Product Description

SC Transmission

ZSY-ZDY-ZFY-ZLY-industrial-gearbox

Product Parameters

|

Applicable Industries |

Manufacturing Plant, Food & Beverage Factory, Farms, Retail, Construction works , Energy & Mining, Advertising Company |

|

Gearing Arrangement |

Helical |

|

Output Torque |

4~17000 |

|

Input Speed |

750~3500rpm |

|

Output Speed |

0.06~310 |

|

Place of Origin |

China |

|

Brand Name |

HUAKE |

|

Product name |

Gearbox |

|

Application |

Machine Tool |

|

Color |

Blue |

|

Ratio |

5-100 |

|

Mounting Position |

Horizontal (foot Mounted) |

|

Material |

Steel |

|

Certificate |

ISO9001 |

|

Warranty |

1 Year |

|

Heat treatment |

Quenching |

|

Keyword |

Gearbox |

Product Description

Characteristics

1.The gear is made of high strength low carbon alloy steel through carburization and quenching. The hardness of tooth surface may

reach to HRC58-62. All gear adapts NC tooth grinding process, high in accuracy and good in contactperformance;

2.High in transmission efficiency: single stage, more than 96.5%; double-stage, more than 93%; three-stage, more than 90%;

3.Smooth and stable in run, low noise;

4.Compact, light, long life, high bearing capacity;

5.Easy to disassemble, inspect and assemble.

Detailed Photos

Components:

1. Housing: Cast Iron or Steel Plate Welding

2. Gear Set: Hardened Helical Gear Pairs, Carburizing, Quenching, Grinding, Gear Hardness HRC54-62

3. Input Configurations:

Single or Double Keyed CZPT Shaft Input

4. Output Configurations:

Single or Double Keyed CZPT Shaft Output

5. Main Options: Backstop

Forced Lubrication Oil Pump

Cooling Fan, Cooling Coils

Features:

1. Optional welding steel plate gear box

2. High quality alloy steel helical gears, carburizing, quenching, grinding, large load capacity

3. Optimized design, interchangeable spare parts

4. High efficiency, high reliability, long service life, low noise

5. Output shaft rotation direction: clockwise, counterclockwise or bidirectional

6. A variety of shaft configurations: single or double input and output shaft in 1 side or 2 sides

7. Optional backstop and lengthening output shafts

Packaging & Shipping

Company Profile

| Application: | Motor, Electric Cars, Motorcycle, Machinery, Marine, Toy, Agricultural Machinery, Car, Power Transmission |

|---|---|

| Function: | Distribution Power, Clutch, Change Drive Torque, Change Drive Direction, Speed Changing, Speed Reduction, Speed Increase |

| Layout: | Cycloidal |

| Type: | Planetary Gear Box |

| Certificate: | CCC CE |

| Logo: | Support Custom |

| Samples: |

US$ 100/Piece

1 Piece(Min.Order) | |

|---|

How to Calculate Transmission Ratio for a Cycloidal Gearbox

Using a cycloidal gearbox can be very useful in a wide variety of situations. However, it’s important to understand how to use it properly before implementing it. This article discusses the benefits of using a cycloidal gearbox, how to calculate the transmission ratio, and how to determine the effects of dynamic and inertial forces on the gearbox.

Dynamic and inertial effects

Various studies have been done to study the dynamic and inertial effects of cycloidal gearboxes. These studies have been performed using numerical, analytical and experimental methods. Depending on the nature of the load and its distribution along the gear, a variety of models have been developed. These models use finite element method to determine accurate contact stresses. Some of these models have been developed to address the nonlinear elasticity of contacts.

Inertial imbalance in a cycloidal gearbox causes vibration and can affect the efficiency of the device. This can increase mechanical losses and increase wear and tear. The efficiency of the device also depends on the torque applied to the cycloidal disk. The effectiveness of the device increases as the load increases. Similarly, the nonlinear contact dynamics are also associated with an increase in efficiency.

A new model of a cycloidal reducer has been developed to predict the effects of several operational conditions. The model is based on rigid body dynamics and uses a non-linear stiffness coefficient. The model has been validated through numerical and analytical methods. The model offers drastic reduction in computational costs. The model allows for a quick analysis of several operational conditions.

The main contribution of the paper is the investigation of the load distribution on the cycloidal disc. The study of this aspect is important because it allows for an analysis of the rotating parts and stresses. It also provides an indication of which gear profiles are best suited for optimizing torque transmission. The study has been conducted with a variety of cycloidal gearboxes and is useful in determining the performance of different types of cycloidal gearboxes.

To study the load distribution on the cycloidal disc, the authors investigated the relationship between contact force, cycloidal gearboxes and different gear profiles. They found that the non-linear contact dynamics have a large impact on the efficiency of a cycloidal gearbox. The cycloidal gearbox is an ideal solution for applications that involve highly dynamic servos. It can also be used in machine tool applications and food processing industries.

The study found that there are three common design principles of cycloidal reducers. These are the contact force distribution, the speed reduction and the trochoidal profile of the cycloidal disc. The trochoidal profile has to be defined carefully to ensure correct mating of the rotating parts. The trochoidal profile provides an indication of which gear profiles are best for optimizing torque transmission. The contact force distribution can be improved by refining the mesh along the disc’s width.

As the input speed increases, the efficiency of the reducer increases. This is because contact forces are constantly changing in magnitude and orientation. A cycloidal reducer with a one tooth difference can reduce input speed by up to 87:1 in a single stage. It also has the ability to handle high-cycle moves without backlash.

Transmission ratio calculation

Getting the correct transmission ratio calculation for a cycloidal gearbox requires a good understanding of what a gearbox is, as well as the product that it is being used for. The correct ratio is calculated by dividing the output speed of the output gear by the input speed of the input gear. This is usually accomplished by using a stopwatch. In some cases, a catalog or product specification may be required. The correct ratio is determined by a combination of factors, such as the amount of torque applied to the mechanism, as well as the size of the gears involved.

A cycloidal gear is a type of gear tooth profile that can be represented using a spline. It is also possible to model a gear with a cycloidal profile by using a spline to connect points against the beginning of a coordinate system. This is important in the design and functionality of a gear.

