the gearbox manufacturer.

- Inspections: Regularly inspect the gearbox for signs of wear, damage, or oil leakage. Address any issues promptly to prevent further damage.

- Cleaning: Keep the gearbox clean and free from debris that could interfere with its operation. Cleanliness helps prevent contamination and wear.

- Torque Checks: Periodically check the tightness of fasteners and bolts to ensure they are properly secured. Loose fasteners can lead to misalignment and reduced performance.

- Seal Maintenance: Check and maintain seals to prevent oil leakage. Damaged seals should be replaced promptly to avoid lubricant loss.

- Temperature Monitoring: Monitor the operating temperature of the gearbox to ensure it remains within the recommended range. Excessive heat can lead to premature wear.

- Alignment: Ensure that the gearbox is properly aligned with other components to prevent misalignment-related issues.

- Regular Service: Follow the manufacturer’s recommended service intervals for more in-depth inspections and maintenance tasks.

Regular and proactive maintenance can extend the lifespan of cycloidal gearboxes, minimize downtime, and maintain their efficiency and performance over time.

Principle of Cycloidal Gearing

Cycloidal gearing is a mechanism that utilizes the unique shape of cycloidal discs to achieve motion transmission. The principle involves the interaction between two main components: the input disc and the output disc.

The input disc has lobes with pins, while the output disc has lobes with matching holes. The lobes on both discs are not perfectly circular but are shaped in a cycloidal profile. As the input disc rotates, the pins on its lobes engage with the holes in the output disc’s lobes.

As the input disc rotates, the pins move along the cycloidal paths, causing the output disc to rotate. The interaction between the pins and the holes results in smooth and continuous motion transfer. The unique shape of the cycloidal profile ensures that there is always at least one point of contact between the pins and the holes, allowing for efficient torque transmission and reduced wear.

Cycloidal gearing provides advantages such as high torque capacity, compact size, and precision motion. However, due to the complex shape of the components and the continuous engagement, manufacturing and assembly of cycloidal gearboxes can be intricate.

editor by CX 2024-04-22

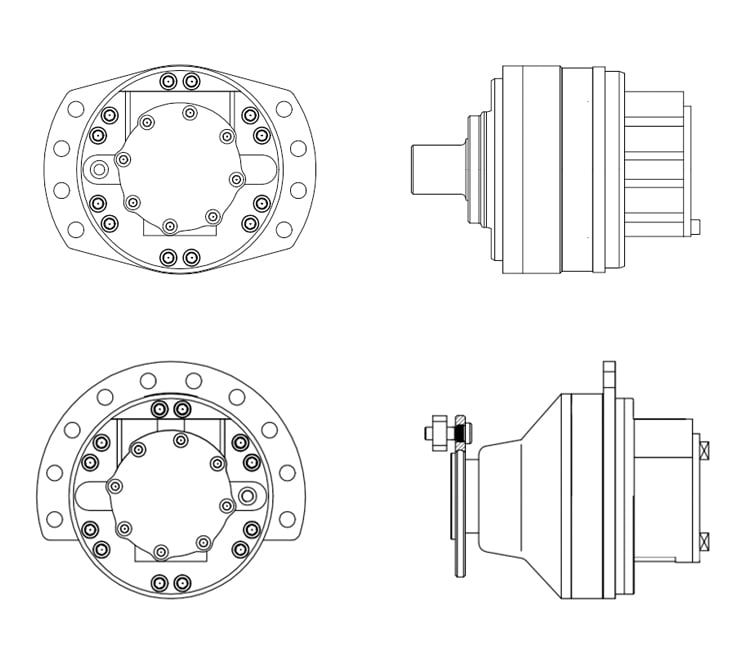

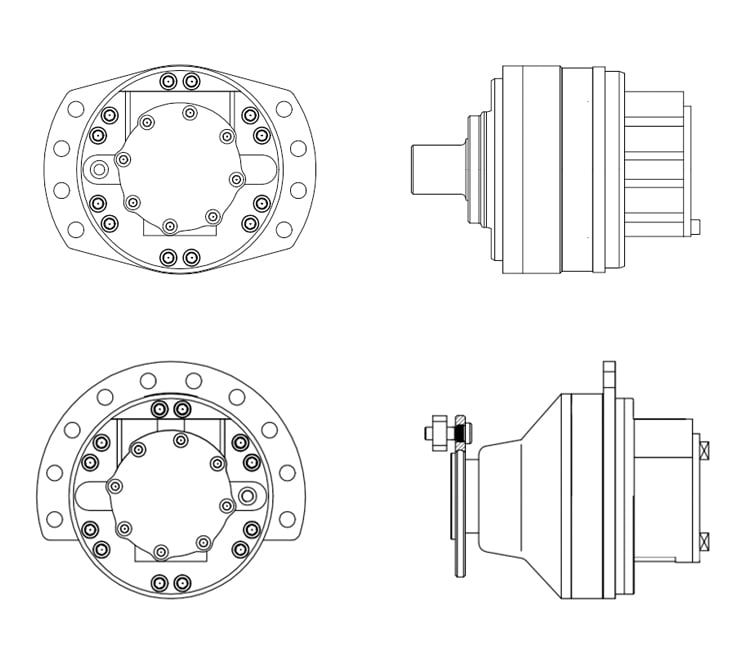

China Custom Pmb6.5 Pmb7.1 Pmb7.5 Hydraulic Gearbox for Concrete Mixer automatic gearbox

Product Description

PMB6.5 PMB7.1 PMB7.5 Hydraulic Gearbox For Concrete Mixer

The Gearbox reducer for concrete mixer trucks is used in the transmission system of concrete mixer trucks.

The reducer adopts planetary gear transmission, which has the characteristics of stable torque driving, compact structure, less maintenance and long service life. The reduction gear body can be bolted to the mounting bracket of the frame or directly connected to the frame and connected to the drum through the output flange. The output flange allows for a certain angle of oscillation in all directions to meet the requirements of various complex conditions. This reducer acts as a front support for the drum and drives the drum to rotate through the output flange.