There are many different gears used in machines and devices. These include the herringbone gear, the helical gear and the spiral bevel gear. The best transmission ratios are typically obtained with a cycloidal gearbox. In addition to ensuring the accuracy of positioning, a cycloidal gearbox provides excellent backlash. Cycloid gears have a high degree of mechanical efficiency, low friction, and minimal moment of inertia.

A cycloidal gearbox is often referred to as a planetary gearbox, though it is technically a single-stage gearbox. In addition to having a ring gear, the gearbox has an eccentric bearing that drives the cycloidal disc in an eccentric rotation. This makes the cycloidal gearbox a good choice for high gear ratios in compact designs.

The cycloid disc is the key element of a cycloidal gearbox. The cycloid disc has n=9 lobes, and each lobe of the disc moves by a lobe for every revolution of the drive shaft. The cycloid disc is then geared to a stationary ring gear. The cycloidal disc’s lobes act like teeth on the stationary ring gear.

There are many different gears that are classified by the profile of the gear teeth. The most common gears are the involute and helical gears. Most motion control gears include spur designs. However, there are many other types of gears that are used in various applications. The cycloidal gear is one of the more complicated gears to design. The cycloid disc’s outline can be represented using markers or smooth lines, though a scatter chart will also do.

The cycloid disc’s lobes rotate on a reference pitch circle of pins. These pins rotate 40 deg during the eccentric rotation of the drive shaft. The pins rotate around the disc to achieve a steady rotation of the output shaft.

The cycloid disc’s other obvious, and possibly more important, feature is the’magic’ number of pins. This is the number of pins that protrude through the face of the disc. The disc has holes that are larger than the pins. This allows the pins to protrude through the disc and attach to the output shaft.

Application

Whether you’re building a robot drive or you’re simply looking for a gearbox to reduce the speed of your vehicle, a cycloidal gearbox is a great way to achieve a high reduction ratio. Cycloidal gearboxes are a low-friction, lightweight design that has an extremely stable transmission. They are suitable for industrial robots and can be used in many applications, including positioning robots.

Cycloidal gearboxes reduce speed by using eccentric motion. The eccentric motion enables the entire internal gear to rotate in wobbly cycloidal motion, which is then translated back into circular rotation. This eliminates the need for stacking gear stages. Cycloidal gearboxes also have less friction, higher strength, and greater durability than conventional gearboxes.

The cycloidal gearbox is also used in a number of applications, including marine propulsion systems, and robot drives. Cycloidal gearboxes reduce vibration by using offset gearing to cancel out vibrations.

Cycloidal gears have lower friction, higher strength, and better torsional stiffness than involute gears. They also have a reduced Hertzian contact stress, making them better than involute gears for use with shock loads. They also have a smaller size and weight than conventional gearboxes, and they have a higher reduction ratio than involute gears.

Cycloidal gears are typically used to reduce the speed of motors, but they also offer a number of other advantages. Cycloidal gearboxes have a smaller footprint than other gearboxes, allowing them to fit into confined spaces. They also have low backlash, allowing for precise movement. Cycloidal gears have a higher efficiency, resulting in lower power requirements and lower wear.

The cycloidal disc is one of the most important components of the gearbox. Cycloidal discs are normally designed with a short cycloid, which minimizes the eccentricity of the disc. They are also designed with a shortened flank, resulting in better strength and less stress concentration. Cycloidal discs are typically geared to a stationary ring gear. The cycloid is designed to roll around the stationary ring pins, which push against the circular holes in the disc. Cycloidal gearboxes typically employ two degrees of shift.

Cycloidal drives are ideal for heavy load applications. They also have high torsional stiffness, which makes them highly resistant to shock loads. Cycloidal drives also offer a high reduction ratio, which can be achieved without the need for a large input shaft. They are also compact and have a high service life.

The output shaft of a cycloidal gearbox always has two degrees of shifting, which ensures that the input and output shafts always rotate at a different speed. The output shaft would be a pin casing around the drive disks, which would also allow for easy maintenance.

Cycloidal gearboxes are also very compact and lightweight, so they are ideal for use in industrial robots. The cycloidal gearbox reducer is the most stable, low-vibration reducer in industrial robots, and it has a wide transmission ratio range.

editor by CX 2023-11-10

China High Torque Zy Series Parallel Shaft Cylindrical Gear Speed Reducer Gearbox small cycloidal gearbox

Item Description

Solution Description

Higher Torque Zy Sequence Parallel shaft Cylindrical Equipment Velocity Reducer gearbox

Factors:

one. Housing: Forged Iron or Metal Plate Welding

two. Gear Set: Hardened Helical Equipment Pairs, Carburizing, Quenching, Grinding, Gear Hardness HRC54-sixty two

3. Input Configurations:

Solitary or Double Keyed Solid Shaft Enter

4. Output Configurations:

Single or Double Keyed Reliable Shaft Output

five. Major Possibilities:

Backstop

Pressured Lubrication Oil Pump

Cooling Admirer, Cooling Coils

In depth Photographs

Designs:

ZDY Series, ZLY Sequence, ZSY Collection, ZFY Collection

Attributes:

one. Optional welding metal plate equipment box

two. High quality alloy steel helical gears, carburizing, quenching, grinding, big load capability

three. Optimized style, interchangeable spare parts

4. Higher efficiency, substantial trustworthiness, long support life, low sound

5. Output shaft rotation direction: clockwise, counterclockwise or bidirectional

six. A variety of shaft configurations: solitary or double input and output shaft in 1 aspect or 2 sides

7. Optional backstop and lengthening output shafts

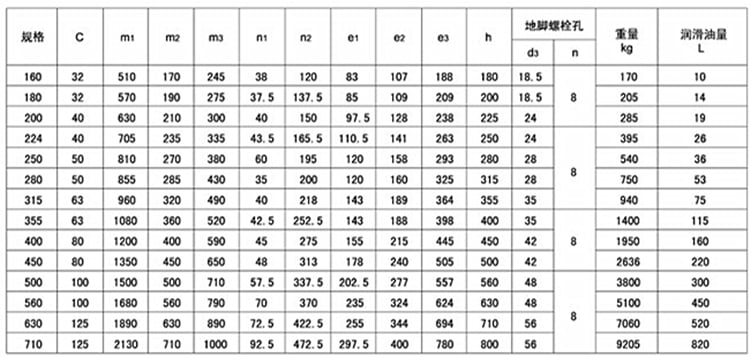

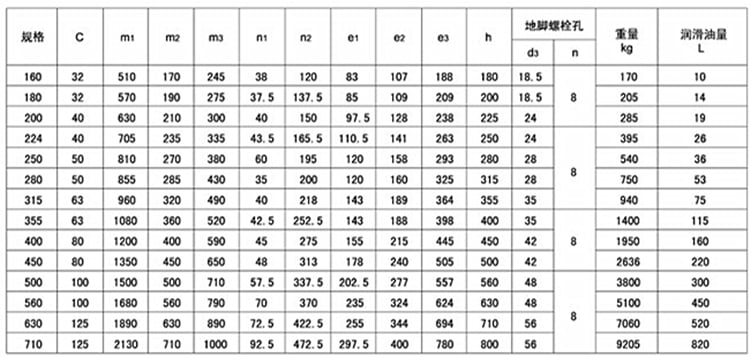

Item Parameters

Parameters:

| ZY Collection | Models | Ratio |

| ZDY (1 Phase) | ZDY80, ZDY100, ZDY125, ZDY160, ZDY200, ZDY250, ZDY280, ZDY315, ZDY355, ZDY400, ZDY450, ZDY500, ZDY560 | 1.twenty five~6.three |

| ZLY (2 Phase) | ZLY112, ZLY125, ZLY140, ZLY160, ZLY180, ZLY200, ZLY224, ZLY250, ZLY280, ZLY315, ZLY355, ZLY400, ZLY450, ZLY500, ZLY560, ZLY630, ZLY710 | six.3~twenty |

| ZSY (3 Phase) | ZSY160, ZSY180, ZSY200, ZSY224, ZSY250, ZSY280, ZSY315, ZSY355, ZSY400, ZSY450, ZSY500, ZSY560, ZSY630, ZSY710 | 22.4~a hundred |

| ZFY (4 Phase) | ZFY180, ZFY200, ZFY225, ZFY250, ZFY280, ZFY320, ZFY360, ZFY400, ZFY450, ZFY500, ZFY560, ZFY630, ZFY710 | one hundred~five hundred |

Installation:

Horizontal Mounted

Vertical Mounted

Lubrication:

Oil Dip and Splash Lubrication

Forced Lubrication

Cooling:

Natural Cooling

Auxiliary Cooling Products (Cooling Admirer, Cooling Coils)

Packaging & Delivery

Company Profile

Our Positive aspects

After Revenue Services

| Pre-sale solutions | 1. Pick tools model. |

| 2.Design and style and manufacture merchandise according to clients’ specific need. | |

| three.Prepare complex private for consumers | |

| Services during offering | one.Pre-examine and take items forward of supply. |

| two. Assist customers to draft solving strategies. | |

| After-sale providers | 1.Help clients to get ready for the very first development plan. |

| two. Prepare the first-line operators. | |

| three.Consider initiative to get rid of the difficulties quickly. | |

| four. Offer technological exchanging. |

FAQ

FAQ:

one.Q:What varieties of gearbox can you make for us?

A:Major products of our business: UDL sequence velocity variator,RV sequence worm gear reducer, ATA sequence shaft mounted gearbox, X,B sequence gear reducer,

P collection planetary gearbox and R, S, K, and F series helical-tooth reducer, a lot more

than 1 hundred designs and hundreds of specifications

2.Q:Can you make as per custom made drawing?

A: Indeed, we provide personalized support for clients.

three.Q:What is your phrases of payment ?

A: 30% Advance payment by T/T following signing the agreement.70% prior to shipping

4.Q:What is your MOQ?

A: 1 Set

Welcome to make contact with us for more depth information and inquiry.

If you have certain parameters and need for our gearbox, customization is available.

|

US $100-10,000 / Piece | |

1 Piece (Min. Order) |

###

| Application: | Machinery |

|---|---|

| Function: | Change Drive Torque, Speed Changing, Speed Reduction |

| Layout: | Cycloidal |

| Hardness: | Hardened Tooth Surface |

| Installation: | Vertical Type |

| Step: | Three-Step |

###

| Customization: |

Available

|

|---|

###

| ZY Series | Models | Ratio |

| ZDY (1 Stage) | ZDY80, ZDY100, ZDY125, ZDY160, ZDY200, ZDY250, ZDY280, ZDY315, ZDY355, ZDY400, ZDY450, ZDY500, ZDY560 | 1.25~6.3 |

| ZLY (2 Stage) | ZLY112, ZLY125, ZLY140, ZLY160, ZLY180, ZLY200, ZLY224, ZLY250, ZLY280, ZLY315, ZLY355, ZLY400, ZLY450, ZLY500, ZLY560, ZLY630, ZLY710 | 6.3~20 |

| ZSY (3 Stage) | ZSY160, ZSY180, ZSY200, ZSY224, ZSY250, ZSY280, ZSY315, ZSY355, ZSY400, ZSY450, ZSY500, ZSY560, ZSY630, ZSY710 | 22.4~100 |

| ZFY (4 Stage) | ZFY180, ZFY200, ZFY225, ZFY250, ZFY280, ZFY320, ZFY360, ZFY400, ZFY450, ZFY500, ZFY560, ZFY630, ZFY710 | 100~500 |

###

| Pre-sale services | 1. Select equipment model. |

| 2.Design and manufacture products according to clients’ special requirement. | |

| 3.Train technical personal for clients | |

| Services during selling | 1.Pre-check and accept products ahead of delivery. |

| 2. Help clients to draft solving plans. | |

| After-sale services | 1.Assist clients to prepare for the first construction scheme. |

| 2. Train the first-line operators. | |

| 3.Take initiative to eliminate the trouble rapidly. | |

| 4. Provide technical exchanging. |

|

US $100-10,000 / Piece | |

1 Piece (Min. Order) |

###

| Application: | Machinery |

|---|---|

| Function: | Change Drive Torque, Speed Changing, Speed Reduction |

| Layout: | Cycloidal |

| Hardness: | Hardened Tooth Surface |

| Installation: | Vertical Type |

| Step: | Three-Step |

###

| Customization: |

Available

|

|---|

###

| ZY Series | Models | Ratio |

| ZDY (1 Stage) | ZDY80, ZDY100, ZDY125, ZDY160, ZDY200, ZDY250, ZDY280, ZDY315, ZDY355, ZDY400, ZDY450, ZDY500, ZDY560 | 1.25~6.3 |

| ZLY (2 Stage) | ZLY112, ZLY125, ZLY140, ZLY160, ZLY180, ZLY200, ZLY224, ZLY250, ZLY280, ZLY315, ZLY355, ZLY400, ZLY450, ZLY500, ZLY560, ZLY630, ZLY710 | 6.3~20 |

| ZSY (3 Stage) | ZSY160, ZSY180, ZSY200, ZSY224, ZSY250, ZSY280, ZSY315, ZSY355, ZSY400, ZSY450, ZSY500, ZSY560, ZSY630, ZSY710 | 22.4~100 |

| ZFY (4 Stage) | ZFY180, ZFY200, ZFY225, ZFY250, ZFY280, ZFY320, ZFY360, ZFY400, ZFY450, ZFY500, ZFY560, ZFY630, ZFY710 | 100~500 |