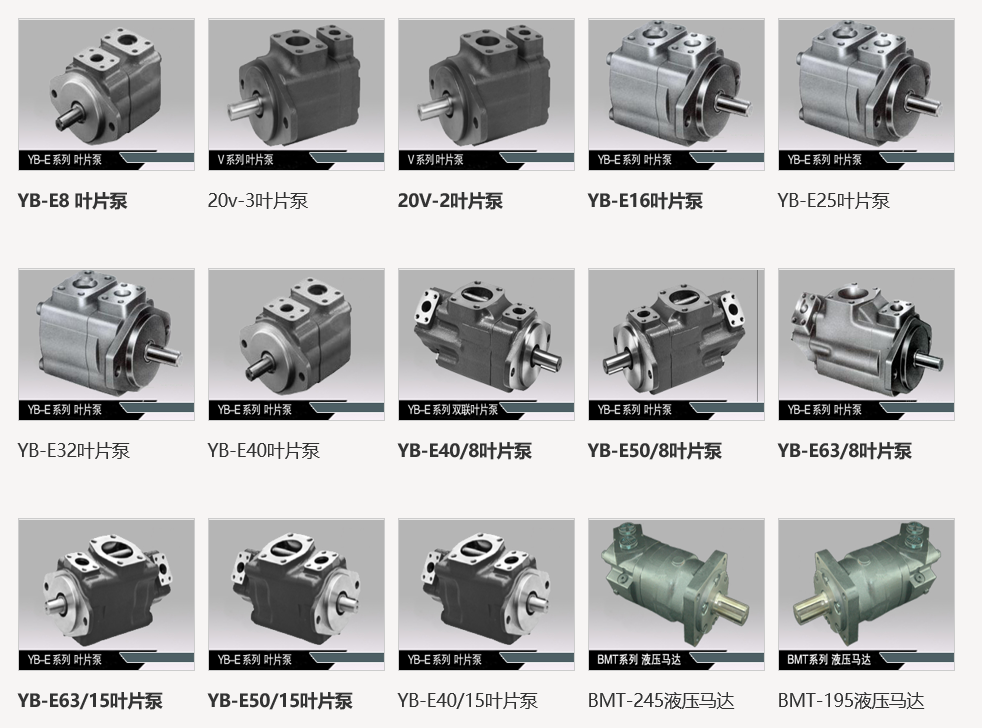

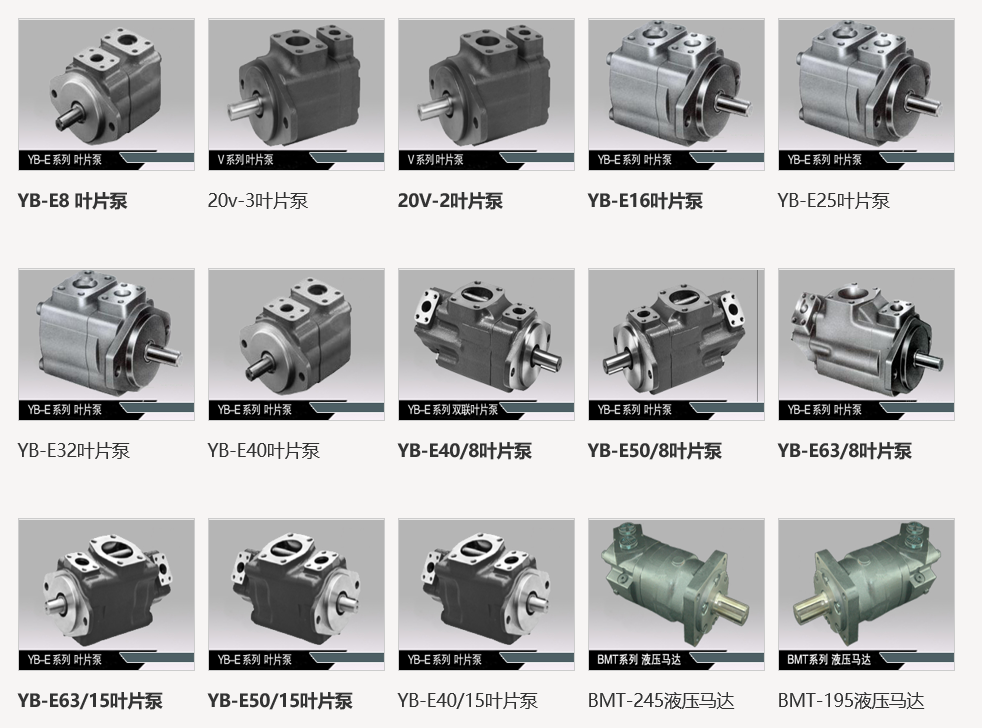

We could supply the CHINAMFG hydraulic pump and motor, also the inner spare parts as below model:

1 A8VO: A8VO55,A8VO80,A8VO107,A8VO160

2,A2FO: A2FO5 A2FO10 A2F12 A2FO16 A2FO23,A2FO28,A2FO32,A2FO45,A2FO56,A2FO63 A2FO80

3,A4VSO: A4VSO40,A4VSO45,A4VSO56,A4VSO71,A4VSO125,A4VSO180,A4VSO250,A4VSO500,

4,A4VG: A4VG28,A4VG45,A4VG50,A4VG56,A4VG71,A4VG125,A4VG180,A4VG250

5,A6V: A6V55,A6V80,A6V107,A6V160,A6V225,A6V250

6,A7V: A7V16,A7V28,A7V55,A7V80,A7V107,A7V160,A7V200,A7V250

7,A8V: A8V55,A8V80,A8V107,A8V115,A8V172

8,A10VSO: A10VSO10,A10VSO18 A10VSO28,A10VSO43,A10VSO45,A10VSO71,A10VSO100,A10VSO140

9,A10VD: A10VD17,A10VD21,A10VD28,A10VD43,A10VD71

10,A11V: A11V50 A11V90 A11V130,A11V145 A11V160,A11V190,A11V250

11,PVV,PV7: PV2.PVV4.PVV5.PVV21.PVV41.PVV42.PVV51.PVV52.PVV54,PV7-1X,PV7-2X

12,PGF,PGH,PGP: GF1-2X,PGF2-2X,PGF3-3X,PGH2-2X,PGH3-2X,PGH4-2X,PGH5-2X,PGP2-2X,PGP3-3X

13 Others: AP2D21,AP2D25,AP2D36,AP2D38

| Usage | Concrete Mixer |

FAQ

Q:What Is Our Main Application?

A:1.Hydraulic system

2.Agriculture machine

3.Construction machina

4.Automobile

5.Local distributors

Q:What Is The Payment Terms?

A:Full order:30% as desposit, the balance before shipment:

Small order /sample ordre: full payment in advance:

Q:Can I Mark My Own Brand On The Pump?

A:Yes. Full order can mark your brand and code.

Q:What Is Our Main Export Market?

A:Europe (41.7%):Italy,Germany,England,France,Holland,Greece,Spain,Portugal,Swissland,Finland,Czekh,Russia,Poland

Asia(40.5%):China,Korea,Singapore,India,Turkey,Iran,Vietnam,Saudi Arabia,Syria,Isreal,Lebanon

| Application: | Agricultural Machinery, Concrete Mixer |

|---|---|

| Function: | Speed Reduction |

| Layout: | Cycloidal |

| Hardness: | Soft Tooth Surface |

| Installation: | Vertical Type |

| Step: | Single-Step |

| Customization: |

Available

| Customized Request |

|---|

Variations in Cycloidal Gearbox Design

Cycloidal gearboxes come in various designs and configurations to cater to different application requirements. Some common variations include:

- Single-Stage vs. Multi-Stage: Cycloidal gearboxes can be designed as single-stage or multi-stage systems. Single-stage designs offer a lower gear ratio and are suitable for applications with moderate torque requirements. Multi-stage designs provide higher gear ratios and are used for applications demanding higher torque output.

- Input and Output Arrangements: Cycloidal gearboxes can have various input and output arrangements, including coaxial, inline, and right-angle configurations. These arrangements determine the orientation of the input and output shafts relative to each other.

- Size and Torque Capacity: Different sizes of cycloidal gearboxes are available to accommodate a wide range of torque and power requirements. Smaller sizes are suitable for applications where space is limited, while larger sizes handle higher torque loads.

- Mounting Options: Cycloidal gearboxes offer flexibility in mounting options, including base or flange mounting. This allows for easy integration into different types of machinery and equipment.

- Material Selection: Depending on the application’s demands, cycloidal gearboxes can be constructed using various materials, such as steel, aluminum, and alloys. Material selection affects the gearbox’s durability and performance in different environments.

- Backlash Reduction Mechanisms: Some cycloidal gearboxes feature enhanced backlash reduction mechanisms to further improve precision and accuracy in motion control applications.

These variations in design allow cycloidal gearboxes to be tailored to specific application requirements, making them versatile solutions for a wide range of industries and machinery.

Assembling and Disassembling a Cycloidal Gearbox

Assembling and disassembling a cycloidal gearbox requires careful attention to detail and precision. The process can vary depending on the specific design of the gearbox, but the general steps involve:

- Preparation: Gather all the necessary tools, components, and safety equipment for the assembly or disassembly process. Ensure a clean and organized workspace.

- Disassembly: To disassemble a cycloidal gearbox, follow these steps:

- Remove any external components or covers to access the gearbox internals.

- Identify and mark the positions of all components for reassembly.

- Release any locking mechanisms or fasteners that hold the gearbox components together.

- Remove each component carefully, starting from the outermost layers and moving inward.

- Cleaning and Inspection: Clean all components thoroughly using appropriate cleaning agents. Inspect each part for wear, damage, or any signs of degradation. Replace any components that are worn out or damaged.

- Reassembly: To assemble the cycloidal gearbox, follow these steps:

- Begin by assembling the internal components in the reverse order of disassembly.

- Apply lubrication to the gears and other moving parts as recommended by the manufacturer.

- Follow the markings made during disassembly to ensure correct positioning and alignment of components.

- Gradually secure each component with the appropriate fasteners, ensuring proper torque settings.

- Reattach any external covers or components that were removed earlier.

- Testing: After reassembly, perform functional tests to ensure that the gearbox operates smoothly and without any issues. Check for any abnormal noises, vibrations, or irregular movements.

- Final Checks: Double-check all fasteners, connections, and alignments. Verify that the gearbox functions as intended and meets performance specifications.

- Documentation: Keep detailed records of the assembly process, including torque settings, markings, and any adjustments made during reassembly. This documentation will be useful for future maintenance or repairs.

It’s important to note that cycloidal gearboxes can have complex designs, and the exact procedure for assembly and disassembly may vary. Always refer to the manufacturer’s documentation and guidelines for specific instructions related to your gearbox model.

What is a Cycloidal Gearbox?

A cycloidal gearbox, also known as a cycloidal drive, is a type of gearing mechanism that utilizes the principle of cycloidal motion for power transmission. It consists of several components, including a high-speed input shaft, a set of cycloidal pins or rollers, and an outer stationary ring with lobed profiles.

The operation of a cycloidal gearbox involves a unique mechanism:

- Input Shaft: The high-speed input shaft is connected to the driving source, such as an electric motor. It transfers rotational motion to the cycloidal pins.