###

| Pre-sale services | 1. Select equipment model. |

| 2.Design and manufacture products according to clients’ special requirement. | |

| 3.Train technical personal for clients | |

| Services during selling | 1.Pre-check and accept products ahead of delivery. |

| 2. Help clients to draft solving plans. | |

| After-sale services | 1.Assist clients to prepare for the first construction scheme. |

| 2. Train the first-line operators. | |

| 3.Take initiative to eliminate the trouble rapidly. | |

| 4. Provide technical exchanging. |

The Advantages of Using a Cyclone Gearbox

Using a cycloidal gearbox to drive an input shaft is a very effective way to reduce the speed of a machine. It does this by reducing the speed of the input shaft by a predetermined ratio. It is capable of very high ratios in relatively small sizes.

Transmission ratio

Whether you’re building a marine propulsion system or a pump for the oil and gas industry, there are certain advantages to using cycloidal gearboxes. Compared to other gearbox types, they’re shorter and have better torque density. These gearboxes also offer the best weight and positioning accuracy.

The basic design of a cycloidal gearbox is similar to that of a planetary gearbox. The main difference is in the profile of the gear teeth.

Cycloid gears have less tooth flank wear and lower Hertzian contact stress. They also have lower friction and torsional stiffness. These advantages make them ideal for applications that involve heavy loads or high-speed drives. They’re also good for high gear ratios.

In a cycloidal gearbox, the input shaft drives an eccentric bearing, while the output shaft drives the cycloidal disc. The cycloidal disc rotates around a fixed ring, and the pins of the ring gear engage the holes in the disc. The pins then drive the output shaft as the disc rotates.

Cycloid gears are ideal for applications that require high gear ratios and low friction. They’re also good for applications that require high torsional stiffness and shock load resistance. They’re also suitable for applications that require a compact design and low backlash.

The transmission ratio of a cycloidal gearbox is determined by the number of lobes on the cycloidal disc. The n=n design of the cycloidal disc moves one lobe per revolution of the input shaft.

Cycloid gears can be manufactured to reduce the gear ratio from 30:1 to 300:1. These gears are suitable for high-end applications, especially in the automation industry. They also offer the best positioning accuracy and backlash. However, they require special manufacturing processes and require non-standard characteristics.

Compressive force

Compared with conventional gearboxes, the cycloidal gearbox has a unique set of kinematics. It has an eccentric bearing in a rotating frame, which drives the cycloidal disc. It is characterized by low backlash and torsional stiffness, which enables geared motion.

In this study, the effects of design parameters were investigated to develop the optimal design of a cycloidal reducer. Three main rolling nodes were studied: a cycloidal disc, an outer race and the input shaft. These were used to analyze the motion related dynamic forces, which can be used to calculate stresses and strains. The gear mesh frequency was calculated using a formula, which incorporated a correction factor for the rotating frame of the outer race.

A three-dimensional finite element analysis (FEA) study was conducted to evaluate the cycloidal disc. The effects of the size of the holes on the disc’s induced stresses were investigated. The study also looked at the torque ripple of a cycloidal drive.

The authors of this study also explored backlash distribution in the output mechanism, which took into account the machining deviations and structure and geometry of the output mechanism. The study also looked at the relative efficiency of a cycloidal reducer, which was based on a single disc cycloidal reducer with a one-tooth difference.

The authors of this study were able to deduce the contact stress of the cycloidal disc, which is calculated using the material-based contact stiffness. This can be used to determine accurate contact stresses in a cycloidal gearbox.

It is important to know the ratios needed for calculation of the bearing rate. This can be calculated using the formula f = k (S x R) where S is the volume of the element, R is the mass, k is the contact stiffness and f is the force vector.

Rotational direction

Unlike the conventional ring gear which has a single axis of rotation, cycloidal gearbox has three rotational axes which are parallel and are located in a single plane. A cycloidal gearbox has excellent torsional stiffness and shock load capacity. It also ensures constant angular velocity, and is used in high-speed gearbox applications.

A cycloidal gearbox consists of an input shaft, a drive member and a cycloidal disc. The disc rotates in one direction, while the input shaft rotates in the opposite direction. The input shaft eccentrically mounts to the drive member. The cycloidal disc meshes with the ring-gear housing, and the rotational motion of the cycloidal disc is transferred to the output shaft.

To calculate the rotational direction of a cycloidal gearbox, the cycloid must have the correct angular orientation and the centerline of the cycloid should be aligned with the center of the output hole. The cycloid’s shortest length should be equal to the radius of the pin circle. The cycloid’s largest radius should be the size of the bearing’s exterior diameter.

A single-stage gear will not have much space to work with, so you’ll need a multistage gear to maximize space. This is also the reason that cycloid gears are usually designed with a shortened cycloid.

To calculate the most efficient tooth profile for a cycloidal gear, a new method was devised. This method uses a mathematical model that uses the cycloid’s rotational direction and a few other geometric parameters. Using a piecewise function related to the distribution of pressure angle, the cycloid’s most efficient profile is determined. It is then superimposed on the theoretical profile. The new method is much more flexible than the conventional method, and can adapt to changing trends of the cycloidal profile.

Design

Several designs of cycloidal gearboxes have been developed. These gearboxes have a large reduction ratio in one stage. They are mainly used for heavy machines. They provide good torsional stiffness and shock load capacity. However, they also have vibrations at high RPM. Several studies have been conducted to find a solution to this problem.