- Cycloidal Pins or Rollers: These pins or rollers are typically arranged around the input shaft in a circular pattern. As the input shaft rotates, the cycloidal pins also rotate, causing them to engage with the lobes on the outer stationary ring.

- Outer Stationary Ring: The outer ring has lobed profiles, and it remains stationary during operation. The lobes of the outer ring interact with the cycloidal pins or rollers, causing them to move in a unique motion known as epicycloidal or hypocycloidal motion.

The interaction between the cycloidal pins and the lobed profiles of the outer ring results in smooth and controlled motion transmission. The mechanism provides advantages such as high torque capacity, compact size, and precise positioning capabilities.

Cycloidal gearboxes are widely used in various applications, including robotics, automation, packaging machinery, and other industrial systems where high torque, precision, and compact design are essential.

editor by CX 2023-11-30

China Hot selling Weiyou New Excavator Hydraulic Swing Gearbox Part Swing Reducer Rotary Gear Box For CZPT Dh500 with Best Sales

Condition: New

Applicable Industries: Building Material Shops, Machinery Repair Shops, Manufacturing Plant, Popular Cargo Motorcycles Newest High Power Electric Tricycle Three Wheel Trike made in China for Selling Retail, Construction works , Other

Showroom Location: None

Video outgoing-inspection: Not Available

Machinery Test Report: Not Available

Marketing Type: New Product 2571

Warranty: 1 Year, bldc motor factory supply field hay mower brushless motor 18v USA Australia market 1 Year

Application: Replacement

Product name: Ring Gear

Quality: High-Quality

Delivery time: 1-3 Days

Material: Steel

Apply to: Swing Gearbox

Packing: Wooden Case

After-sales service provided: Free replacement

After-sales Service Provided: Free spare parts

Packaging Details: Wooden Case

Port: HuangPu

Products Description TitleSwing Gearbox Used For CZPT DH500 Excavator Swing ReductionApplicable Industries:Manufacturing Plant, Machinery Repair Shops, OtherPlace of Origin:ZheJiang , High Torque Km Series Helical-Hypoid Gearbox From CZPT ChinaGearing Arrangement:Ring GearApplication:ReplacementWarranty:1 yearPacking:Wooden CaseMOQ:1 PieceQuality:High-QualityCustomized support:OEMBrand Name:WeiyouProduct name:Final Drive Motor HousingMaterial:Cast IronPayment:T/T,Master card,Alipay…etc.Delivery time:1 days since getting the payment, Powerful Reducer Gearmotor Motor High Torque Low Speed Worm Gear Self-lock Motor Long Life Metal DC 6-24V 30W 12V 24V IE 2 Brush not the customized itemCompatible Brand:For DOOSAN,other ProcessingCasting Company Profile Certificate Packing&Logistics

Types of Gearboxes

There are several types of gearboxes. Some are known as helical gear reducers, while others are called planetary gearboxes. The article also discusses Continuously Variable Transmission (CVT) and helical gear reducer. If you are interested in purchasing a new gearbox, make sure to read our articles on these different types. If you are confused, consider reading our articles on planetary gearboxes and helical gear reducers.

planetary gearbox

The planetary gearbox has several advantages. Its compact design and light weight allows it to transmit high torques while remaining quiet. The gears are connected to one another through a carrier, which is typically fixed and helps transmit torques to the output shaft. Its planetary structure arrangement also reduces backlash and provides high rigidity, which is important for quick start and stop cycles and rotational direction change. Depending on the design and performance desired, planetary gearboxes are categorized into three main types:

The type of planetary gears used in a given application determines the overall cost of the unit. Manufacturers offer a range of prices, and they can help you determine which gearbox is right for your needs. You should also ask a manufacturer for the cost of a planetary gearbox. By asking about price and specs, you can avoid wasting money and time on a planetary gearbox that does not perform up to its potential.

A planetary gearbox is probably installed in your new car’s automatic transmission. For more information, consult your owner’s manual or call the dealer’s service department. This type of gearbox is more complex than other types of gearboxes, so if you don’t know much about them, do an internet search for “planetary gearbox.”

The teeth of a planetary gearbox are formed by the stepping motion of two gears: the sun gear and the inner ring. The sun gear is the input, while the planetary gears rotate around the sun gear. Their ratio depends on the number of teeth and the space between the planets. If you have a 24 tooth sun gear, the planetary gears’ ratio will be -3/2. The sun gear is also attached to the axle.

Another advantage of a planetary gear system is that it can generate high torques. The load is shared among multiple planet gears. This makes the gears more resilient to damage. A planetary gearbox can be as high as 332,000 Nm, and can be used in vehicles and industrial applications requiring medium to high torque. A planetary gear system is a great alternative to a traditional transmission. So, how does it work?

helical gearbox

The main difference between the helical gearbox and the spur gear is the center distance between the teeth. The helical gearbox has a larger pitch circle than the spur gear and thus requires a radial module. In addition, the two types of gears can only be made with the same tooth-cutting tool as the spur gear. However, the helical gearbox is more efficient in terms of production costs.

The helical gearbox is a low-power consumption, compact type of gearbox that is used for a wide range of industrial applications. They are highly durable and withstand high loads with utmost efficiency. The helical gearbox can be manufactured in cast steel and iron for small and medium units. This type of gearbox is also commonly used for crushers, conveyors, coolers, and other applications that need low power.

The helical gear has many advantages over the spur gear. It produces less noise. It has less friction and is less likely to wear out. It is also quieter than spur gears. This is because multiple teeth are in mesh. Because the teeth are in mesh, the load is distributed over a larger area, resulting in a smoother transition between gears. The reduction in noise and vibration reduces the risk of damaging the gear.

The helical gear’s axial excitation force is obtained using a linearized equation of motion in the rotational direction. The damping coefficient of the equation is 0.07. The helical gear is made up of a steel shaft with a diameter of 20 mm and a 5 mm thick aluminum plate. The stiffness of the bearing is 6.84 x 107 N/m. The damping force of the plate is 2,040 kg/m2/s.

The worm gearbox has a better efficiency ratio than the helical one, but it is less efficient in low-ratio applications. In general, worm gearboxes are more efficient than helical gearboxes, although there are some exceptions to this rule. A helical gearbox is better for applications that require high torque. It may also be more economical in the long run. If you are considering a helical gearbox, consider the advantages it has over worm gearboxes.

helical gear reducer

A helical gear reducer for a machine’s gearbox is an integral component of the drive system. This unit amplifies torque and controls speed and, therefore, compliments the engine by rotating slower than the engine’s input shaft. A helical gear reducer is a compact gearbox component that is used in industrial applications. A variety of sizes is available to suit various machine configurations. The following sections will discuss some of the different types available.

Designed by experts and engineers, a helical gear reducer is a surprisingly small and light gear that satisfies the needs of many machine applications. It features a large transmission torque, a low starting and running speed, and a fine classification of transmission ratios. A helical gear reducer is lightweight and easily connected to other gears, and it features a high technical content.

In order to avoid errors and poor performance, regular maintenance is a must. The proper lubrication of the gear reducer can minimize failures, errors, and poor performance. Every gear reducer manufacturer sells a suitable lubricant, which must match the properties of the machine’s drive mechanism. It is also advisable to check the lubrication regularly to avoid any deterioration of the unit’s performance.

While the worm gearbox may be better for applications where torque is high, the helical gear reducer offers greater efficiency at lower cost. Although worm gearboxes may be cheaper initially, they are less effective at higher ratios. Even if the worm gear is more expensive to buy, it still offers 94% efficiency, which makes it more cost-effective. There are some significant advantages to both types of gearboxes.

The main advantage of a helical gear reducer over a spur gear is its smoother operation. Unlike spur gears, which have teeth that are straight, helical gears have angled teeth that gradually engage with each other. This helps ensure that the gear does not grind or make excessive noise when it turns. Additionally, they are less commonly used in automation and precision machinery. They are often used in industrial applications.

Continuously variable transmission

A Continuously Variable Transmission (CVT) is an automatic transmission that can run through a vast number of gears. Unlike a standard automatic transmission, it can run at any speed, even at a low rev. The CVT is also capable of running at infinitely low gears. Its basic function is to provide different torque ratios to the engine. In addition to delivering power, CVTs have other benefits.

One of the major advantages of a CVT is its simplicity. Its simplicity translates into fewer moving parts, which means less maintenance. The CVT’s simplicity also means that it can handle a wide variety of different types of road conditions and driving styles. In addition to being a great alternative to a traditional automatic transmission, CVTs can be used on many other types of vehicles, including tractors, snowmobiles, motor scooters, and power tools.

A CVT is much smoother than a conventional automatic transmission. It never has to hunt for a gear. It also responds well to throttle inputs and speed changes. Both of these technologies are available on many modern vehicles, including the Nissan Rogue and Mazda CX-5. It’s important to note that each of these transmissions has its pros and cons. So, if you’re looking for a car with a CVT, make sure to read the reviews. They’ll help you decide which transmission is right for you.

Another advantage of a CVT is its fuel efficiency. Many cars now feature CVTs, and they’re becoming increasingly popular with automakers. In addition to fuel efficiency, most cars with CVTs also have a smoother ride. There’s no more sudden downshifts or gear hunting. This makes driving a lot easier. And, the added benefits of smoother driving make CVTs the ideal choice for many drivers.

Although a CVT is more common among Japanese car manufacturers, you’ll find CVTs on European car models as well. The Mercedes-Benz A-Class, B-Class, and Megane are some examples of vehicles that use this technology. Before making a decision, consider the reliability of the model in question. Consumer Reports is a good resource for this. It also offers a history of use and reliability for every type of car, including the Honda Accord.

China manufacturer Newstart Low Loss Reduce Buzz Noise Inductor Single Screw Hydraulic Planetary Gearbox 201 For Extruder Machine with Great quality

Warranty: 1 years

Applicable Industries: Manufacturing Plant, Machinery Repair Shops, Other

Weight (KG): 19 KG

Customized support: OEM

Gearing Arrangement: Planetary

Output Torque: as customer requirements

Input Speed: as customer requirements

Output Speed: as customer requirements

Product name: Planetary Gearbox

Keywords: Planetary Gearbox Precision

Application: Textile,Machinery,Power Tranmission,Packing Machine, Hot Sale Cast Iron Single Wheel Pulley with Swivel CNC…

Material: 20CrMnTi, 40Cr, 42CrMo…

Structures: Coupling, Bearing + Gear + Box…

Ratio: 3-1000 or as customer requirements

Packing: Carton or as customer requirements

Packaging Details: Carton or as customer requirements

Port: China, HangZhou

Specification Product Nameplanetary gearboxBrand NameNEWSTARTApplicable IndustriesServo MotorGearing ArrangementPlanetaryRatio i3,4, Factory direct sale high precision custom timing belt pulleys with keyway 5,6,7,8,10Input interfaceAccording to motor outputMax. radial load (N)9600Max. axial load (N)4800Rated input speed (r/min)2000Max. input speed (r/min)4000Noise (db)≤63Backlash – GTM Gearbox Rotary Mower Gearbox Transmission Gearbox For Tractor PTO Class P2 (arcmin)≤5No-load torque at 20oC (Nm)≤0.1Operating temperature (℃)-15 to +90Service life (h)≥20,000Protection grade (IP)IP54MOQ1 More Products Company Profile Semi-Automatic PET Bottle Blowing Machine Bottle Making Machine Bottle Moulding MachinePET Bottle Making Machine is suitable for producing PET plastic containers and bottles in all shapes. Exhibition Certifications FAQ Q: Are you a manufacturer or a trader? A: We are a professional factory with 16 years of production experience. Q: Are all motor types compatible with planetary reducers? A: Our planetary gear reducers are customized according to your motor mounting flange, all types of motors can be matched. Q: What is the warranty period of the product? A: The warranty period of the product is 18 months. Q: What is the delivery cycle of the product? A: The delivery time of general products is 20-25 days. Customized products in about 45 days. Please ask for specific delivery time before ordering. If you have other questions that are not clear, High quality MB000083 Center Bearing for CZPT CANTER MB000076 MB006207 12019-25403 MC86~13 0571 88828 1385811777816 you are welcome to contact us.

The Different Types of Gearboxes

There are many different types of gearboxes. Some brands have more than one type. In this article, we’ll discuss the planetary gearbox, the worm reduction gearbox, the shaft mounted gearbox, and the one speed gearbox. This article will also help you determine which type of gearbox is best for your vehicle. And don’t worry if you don’t know the terminology yet. We’ll explain each type in detail so that you know what you’re getting yourself into.

Planetary gearbox

Planetary gears have many advantages. The multiple gears in a planetary gearbox mesh simultaneously during operation. As such, they provide high efficiency and transmit high transmittable torque. These gears are widely used in various industries and are resistant to high shock loads and demanding conditions. CZPT is one of the companies that offer planetary gearboxes. Its products do not require special tools for assembly, and its scalable design minimizes safety stock.

Among the numerous benefits of planetary gearing is its compactness and lightweight. As such, it is suitable for wide applications with space and weight constraints. However, to truly appreciate its benefits, it is necessary to understand its mechanisms. Here are some of the most common details about planetary gearing:

The planetary gearbox has two mounted gears: an input shaft and an output shaft. Each gear has multiple teeth that are attached to a carrier and rotate with the input shaft. The carrier is connected to the output shaft. A planetary gear is mounted on both gears via a carrier. The carrier rotates in order to drive the planetary gear. The sun gear is often the input gear. The other gear is called the outer gear.

Planetary gearboxes are highly customizable. The size, mounting, and housing options vary, as do the reduction ratios and input speeds. Different types can be manufactured for different applications and include options such as electrical or mechanical preload. The final design of a planetary gearbox can be highly customized, based on the specifications of the application. By combining engineering excellence and ongoing innovation, planetary gearboxes provide years of trouble-free operation.

A planetary gearbox can be either an electric motor or a manual one. The latter has more features than the former, and can be used in applications where space is an issue. The primary features of a planetary gearbox include its backlash, torque, and ratio. Secondary features include noise, corrosion resistance, and construction. A planetary gearbox is a highly versatile gearbox that can drive anything from simple machinery to advanced electrical systems.

Worm reduction gearbox

The global worm reduction gearbox market report compiles key insights from the industry to help you improve your business strategy. This report will help you create a comprehensive business document that will enhance your company’s competitive edge. To obtain this report, visit our website now! Read our latest report to find out what you can expect from the global worm reduction gearbox market. Alternatively, request a sample copy for more details. Here is a sneak peek of the report:

Worm gears are made with different thread counts and are usually not matched with the CZPT standard. In general, a single thread worm should be used with a single thread worm. Worm gears have either right or left threads, and their thread count will be different as well. This type of gear is used to reduce the speed of a rotating shaft. The speed reduction ratio will be about 50 percent if the worms have the same thread count as the CZPT gears.

The standard gear set transfers power at the peak load point of a tooth, called the pitchline. The worm gear moves slowly against the wheel’s metal surface. The worm gear is also more complex than the standard gear because the worm is sliding rather than rolling. Worm gears are hard to lubricate. Moreover, the sliding contact between the gear and worm increases the complexity of the gear set. They can be a great solution for applications where noise is a significant factor.

The axial pitch and circular pitch of the worm are equal. The ratio of these two indices determines the speed of transmission. For a worm reduction gearbox to work, the axial pitch and the circular pitch must match. The pitch angle of a worm can either be left-handed or right-handed. The lead of a worm is the distance one thread travels in one revolution. The lead angle is the angle tangent to the thread helix of the cylinder’s pitch. When a worm mesh is reversed, the majority of the mesh will be on the receding arc.

Worm gears generate more heat than their counterparts, so it is important to choose a worm reduction gearbox carefully. You will want to choose the material and amount of lubricating oil carefully. Worm gears are generally made of tin bronze. The paired worms are hardened to HRC45-55. In general, they are durable, lasting up to ten years. But they will wear out – and they wear out – so you may want to consider some other factors.

Shaft-mounted gearbox

Shaft-mounted gearboxes are designed for a variety of mining and quarry applications. Their high reliability and low maintenance make them an excellent choice in these types of applications. Shaft-mounted gearboxes also feature an optional backstop device that prevents the unit from rotating in one direction. This makes them an excellent choice for applications where alignment accuracy is an issue. Here are some of the benefits of using a shaft-mounted gearbox:

Shaft-mounted gearboxes are typically constructed of aluminium, and come in sizes ranging from 050 to 125. They feature a variety of reduction ratios and ensure optimum efficiency in all operating conditions. New S series sizes, 140 and 150, extend the application range of shaft-mounted gearmotors. They are both backed by a two-year warranty. For even greater peace of mind, Shaft-mounted gearboxes are available with a range of warranty options.

The most common applications for a Shaft-mounted gearbox include traction-driven applications where a low-speed shaft is required for operation. They also are suitable for applications without a foundation, where the motor is mounted next to the reducer. To prevent the gear drive from rotating, a torque arm is attached between the motor and the shaft. Small-sized shaft-mounted gear drives are usually made without motor mount kits, which can make them an excellent choice for conveying light loads.