A cycloidal gearbox is designed by calculating the reduction ratio of a mechanism. This ratio is obtained by the size of the input speed. This is then multiplied by the reduction ratio of the gear profile.

The most important factor in the design of a cycloidal gearbox is the load distribution along the width of the gear. Using this as a design criterion, the amplitude of vibration can be reduced. This will ensure that the gearbox is working properly. In order to generate proper mating conditions, the trochoidal profile on the cycloidal disc periphery must be defined accurately.

One of the most common forms of cycloidal gears is circular arc toothing. This is the most common type of toothing used today.

Another form of gear is the hypocycloid. This form requires the rolling circle diameter to be equal to half the base circle diameter. Another special case is the point tooth form. This form is also called clock toothing.

In order to make this gear profile work, the initial point of contact must remain fixed to the edge of the rolling disk. This will generate the hypocycloid curve. The curve is traced from this initial point.

To investigate this gear profile, the authors used a 3D finite element analysis. They used the mathematical model of gear manufacturing that included kinematics parameters, output moment calculations, and machining steps. The resulting design eliminated backlash.

Sizing and selection

Choosing a gearbox can be a complex task. There are many factors that need to be taken into account. You need to determine the type of application, the required speed, the load, and the ratio of the gearbox. By gaining this information, you can find a solution that works best for you.

The first thing you need to do is find the proper size. There are several sizing programs available to help you determine the best gearbox for your application. You can start by drawing a cycloidal gear to help you create the part.

During sizing, it is important to consider the environment. Shock loads, environmental conditions, and ambient temperatures can increase wear on the gear teeth. The temperature also has a significant impact on lubrication viscosities and seal materials.

You also need to consider the input and output speed. This is because the input speed will change your gearbox ratio calculations. If you exceed the input speed, you can damage the seals and cause premature wear on the shaft bearings.

Another important aspect of sizing is the service factor. This factor determines the amount of torque the gearbox can handle. The service factor can be as low as 1.4, which is sufficient for most industrial applications. However, high shock loads and impact loads will require higher service factors. Failure to account for these factors can lead to broken shafts and damaged bearings.

The output style is also important. You need to determine if you want a keyless or keyed hollow bore, as well as if you need an output flange. If you choose a keyless hollow bore, you will need to select a seal material that can withstand the higher temperatures.

editor by czh 2023-01-05

China Crane lifting and mining Transmission Gearbox Parallel Shaft Helical Gearbox Reducer sequential gearbox

Warranty: 1 years, 1 Year de velocidades de transmissao grau 90

Applicable Industries: Garment Shops, Building Material Shops, Machinery Repair Shops, Farms, Retail, Construction works

Weight (KG): 40 KG

Customized support: OEM, ODM

Gearing Arrangement: Spur or Helical or Cycloidal

Output Torque: top to 36000N.m

Input Speed: 600-1500r/min de velocidades de transmissao

Output Speed: 0.011-161r/min

Product name: Crane lifting and mining Transmission Gearbox

Heat treatment: Quenching/Carburising/Gear Grinding

Material: Steel or cast iron

Mounting Position: Foot/ Flange Mounted

Gear material: Low carbon high alloy steel

Color: Red, blue, green, gray, white

Quality control system: ISO9001:2008

Keyword: Transmission Gerbox

Ratio: 8-50

Packaging Details: Wooden box and carton or wooden pallet gear speed reducer/gear box reducer/cycloidal gear reducer/caixa de velocidades de transmissao grau 90

Port: HangZhou port,ZheJiang port,HangZhou port or HangZhou

Professional mechanical transmission field–ZheJiang Ruige Transmission Machinery Co., LtdSpecializing in the production of gears, gearboxes, Horizontal Gearbox, Helical Gearbox,automobile rear axles and lifting accessories Products Description ZQ Series Helical GearboxZQCylindrical Horizontal Gearbox, two-stage cylindrical gear transmission. It is widely used in lifting and transportationmachinery, mining machinery and general chemical industry. Its working temperature is – 40C +45C, input speed is not higher than1500 rpm, gear drive circumferential speed is not more than 14 m/s, and it can run in both directions.The field of cylindrical Horizontal Gearbox is widely used in metallurgical equipment, mining equipment, automation equipment, food machinery, packaging equipment, tobacco equipment etc..

| Assembly Form(Horizontal Gearbox) | ||

| ZQ Horizontal Gearbox has 9 assembly forms. The input shaft is conical, the output shaft end has cylindrical shaft extension (Z type),gear type (CA type), and European (cross slider) coupling (F type). | ||

| ZQSeries Cylindrical Helical Gearbox Shape, Shaft End and Installation Dimensions | ||||||||

| Quality Upgrade: Manufacture with the latest technical standards and upgrade productsSturdy and durable:Made of high quality material, durableGood applicability of the whole machine:It can be installed in many ways with input and output modes.High reliability:heavy weight, stable operation and long service lifeRunning low noise:In the process of operation, the noise is low, giving you a better experience and use. | Manufacture with the latest technical standards and upgrade products | |

| Sturdy and durable | Made of high quality material, durable | |

| Good applicability of the whole machine | It can be installed in many ways with input and output modes. | |

| High reliability | Heavy weight, stable operation and long service life | |

| Running low noise | In the process of operation, the noise is low, giving you a better experience and use. | |

| Thickening gearThe gears of gear box reducer are upgraded in an all-round way, the running efficiency of the thicker gears is higher and faster, the gearsare durable, and the service life of the reducer is prolonged. | ||

| Q:what can you buy from us? | ||||||||

| A:Axle,Gearbox,Transmission,Horizontal Gearbox,other crane parts(electric hoist, electric trolley, lifting hook etc) | ||||||||

| Q: What should I provide when I choose gearbox/Horizontal Gearbox? | ||||||||

| A: The best way is to provide the motor drawing with parameter. Our engineer will check and recommend the most suitable gear speed reducer model for your refer. Or you can also provide below specification as well:1) Type, model and torque.2) Ratio or output speed3) Working condition and connection method4) Quality and installed machine name5) Input mode and input speed6) Motor brand model or flange and motor shaft size | ||||||||

| Q:What are the differetiates between RUIGE with other supplier? | ||||||||

| A:Profeession and reliability. Our advantages are multiple available technologies, strong quality assurance, and good at project & supply chain management. | ||||||||

| Q:Is there a cost for RUIGE service about Horizontal Gearbox? | ||||||||

| A:There is no additional cost above the product and tooling price except third party service. | ||||||||

| Q:Will I be CZPT to visit the supplier myself? | ||||||||

| A:First, all of our supply partner has undergone a series of screening and audit process, we can provide complete audit report to you.Secondly, if you want to perform your own independent supplier audit procedure, our representitives can accompany and assit with you to achieve it. | ||||||||

| Q:How to deal with the quality problem? | ||||||||

| A:a. With our partners we perform APQP at an early stage in each project.b. Our factory must fully understand the quality concerns from customers and implement product & process quality requirements.c. Our quality professionals who perform patrol inspection in our factories.We perform final inspection before the goods are packed.d. We have 3rd party inspectors who perform final audit checks on the packed goods prior to dispatch from China. | ||||||||

| Q:Can you take responsibility for me? | ||||||||

| A:Of course, I’m happy to help you! But I just take responsibility for my products.Please offer a test report, if it was our fault, absolutely we can make a compensation for you, my friend! | ||||||||

| Q:Do you like to serve the client only with small orders? | ||||||||

| A:We enjoy to grow up together with all our clients whatever big or small.You will become bigger and bigger to be with us. | ||||||||

How to Select a Gearbox

When you drive your vehicle, the gearbox provides you with traction and speed. The lower gear provides the most traction, while the higher gear has the most speed. Selecting the right gear for your driving conditions will help you maximize both. The right gearing will vary based on road conditions, load, and speed. Short gearing will accelerate you more quickly, while tall gearing will increase top speed. However, you should understand how to use the gearbox before driving.

Function

The function of the gearbox is to transmit rotational energy to the machine’s drive train. The ratio between input and output torque is the ratio of the torque to the speed of rotation. Gearboxes have many different functions. A gearbox may have multiple functions or one function that is used to drive several other machines. If one gear is not turning, the other will be able to turn the gearbox. This is where the gearbox gets its name.

The pitch-controlled system has an equal number of failure modes as the electrical system, accounting for a large proportion of the longest machine downtime and halt time. The relationship between mechanisms and faults is not easily modeled mathematically. Failure modes of gearboxes are shown in Fig. 3. A gearbox’s true service life is six to eight years. However, a gearbox’s fault detection process must be developed as mature technology is required to reduce the downtime and avoid catastrophic incidents.

A gearbox is a vital piece of machinery. It processes energy produced by an engine to move the machine’s parts. A gearbox’s efficiency depends on how efficiently it transfers energy. The higher the ratio, the more torque is transferred to the wheels. It is a common component of bicycles, cars, and a variety of other devices. Its four major functions include:

In addition to ensuring gearbox reliability, a gearbox’s maintainability should be evaluated in the design phase. Maintainability considerations should be integrated into the gearbox design, such as the type of spare parts available. An appropriate maintenance regime will also determine how often to replace or repair specific parts. A proper maintenance procedure will also ensure that the gearbox is accessible. Whether it is easy to access or difficult to reach, accessibility is essential.

Purpose

A car’s transmission connects the engine to the wheels, allowing a higher-speed crankshaft to provide leverage. High-torque engines are necessary for the vehicle’s starting, acceleration, and meeting road resistance. The gearbox reduces the engine’s speed and provides torque variations at the wheels. The transmission also provides reversing power, making it possible to move the vehicle backwards and forwards.

Gears transmit power from one shaft to another. The size of the gears and number of teeth determine the amount of torque the unit can transmit. A higher gear ratio means more torque, but slower speed. The gearbox’s lever moves the engaging part on the shaft. The lever also slides the gears and synchronizers into place. If the lever slips to the left or right, the engine operates in second gear.

Gearboxes need to be closely monitored to reduce the likelihood of premature failure. Various tests are available to detect defective gear teeth and increase machine reliability. Figure 1.11(a) and (b) show a gearbox with 18 teeth and a 1.5:1 transmission ratio. The input shaft is connected to a sheave and drives a “V” belt. This transmission ratio allows the gearbox to reduce the speed of the motor, while increasing torque and reducing output speed.

When it comes to speed reduction, gear box is the most common method for reducing motor torque. The torque output is directly proportional to the volume of the motor. A small gearbox, for example, can produce as much torque as a large motor with the same output speed. The same holds true for the reverse. There are hybrid drives and in-line gearboxes. Regardless of the type, knowing about the functions of a gearbox will make it easier to choose the right one for your specific application.

Application

When selecting a gearbox, the service factor must be considered. Service factor is the difference between the actual capacity of the gearbox and the value required by the application. Additional requirements for the gearbox may result in premature seal wear or overheating. The service factor should be as low as possible, as it could be the difference between the lifetime of the gearbox and its failure. In some cases, a gearbox’s service factor can be as high as 1.4, which is sufficient for most industrial applications.

China dominates the renewable energy industry, with the largest installed capacity of 1000 gigawatts and more than 2000 terawatt hours of electricity generated each year. The growth in these sectors is expected to increase the demand for gearboxes. For example, in China, wind and hydropower energy production are the major components of wind and solar power plants. The increased installation capacity indicates increased use of gearboxes for these industries. A gearbox that is not suitable for its application will not be functional, which may be detrimental to the production of products in the country.

A gearbox can be mounted in one of four different positions. The first three positions are concentric, parallel, or right angle, and the fourth position is shaft mount. A shaft mount gearbox is typically used in applications where the motor can’t be mounted via a foot. These positions are discussed in more detail below. Choosing the correct gearbox is essential in your business, but remember that a well-designed gearbox will help your bottom line.

The service factor of a gearbox is dependent on the type of load. A high shock load, for example, can cause premature failure of the gear teeth or shaft bearings. In such cases, a higher service factor is required. In other cases, a gearbox that is designed for high shock loads can withstand such loads without deteriorating its performance. Moreover, it will also reduce the cost of maintaining the gearbox over time.

Material

When choosing the material for your gearbox, you must balance the strength, durability, and cost of the design. This article will discuss the different types of materials and their respective applications and power transmission calculations. A variety of alloys are available, each of which offers its own advantages, including improved hardness and wear resistance. The following are some of the common alloys used in gears. The advantage of alloys is their competitive pricing. A gear made from one of these materials is usually stronger than its counterparts.