Another important feature of a Shaft-mounted gearbox is its mounting position. The reduced motion through the drive is redirected through the shaft, creating additional forces. These additional forces can affect the performance of the gearbox, causing vibrations and noise. Consequently, it is important to replace worn or damaged belts on a regular basis. Further, shaft-mounted gearboxes can be affected by problems with other components and amplify vibrations.

1 speed gearbox

CZPT Group Components produces one speed gearboxes. These transmissions are produced in the CZPT Group’s Kassel plant. They are compact and robust, and are designed for easy integration. The Bosch Rexroth GD1 one-speed gearbox is easy to install horizontally or vertically. The Plug and Drive system integrates the gearbox with the existing cooling system. There are many other benefits to this gearbox.

With an ID.3 electric drive motor, the maximum torque is delivered at 16,000 rpm. This single-speed transmission offers high power density and excellent noise-reduction, making it ideal for electric vehicles. The e-drive motor is extremely quiet and requires precision manufacturing. The e-drive motor also enables a wide range of driving conditions. It can reverse when needed, and reaches its maximum speed at 16,000.

The single-speed gearbox is a standard feature on most electric vehicles. Some electric vehicles, such as the Porsche Taycan, will be equipped with a two-speed gearbox. This gearbox offers more top speed and range, but it is more complex than a standard single-speed gearbox. CZPT doesn’t need to add complexity to its electric vehicles. After all, a 355 horsepower family wagon is not likely to need a dual-speed gearbox.

In addition to simplifying the transmission, the patent claims also address improvements in structural design. Fig. 5 shows a schematic representation of a transmission 50′, wherein gear sets Z1 and Z4 are exchanged between partial transmissions. This switch matrix also reflects the synchronized gears and lastshelf gears. Hydraulically betatigte Lamellenkupplungen (HBA) also form a last-shelf gear.

Another advantage of the patent claim is that it offers numerous functional freedoms, which is especially valuable in the design of an automobile. One of the patent claims identifies a tosatzlicher middle gear that allows a driver to switch between second and third gears, with a single gearbox. In a conventional one-speed transmission, the tosatzlicher middle gear is attached to the second and first part gearbox. The latter has a second and third gear.

China factory 80000 Nm hydraulic motor DX80 speed reducer gearbox reduce speed near me factory

Warranty: 1 year

Applicable Industries: Manufacturing Plant, Machinery Repair Shops, Retail, Construction works , Energy & Mining, Construction Machinery, Excavators, Cranes

Customized support: OEM, ODM, OBM

Gearing Arrangement: Planetary

Output Torque: 80000 Nm

Input Speed: 1947 r/min

Output Speed: 10.5 r/min

Model number: DX80

Name: reducer

Usage: travel drive reducer

Max. output torque: 80000 Nm

Ratio: 185:1 or Customer require

Input Form: Hydraulic Motor

Gears Style: planetary gears

Application: wheel and crawler cranes, excavators, CZPT high strength factory supply 880tab conveyor chain with roller etc

Customization: acceptable

Mounting Position: customer require

Certification: ISO

Packaging Details: Wooden box

Port: HangZhou

80000 Nm hydraulic motor DX80 speed reducer gearbox reduce speed Product Overview Product Name ReducerModelDX80Usagetravel drive reducerMax. output torque80000 NmRatio185:1 or Customer requireInput FormHydraulic MotorGears Styleplanetary gearsApplicationwheel and crawler cranes, excavators, etcCustomizationacceptableMounting Positioncustomer require Main Features 1) Compact size2) Low noise3) High transmission efficiency4) Good working condition under lower speed5) Customized hydraulic motors and brakes for different request6) One Year Warranty from reception7) Free components for replacement within warranty period8) Professional and tailored solution for different requirements9) Free technical support at any time10) Customer training is available. Company Profile ZheJiang CZPT Intelligent Technology Co., Ltd is a scientific and technological enterprise engaged in the research, development and production of planetary gear transmission products, like walking reducers, swing reducers, lifting reducers, hydraulic planetary winches, etc. The company has always put quality management as the top priority of the company’s development. The planetary gear transmission productions are manufactured not only meet the international ISO 4301 and ISO9001 standards, wp worm screw jack parts gearbox reducer worm actuator 130 ratio worm gear reduction motor drive gearmotor speed reducer but also meet the US SAE J706 and the European Union CE standards. Daixin Intelligent Technology relies on quality, reputation and service to develop, cultivate and consolidate the national and global markets. Be our partners, be our friends. Recommend Products Product packaging Packing and shipping1. Packed by wooden box, fumigation-free for export and import standard.2. Shipped by sea or air with customer require FAQ 1.How to choose the gearbox which meets our requirement?A)Look through our shop, find a proper item, send me an inquiry, I quote details for you.B)In case no suitable item in our shop, send me an inquiry with your requirements, we can customize for you.2.How to get a good quotation?To offer a precise price, please send me purchasing quantity. Different quantity, Driveshaft Flex Disc Fit for GM Holden Chevrolet Commodore VX- VZ inc Lumina Caprice Year 2000-2006 92143598 92148358 different packing size and weight, then different exporting cost.3.What is payment term?A)For regular design: 30% deposit, the balance before loading. B)For customized design: 50% deposit, the balance before loading. The longer cooperation, the better payment term.4.How to ship?Different methods are acceptable: EXW, FOB, CFR, CIF, DDU. We follow your convenience.5.How about after-sale service?A)Within warranty, all spare parts are delivered for free. B)Exceed warranty, all spare parts are offered with the lowest production cost.Warranty period is 1 year, Plastic strain relief bushing but our servicing is for the whole lifetime of product, so no worry for reselling and personal resell.

Types of Gearboxes Used in Wind Turbines

Many manufacturers of wind turbines have chosen different solutions for the drive train of the turbines. Most prefer gearboxes because of their durability. These have several design features that make them well suited to shocks, stresses and wear. Regardless of the type of gearbox used, continuous maintenance and monitoring can extend the lifespan of these machines. Performing these tasks regularly can help detect and resolve any problems before they become serious. Here are some of the problems associated with gearboxes.

Coaxial helical gearbox

The R series helical inline gearbox is a high-quality speed reducer for heavy-duty industrial applications. These units are designed with increased power density in mind and are equipped with various cooling options. High-grade seals and lubricants help to increase efficiency and minimize thermal loading. They are ATEX-compliant. Their reversible modules are an excellent choice for high-speed applications, such as compressors, compressor blowers, and pumps.

The normal module set of helical gearbox is manufactured using the same tooth-cutting techniques as spur gears. This allows the production of higher-quality, more economical, and more compact helical gears. Although the performance of helical gears is lower than spur gears, they are durable and capable of transferring motion and power between two shafts. And because they are able to handle a much greater load, they are preferred for heavy-duty applications.

The main tooth form of a helical gearbox presents fixed velocity ratios, even if the center gap is not completely set. This requirement is sometimes referred to as the fundamental rule of gearing. A helical gearbox is similar to a set of paper spur gears, with the exception that the sections must stagger in opposite directions. There are two kinds of helical gears for parallel shafts: left-handed and right-handed.

The Industrial Gearbox market is segmented based on product type, application, and geography. The report analyzes the competitive scenario by segmenting the market by region, company, and type. Using this information, it estimates market size, revenue, and consumption. The report also features key information about COVID-19 and its impact on the overall industry. And it also provides a competitive landscape with industry-leading players.

Industrial gearboxes are integrated with devices and make automation processes more efficient and reliable. Increasing labor costs, shortage of skilled labor, and the ageing workforce are driving the demand for automation technologies. The industry requires newer and more advanced models and technologies to compete in the global market. You can use Coaxial helical gearbox in a variety of applications. Its benefits are endless. If you are looking for a reliable, high-performance industrial gearbox, CZPT can help you find it.

Worm reduction gearbox

As a general rule, larger center distance worm reduction gearboxes are more efficient than smaller ones. Worm gearboxes with 2.6-in. center distances start to lose efficiency as their ratios increase. Larger center distances tend to have higher efficiency than smaller ones. However, this difference may not always be enough to justify the higher investment. Worm gear reducers typically cost less than equivalent helical units.

The use of aluminum for worm reduction gearboxes is a popular choice for those involved in the manufacturing of Packaging Equipment. In addition to being lightweight, aluminum worm reduction gearboxes have high strength and rigidity. Manufacturers recommend this choice because of its high rigidity and durability. While purchasing aluminum worm reduction gearboxes, keep in mind that they are more expensive than steel versions. However, they have a longer lifespan and are highly resistant to wear.

The worm’s helix angle is larger than a helical gear, which allows a much higher gear ratio. In addition, the worm’s body is usually longer in the axial direction than helical gears. Worm reduction gears are often left-handed, and British or Indian standards are usually followed. The worm wheel is made of hardened alloy steel PB2-C, while the gearbox case is made of hardened alloy steel FG 220 or FG 250res.

The worms in a sacrificial system are relatively safe from wear. Instead, the softer wheel is the cause of most wear and tear. The oil analysis report for a sacrificial system shows low iron levels and high copper concentrations. However, if a worm reduction gearbox has a bad reputation, you should consider purchasing a new one. If the worm gears are in good condition, the gearbox is still a viable option for a new or replacement vehicle.

The advantages of a worm reduction gearbox are numerous. The worm gearbox is widely used in industrial settings, where it provides torque and speed reduction to move products. Worm gearboxes are also commonly used in automatic security gates, which will not run in reverse. Most security gates use two separate worm drives to keep the gate in the closed position. There are also many other uses for worm reducers. You can learn more about the benefits of worm gearboxes by reading below.

Stainless steel gearbox

Stainless steel gearboxes offer a number of advantages over standard gearboxes. They match the existing stainless motor design and cost 50 percent more on average. They have stainless output shafts and housings as well as corrosion resistant hardware and a food grade lubricant. Stainless steel gearboxes feature IP 65 sealing, Viton shaft seals at the input and output shafts, and a Buna o-ring between the housings. Stainless steel gearboxes also eliminate flat surfaces and allow for a cylindrical design.

Stainless steel gearboxes are more durable than traditional cast iron or epoxy-painted gearboxes. These gearboxes can withstand repeated washdown operations without damage. They also do not collect particles or bacteria. And because stainless steel does not corrode, stainless steel gearboxes can withstand harsh environments, such as oily or greasy environments. Because stainless steel gearboxes are corrosion-resistant, they require little maintenance. They are also easier to clean and maintain, resulting in fewer replacements and a longer life span for your gearbox.

Stainless steel gearboxes are a great choice for food and other industries that require high hygiene standards. In addition to its durability, stainless steel gearboxes are ideal for applications in environments that require high levels of humidity and water. They are also life-lubricated, and they can be supplied with food-grade oils or water. The CZPT Gears stainless gearbox is a versatile option for a variety of applications.

Stainless steel gearboxes offer superior corrosion protection and can withstand harsh environments. The stainless steel cover, housing, and external hardware ensure superior corrosion protection. If you have questions about the varying benefits of stainless steel gearboxes, contact a CZPT Gear sales representative to learn more about your options. And if you are not sure which type is right for your needs, contact a CZPT Gear sales representative to find the perfect solution for your business.

1 speed gearbox

Volkswagen Group Components manufactures the one speed gearbox. The gearbox has a high-performance electric drive motor that produces 310 Nm of torque over a wide speed range. Designed for maximum range, this gearbox uses a single gear for all driving situations. It is extremely quiet, too, and requires precision manufacturing. Volkswagen has also made it available in a reverse-gear configuration with power electronics. Volkswagen’s ID.3 EV’s e-drive motor is a perfect example of this.

The first part of the transmission corresponds to the even and odd gears, while the second part has the straighter gears. A single gear set can change between both modes. An intermediate gear set is also possible. A lastshelf gear can be formed by hydraulically betigte Lamellenkupplungen. Both types of gears can be exchanged between partial transmissions. The invention may furthermore include a transmission with the same gear ratios as the first part of the transmission.

Another variation of the one speed gearbox is the CVT. This type of gearbox has only one drive unit, which means it does not require a clutch or brake. Its power is derived from the torque generated by the Internal Combustion Engine at a particular speed. The engine cannot sustain such high torque levels above 5500 RPM, which will reduce the MPG. Also, raising the RPM will reduce the acceleration, and in severe cases may lead to an engine crash.

As the number of applications for a 1 speed gearbox increases, its design and functionality will continue to evolve. Bosch Rexroth has developed its eGFZ gearbox based on customer feedback. They are currently working on various pilot projects and hope to put it into production in the next few years. However, if you want to buy a 1 speed gearbox now, consider the benefits of a first-rate design.

in As-Suways Egypt sales price shop near me near me shop factory supplier Sgr Brand Inline Straight Planetary Gear Speed Reducer, Gearmotor, Gearboxes Coupled with ABB Hydraulic Motor manufacturer best Cost Custom Cheap wholesaler

More importantly, we make particular components according to supplied drawings/samples and warmly welcome OEM inquiries. Our items are utilized in a lot of fields. we have obtained the have confidence in of buyers around the world. Product Description

SGR planetary EPT motor

EPT data:

one. Ratio selection: 8.1-191

two. Enter EPT: .twelve-270 KW

3. Permit torque rang: le 50000 N. M

4. Output velocity: .three~205 r/min

5. Structure: Foot-mounted, flange-mounted, shaft-mounted

| Input structure | motor,IEC flange |

| Output velocity | strong shaft, hollow shaft with important,with shrink disk |

Characteristic:

1. Adopt optimized design and style, module mix, rigEPT angle output, area reduction

2. Substantial energy and EPTevity EPTs

3. Can be combined with various motors, wiEPTratio assortment

four. Large output torque, efficiently startup, substantial effectiveness

Production images:

EPT Photos :

Manufacturing facility

———————————————————————————————————————————————

FAQ:

one.Are you a manufacturing facility or traEPT?

We are a specialist manufacturing facility which has twenty a long time history EPTized in EPT EPT .

two.MOQ:

Our MOQ is 1pcs. Nevertheless there is one dealing with EPT $150 for the one orEPTwhich much less than $3000.00

3. Warranty

Our warranty is 12months

four. Payment phrase

one hundred% T/T EPT and LC at sigEPT .

five. Do you settle for customization ?

Of course.SGR have sturdy R ampD crew, we can supply customizable service in accordance to demands.

6. EPT

EPTly we use stXiHu (West Lake) Dis.Hu (West Lake) Dis.rd export plywood circumstance to arrange the shipment .

seven. Shipping and delivery time

In regular ,time of shipping and delivery is 30daEPTafter obtaining the prepayment .

eight. What varieties of certification do you use ?

DNV-ISO9001:2008, SGS,CE and so forth, And new merchandise patent.

9. What types of inspection you do prior to cargo ?

We do temperature take a look at, noise, and oil leak inspection and commissioning before shipment.

ten.How do you solve if the production have issue ?

Primarily, we don’t require client deliver the merchandise back to us. Simply because the EPT is quite higher, if there satisfies a problem,we to begin with question for the photos for destroyed elements. And foundation on the photos, we can have a fundamental notion for the defect explanation. Our guarantee is twelve months, if throughout the promise, we can source repair .

China manufacturer & factory supplier for china in Kottayam India supplier parker hydraulic motorBmh hydraulic motorhydraulic motors With high quality best price & service

EPG is a major provider of large good quality, cost-efficient electrical power transmission elements. As our item strains carry on to broaden to meet our customer’s wants, our dedication to personalised consumer provider and on-timThese are compact, hefty-responsibility drives that offer you lengthy-life performance characteristics and simplified servicing. They include double and triple reduction units. They are available in a variety of configurations for maximum positioning flexibility. They supply excellent strength and longevity. The higher strength output shaft assures ability for large torque and overhung hundreds.e shipping and delivery continues to be 2nd to none.Due to our sincerity in giving ideal support to our clientele, knowing of your wants and overriding sense of obligation toward filling purchasing needs,a specialised provider of a full variety of chains, sprockets, gears, equipment racks, V-belts, couplings and reducers, pto shaft, agricultural gearboxes….

Overview

Quick Specifics

- Right after Guarantee Provider:

-

Video technical assist

- Local Service Location:

-

Egypt

- Showroom Spot:

-

Egypt

- Variety:

-

parts

- Right after-income Provider Offered:

-

Video clip specialized support

Offer Potential

- Supply Capacity:

- 500000 Piece/Items for every 12 months

Packaging & Supply

- Packaging Details

- Carton or Plywood case

- Port

- NINGBO/SHANGHAI, CHINA

-

Guide Time

: -

Amount(Luggage) 1 – 50 >50 EPG Machinery is positioned in XiHu Area HangZhou Zhejiang ,China. It is 30km from our factory to HangZhou worldwide airport.