The carbon content of SPCC prevents the material from hardening like SS. However, thin sheets made from SPCC are often used for gears with lower strength. Because of the low carbon content, SPCC’s surface doesn’t harden as quickly as SS gears do, so soft nitriding is needed to provide hardness. However, if you want a gear that won’t rust, then you should consider SS or FCD.

In addition to cars, gearboxes are also used in the aerospace industry. They are used in space travel and are used in airplane engines. In agriculture, they are used in irrigation, pest and insect control machinery, and plowing machines. They are also used in construction equipment like cranes, bulldozers, and tractors. Gearboxes are also used in the food processing industry, including conveyor systems, kilns, and packaging machinery.

The teeth of the gears in your gearbox are important when it comes to performance. A properly meshing gear will allow the gears to achieve peak performance and withstand torque. Gear teeth are like tiny levers, and effective meshing reduces stress and slippage. A stationary parametric analysis will help you determine the quality of meshing throughout the gearing cycle. This method is often the most accurate way to determine whether your gears are meshing well.

Manufacturing

The global gear market is divided into five key regions, namely, North America, Europe, Asia Pacific, and Latin America. Among these regions, Asia Pacific is expected to generate the largest GDP, owing to rapidly growing energy demand and investments in industrial infrastructure. This region is also home to some of the largest manufacturing bases, and its continuous building of new buildings and homes will support the industry’s growth. In terms of application, gearboxes are used in construction, agricultural machinery, and transportation.

The Industrial Gearbox market is anticipated to expand during the next several years, driven by the rapid growth of the construction industry and business advancements. However, there are several challenges that hamper the growth of the industry. These include the high cost of operations and maintenance of gear units. This report covers the market size of industrial gearboxes globally, as well as their manufacturing technologies. It also includes manufacturer data for the period of 2020-2024. The report also features a discussion of market drivers and restraints.

Global health crisis and decreasing seaborne commerce have moderately adverse effects on the industry. Falling seaborne commerce has created a barrier to investment. The value of international crude oil is expected to cross USD 0 by April 2020, putting an end to new assets development and exploitation. In such a scenario, the global gearbox market will face many challenges. However, the opportunities are huge. So, the market for industrial gearboxes is expected to grow by more than 6% by 2020, thanks to the increasing number of light vehicles sold in the country.

The main shaft of a gearbox, also known as the output shaft, spins at different speeds and transfers torque to an automobile. The output shaft is splined so that a coupler and gear can be connected to it. The counter shaft and primary shaft are supported by bearings, which reduce friction in the spinning element. Another important part of a gearbox is the gears, which vary in tooth count. The number of teeth determines how much torque a gear can transfer. In addition, the gears can glide in any position.

editor by czh

Best China manufacturer & factory china supplier ZDY series parallel shaft helical speed reducer reduction gearbox for kneader machine With high quality best price

We offer OEM service.

Overview

Quick Details

- Applicable Industries:

-

Manufacturing Plant

- Model Number:

-

zfy zsy zdy zly 250 315 355 750

- Rated Power:

-

EPG specializing in the manufacture of rotocultivator ploughshares and other non-standardized farm machinery cutting tools.

1.5~6229KW (customized)

- Pole:

-

Single Two Three Stage Speed Reducer

- Ratio:

-

1.25-100

- Housing Material:

-

Cast Iron

- Working temperature:

-

-40~45℃

- Application:

-

About EPG Group Divisions Formed in 1966, Shen represents an impressive list of internationally respected companies and manufactures under licence to a number of these companies. We also manufacture a rThe PTO shaft is the mechanical device that transfer the power from the tractor to the agricultural implement. The PTO shaft is made of two joints connected by telescopic tubes: one joint connects the outer tube of the PTO shaft with the tractor power take-off , the other joint connects the inner tube of the PTO shaft with the implement. The range of the EPG GROUP PTO shafts includes 9 sizes of different dimensions according to the power to be transferred . The sizes of the EPG GROUP PTO shafts and the power that can be transferred at 540 rpm are : SIZE 1 up to 16HP SIZE 2 up to 21HP SIZE 3 up to 30 HP SIZE 4 up to 35HP SIZE 5 up to 47HP SIZE 6 up to 60HP SIZE 7 up to 70HP SIZE 8 up to 90HP SIZE10 up to 110HPange of products and equipment developed and designed by our own engineers. In 1990 an employee owner group was formed and acquired 50% of the company from co-founder Mike Shen . These shareholders span a diverse section of the company and underwrite the efficient function of the EPG Group.

fan of coling tower mining, chemical industry,steel ,lifting

- Process:

-

Carburizing, Nitriding , Grinding

- Efficiency:

-

94%~98%

- Mounting Position:

-

Horizontal,Vertical,Flange

Supply Ability

- Supply Ability:

- 300 Set/Sets per Month parallel shaft helical speed reducer reduction gearbox kneader

Packaging & Delivery

- Packaging Details

- sea worthy wooden case for ZDY series parallel shaft helical speed reducer reduction gearbox for kneader machine

- Port

- Qingdao

Online Customization

Product Description

PROFESSIONAL MANUFACTURE

—— SINCE 1995

Z Series Helical Gear Reducer

Z (ZDY, ZLY, ZSY, and ZFY) serieshard tooth surface cylindrical gear reducer

D (DBY and DCY) series hard tooth surface cone gear reducer

Chinese speed reducer is widely used in mining machinery, chemical industry,steel metallurgy, light industry,environmental protection, paper making, printing, lifting transport, food industry and so on.

Main Series Product: R series helical gear reducer, K series spiral bevel gear reducer, NGW, P series planetary reducer, H B series gearbox, Z (ZDY, ZLY, ZSY, and ZFY) serial hard tooth surface cylindrical gear reducer, D (DBY and DCY) serial hard tooth surface cone gear reducer, cycloid reducer, etc. Meanwhile, map sample processing business can be undertaken.

Feature:

-

Applicable to the metallurgical,power generation,water treatment,construction,chemical,paper,

textiles,medicine,food and other industries.

-

The transmission efficiency of single-stage can reach up to 98%, two-stage can reach 96%, three-stage can reach 94%.

-

The gear processed by Carburizing & Grinding with high precision.

-

High precision gear, steady transmission, large load capacity

-

Long service life.