Est. Time(times) fifteen To be negotiated

Online Customization

BMH Technological Knowledge

| TYPE | BMH-200 | BMH-250 | BMH-315 | BMH-four hundred | BMH-500 | |

| Displacement(ml/r) | 203 | 253.7 | 318.9 | 405.9 | 471.one | |

| Max.Stress.Drop(Mpa) | cont. | sixteen | sixteen | fifteen | fourteen | twelve |

| int. | 19 | 19 | eighteen | 17 | fifteen | |

| peMaintenance Upkeep on these units is straight ahead and like all shifting parts these require their fair share of grease and must be greased often as these components perform really hard and are subject matter to all that mother nature can provide for use and tear. Excellent grease is crucial here set grease in until finally you see the outdated grease oozing out. Go straightforward on the “U” joints so you do not blow the seals. Short bursts of a reduced pressured air grease gun or even better a hand pump gun will do the job and must be completed based mostly on hourly use. At minimum as soon as a time the major and secondary shafts need to be separated. All debris and any rust must be cleaned off. Examine completely for any signs of tension and utilize a liberal volume of grease. In addition to this, equally the PTO yoke holes need to have grease inside of them at least once a calendar year along with the yoke lock pin.ak. | 22 | 22 | 21 | 20 | eighteen | |

| Max.torque(N.m) | cont. | 425 | 530 | 610 | 825 | 720 |

| int. | 510 | 635 | 750 | 900 | 910 | |

| peak. | 590 | 735 | 875 | 1055 | 1090 | |

| Max. Speed (cont.)(r/min) |

365 | 295 | 235 | a hundred and eighty | one hundred fifty five | |

| Max.Circulation(cont.)(L/mim) | seventy five | 75 | seventy five | 75 | seventy five | |

| Max.Output.Power(cont.)(Kw) | 13.8 | thirteen.eight | twelve.5 | eleven.five | 9.8 | |

| Weight(Kg) | 10.5 | 11 | eleven.five | twelve.5 | thirteen | |

Intermittent procedure the permissible values could arise for max.10% of every single moment

Peak load:the permissible values might happen for max.1% of each and every moment

Best China manufacturer & factory china in Yaounde Cameroon supplier Poclain motorhydraulic wheel loader with hydraulic transmissionhydraulic motor ms18 mse18 With high quality best price

It has established stable cooperation with many well known universities and institutes in china such as, Zhejiang University, Jilin University, Technical committee of national chain drive standard, Institute of national chain drive, Zhejiang application engineering material institute, Huhan material protection institute; and it cooperated to found China First Car chain institute with National chain drive institute. The shaft surface under the oil seal lip is critical to effective sealing. Any lead remaining from the turning process acts like an oil pump and causes leaks. While plunge grinding is the most common method for finishing seal journals, the process does not guarantee acceptable surfaces.

Overview

Quick Details

- After Warranty Service:

-

Video technical support

- Local Service Location:

-

Egypt

- Showroom Location:

-

Egypt

- Type:

-

parts

- After-saleEPG brand rotocultivator ploughshares in T. line were selected as the Nationwide Rotary Tillage Machinery Industry “Perfect Brand Products” in 2007 by Rotocultivator Branch of China Agricultural Machinery Industry Association. s Service Provided:

-

Video technical support

Supply Ability

- Supply Ability:

- 3000 Piece/Pieces per Month

Packaging & Delivery

- Packaging Details

- packaged in plywood case or PALLET

- Port

- NINGBO/SHANGHAI, CHINA

-

Lead Time

: -

Quantity(Bags) 1 – 20 Once the PTO has begun to power the attachment, steadily increase the throttle until you reach the operating speed. The typical running RPM (revolutions per minute) for a tractor mounted PTO is 540 RPM, although there are tractor models that rev higher. Always refer to your particular tractor model for instructions prior to first-time use.

>20 Est. Time(days) 15 To be negotiated

Online Customization

| TYPE |

Displacement (ml/r) |

Pressure (Mpa) |

Torque (N.M) |

Speed range |

Max Cont Power |

|||

|

Single Speed |

Double Speed |

Peak pressure |

Cont Pressure |

Rate torque |

Theoric torque |

|||

| TMS83-6700 | 6679 | 3340 | 35 | 25 | 25258 | 1010 | 0-65 | 123 |

| TMS83-8300 | 8328 | 4164 | 35 | 25 | 31495 | 1259 | 0-50 | 123 |

| TMS83-10000 | 10019 | 5010 | 35 | 25 | 37890 | 1515 | 0-40 | 123 |

| TYPE |

Displacement (ml/r) |

Pressure (Mpa) |

Torque (N.M) |

Speed range |

Max Cont Power |

|||

|

Single Speed |

Double Speed |

Peak pressure |

Cont Pressure |

Rate torque |

Theoric torque |

|||

| TMS125-10000 | 10000 | 5000 | 30 | 25 | 37818 | 1512 | 0-50 | 150 |

| TMS125-12500 | 12500 | 6250 | 30 | 25 | 47273 | 1890 | 0-40 | 150 |

| TMS125-15000 | 15000 | 7500 | 30 | 25 | 56727 | 2269 | 0-30 | 150 |

Best China manufacturer & factory Chinese supplier Eaton geroler rail hydraulic motor hydraulic motor with brake motor rail hydraulic motor hydraulic With high quality best price

We are looking forward to developing successful business relationships with new clients around the world in the future.

Overview

Quick Details

- Condition:

-

New

- Warranty:

-

1.5 years

- After Warranty Service:

-

Online support

- Local Service Location:

-

none

Girard DYN range-2 Our range of worm gearboxes is particularly suited to demanding stepper and servo motor applications.

- Showroom Location:

-

none

- Type:

-

parts

- Brand Name:

-

OEM

- Place of Origin:Zhejiang, China

- Pressure:

-

–

- Structure:

-

–

- Certification:

-

–

- Weight:

-

–

- Power(W):

-

–

- Dimension(L*W*H):

-

–

Adhering to “Survival by Quality, Development by Technology & Credit”, The company will constantly improve product performance to meet the increasing customer requirements in the rigorous style of work.

- After-sales Service Provided:

-

Video technical support

- Color:

-

Silver

Supply Ability

- Supply Ability:

- 500000 Piece/Pieces per Year

Packaging & Delivery

- Packaging Details

- Carton or Plywood case

- Port

- NINGBO/SHANGHAI, CHINA

-

Lead Time

: -

Quantity(Bags) 1 – 50 >50 Est. Time(days) 15 To be negotiated

Online Customization

The PTO shaft is the mechanical device that transfer the power from the tractor to the agricultural implement. The PTO shaft is made of two joints connected by telescopic tubes: one joint connects the outer tube of the PTO shaft with the tractor power take-off , the other joint connects the inner tube of the PTO shaft with the implement. The range of the EPG GROUP PTO shafts includes 9 sizes of different dimensions according to the power to be transferred . The sizes of the EPG GROUP PTO shafts and the power that can be transferred at 540 rpm are : SIZE 1 up to 16HP SIZE 2 up to 21HP SIZE 3 up to 30 HP SIZE 4 up to 35HP SIZE 5 up to 47HP SIZE 6 up to 60HP SIZE 7 up to 70HP SIZE 8 up to 90HP SIZE10 up to 110HP

TECHNICAL DATA

| TYPE | BMP-50 BMPH-50 |

BMP-80 BMPH-80 |

BMP-100 BMPH-100 |

BMP-125 BMPH-125 |

BMP-160 BMPH-160 |

BMP-200 BMPH-200 |

BMP-250 BMPH-250 |

BMP-315 BMPH-315 |

BMP-400 BMPH-400 |

|

| Displcement (ml/r) |

52.9 | 79.3 | 98.2 | 120.9 | 158.7 | 196.4 | 241.8 | 317.3 | 392.9 | |

| Max.Pressure. Drop (Mpa) |

cont. | 14 | 14 | 14 | 14 | 14 | 14 | 12 | 10 | 8 |

| int. | 17.5 | 17.5 | 17.5 | 17.5 | 17.5 | 17.5 | 14 | 12 | 10 | |

| peak. | 22 | 22 | 22 | 22 | 22 | 22 | 20 | 15 | 13 | |

| Max. torque (N.Mm) |

cont. | 97 | 148 | 183 | 229 | 295 | 364 | 369 | 404 | 416 |

| int. | 125 | 189 | 238 | 292 | 382 | 470 | 444 | 501 | 531 | |

| peak. | 149 | 222 | 276 | 340 | 445 | 532 | 568 | 555 | 596 | |

| Max. Speed (cont.)(r/min) |

755 | 750 | 610 | 490 | 375 | 305 | 245 | 185 | 150 | |

| Max. Flow (cont.)(L/min) |

40 | 60 | 60 | 60 | 60 | 60 | 60 | 60 | 60 | |

| Max. Output. Power (cont.)(Kw) |

6.5 | 10 | 10 | 10 | 10 | 10 | 8 | 7 | 5.7 | |

| Weight(kg) | 5.6 | 5.7 | 5.9 | 6 | 6.2 | 6.4 | 6.6 | 6.9 | 7.4 | |

Intermittent operation the permssible values may occur for max. 10% of every minute

Peak load: the permissible values may occur for max.1% of every minute

Best China manufacturer & factory china supplier Hydraulic WinchWinchtruck hydraulic winch With high quality best price

With many years’ experience in these lines, we have been distinguished from other suppliers in China by our advantages in competitive pricing, on-time delivery, prompt responses, on-hand engineering support and good after-sales services.

Overview

Quick Details

- After Warranty Service:

-

Video technical support

- Local Service Location:

-

Egypt

If you’re looking for a 540 PTO shaft, 540 to 1000 PTO adapter, 540 PTO hydraulic pump, or a 540 PTO gearbox, look no further. It’s important to replace PTO parts that are worn or cracking before you have a major breakdown that could be expensive and even dangerous. We have PTO drive shafts as well as essential shield parts for your safety. Our Eurocardan parts include a range of types of clutches to improve the operation of your power take-off system. PTO shafts and accessories are an important part of the more than 26,000 items we carry for farm, shop, home and garden.

- Showroom Location:

-

Egypt

- Type:

-

parts

- After-sales Service Provided:

-

Video technical support

Supply Ability

- Supply Ability:

- 3000 Piece/Pieces per Month

Packaging & Delivery

- Packaging Details

- packaged in plywood case or PALLET

- Port

- NINGBO/SHANGHAI, CHINA

-

Lead Time

: -

Quantity(Bags) 1 – 50 >50 Est. Time(days) 15 To be negotiated

Online Customization

With its other features, as NITRILE-BUTADIENE rubber ring seals ñ according to DIN 3760 regulation -, high quality bearings, and an aluminium finish, this product is the best choice within this productís family in the gears market.

![]()

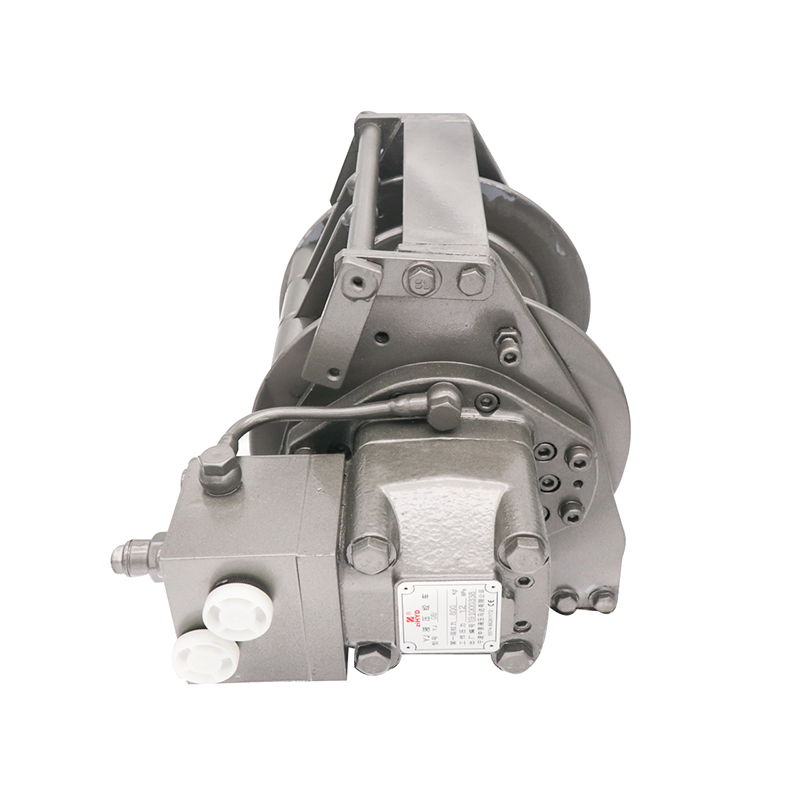

1.Hydraulic Winch is made up of inner BM orbit hydraulic motor, planet gearbox decelerator, mechanism brake, ect.

2. Hydraulic Winch adopts steel structure’s machine frame using thread conjuction, the control system of which includes shuttle valve and balance valve,ect. Having compact design and small size.

3. Hydraulic Winch adapts to lifing and traction facilities, such as shipping, port, car, ect.

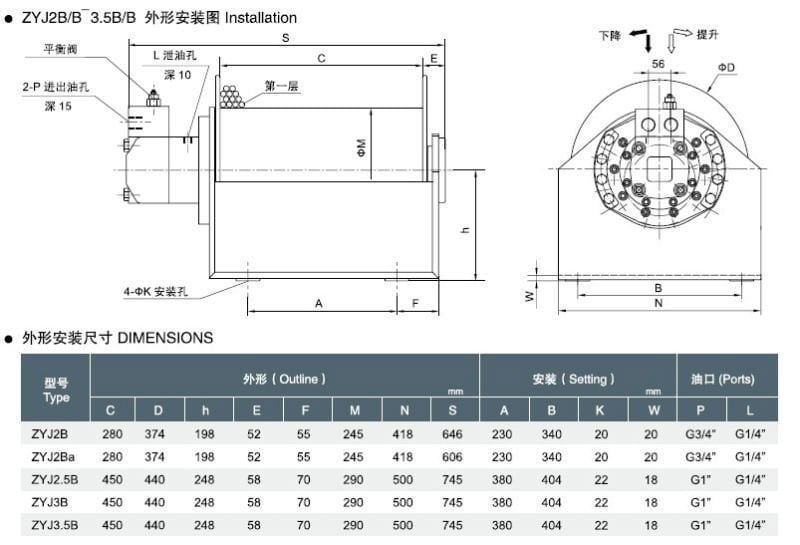

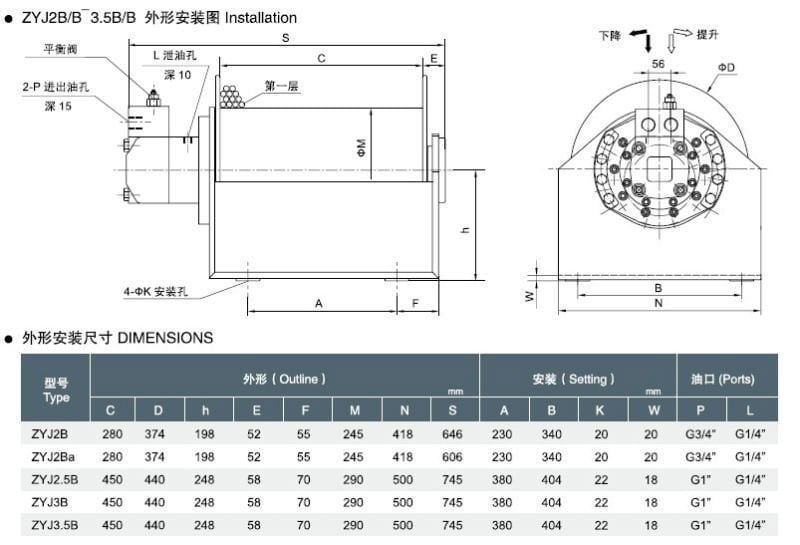

TECHNICAL DATA

| Type | (Max Pull)*10N | Working Pressure(Mpa) | Rope Layers (n°) | Suggesied Rope Diameter(mm) | Rope Capacity(m) | Displacement(mr/r) | Max Rope Speed(m/min) | Associated motor | Weight(kg) | ||

| Firstn° | Lastn° | Firstn° | Lastn° | ||||||||

| ZYJ2B | 2300 | 1850 | 13.9 | 4 | 12 | 80 | 1890 | 34 | 40 | BM4-320 | 130 |

| ZYJ2Ba | 2300 | 1850 | 13.9 | 4 | 12 | 80 | 1890 | 34 | 40 | BM4-320 | 125 |

| ZYJ2.5B | 2500 | 1990 | 13 | 4 | 13 | 120 | 2400 | 30 | 36 | BM5-400 | 209 |

| ZYJ3B | 3000 | 2400 | 13 | 4 | 13 | 120 | 3000 | 26 | 32 | BM5-500 | 210 |

| ZYJ3.5B | 3500 | 2800 | 13 | 4 | 13 | 120 | 3750 | 22 | 28 | BM5-630 | 211 |

More Products