- One Two Three Stage Speed Reducer

Specification

zfy zsy zdy zly 3 stage servo motor reduction gear box reducer Gearbox for Rubber Kneader Machine:

(please contact us for more types & model)

| Driven machines | |||

| Waste water treatment | Thickeners,filter presses,flocculation apparata,aerators,raking equipment,combined longitudinal and rotary rakes,pre-thickeners,screw pumps,water turbines,centrifugal pumps | Dredgers | Bucket conveyors, dumping devices, carterpillar travelling gears, bucket wheel excavators as pick up, bucket wheel excavator for primitive material, cutter head, traversing gears |

| Chemical industry | Plate bending machines, extruders, dough mills, rubbers calenders, cooling drums, mixers for uniform media, agitators for media with uniform density, toasters, centrifuges | Metal working mills | plate tilters, ingot pushers, winding machines, cooling bed transfer frames, roller straigheners, table continuous intermittent, roller tables reversing tube mills, shears continuous, casting drivers, reversing blooming mills |

| Metal working mills | Reversing slabbing mills. reversing wire mills, reversing sheet mills, reversing plate mill, roll adjustment drives | Conveyors | Bucket conveyors, hauling winches, hoists, belt conveyors, good lifts, passenger lifts, apron conveyors, escalators, rail travlling gears |

| Frequency converters | Reciprocating compressors | ||

| Cranes | Slewing gears, luffing gears, travelling gears, hoisting gear, derricking jib cranes | Cooling towers | Cooling tower fans, blowers axial and radial |

| Cane sugar production | Cane knives, cane mills | Beet sugar production | Beet cossettes macerators, extraction plants, mechanical refrigerators, juice boilers, sugar beet washing machines, sugar beet cutter |

| Paper machines | Pulper drives | Cableways | Material ropeways, continuous ropeway |

| Cement industry | Concrete mixer, breaker, rotary kilns, tube mills, separators, roll crushers | ||

Model selection:

Closely using the ideal reduction ratio.

Reduction ratio = servo motor speed / reducer output shaft speed

Torque calculation: Torque calculation is very important for the life of reducer, and pay attention to whether the maximum torque value (TP) of acceleration exceeds the maximum load torque of the reducer.

The applicable power is usually the applicable power of the servo models on the market, the applicability of the reducer is very high, the working coefficient can be maintained above 1.2, but the choice can also be based on their own needs to decide .ZSY series two stage cylindrical transmission reducer for belt conveyor. ZLY series 2 stage helical speed reducer for paper mill.1 10 ratio gearbox speed reducer for plastic extruder machine. ZLY Rubber Extruder Mini Electric Motor Gear Speed Reducer. ZLY 2 stage helical cylindrical transmission gearbox for conveyor. ZSY ZFY type Sand mining gearbox Cylindrical bevel gear box for fan of coling tower China Z D type helical gear reducer gearbox for limestone desulfurization machine 3 stage servo motor reduction gear box reducer Gearbox for Rubber Kneader Machine ZDY series parallel shaft helical speed reducer reduction gearbox for kneader machine.

Technology

Chinese Electric Motor Gear Speed Reducer is a mechanical transmission in many fields of the national economy. The product categories covered by the industry include all kinds of gear reducer, planetary gear reducer and worm gearbox, as well as various special transmission devices such as speed increasing device, speed control Devices, including various types of flexible transmission devices, such as compound transmission. Products and services in the field of metallurgy, nonferrous metals, coal, building materials, ships, water conservancy, electricity, construction machinery and petrochemical industries.

In all fields of national economy and national defense industry, gearbox products have a wide range of applications. Food light industry, electric machinery, construction machinery, metallurgy machinery, cement machinery, environmental protection machinery, electronic appliances, road construction machinery, water conservancy machinery, chemical machinery, mining machinery, conveyor machinery, building materials machinery, rubber machinery, petroleum machinery and other industries have strong demand of Reducer products.ZSY series two stage cylindrical transmission reducer for belt conveyor.ZLY series 2 stage helical speed reducer for paper mill.1 10 ratio gearbox speed reducer for plastic extruder machine.ZLY Rubber Extruder Mini Electric Motor Gear Speed Reducer.ZLY 2 stage helical cylindrical transmission gearbox for conveyor. ZSY ZFY type Sand mining gearbox Cylindrical bevel gear box for fan of coling tower China Z D type helical gear reducer gearbox for limestone desulfurization machine 3 stage servo motor reduction gear box reducer Gearbox for Rubber Kneader Machine ZDY series parallel shaft helical speed reducer reduction gearbox for kneader machine.

Packaging & Shipping

Company Information

Founded in 1995, HangZhou Ever-Power Power machinery Co.,Ltd has 22 years of reducer production experience and credibility. The company has professional engineer team, advanced technology production and skilled workers, with located in HangZhou of ZheJiang province which has solid industrial base and developed transportation.

FAQ

1.Q:Are you the factory or trading company?

A:We are the professional Factory with 22 years of experience.

2.Q:Can you customize according to our requirements?

A:Yes, we can design nonstandard products according to customer’s drawing and sample.

3.Q:How long is the delivery date?

A:10-20 working days.

4.Q:Where is your factory?

A:We are in HangZhou of ZheJiang Province, you can get here by high speed train or fly to Jinan.

Welcome to visit us!

Best China manufacturer & factory Wholesale price F47 FA47 FAF47 FF47 hollow shaft helical gear reducer parallel axis gearbox With high quality best price

Due to our sincerity in offering best service to our clients, understanding of your needs and overriding sense of responsibility toward filling ordering requirements,a specialized supplier of a full range of chains, sprockets, gears, gear racks, V-belts, couplings and reducers, pto shaft, agricultural gearboxes….

Overview

Quick Details

- Applicable Industries:

-

Manufacturing Plant

- Brand Name:

-

OEM

- ITEM NO:

-

SYF

- Mounting Position:

-

Foot Mounted. Flange Mounted

- Ratio:

-

1.3-58800

- Bearing:

-

NSK Bearing

- Warranty:

-

1-2 Years

- Certificate:

-

ISO9001

- Input speed:

-

0-3000rpm/min

- Output speed:

-

0.1-356rpm/min

- Output torque:

-

0-18000N.m

- Motor power:

-

0.18-11kw

Packaging & Delivery

-

Lead Time

: -

Quantity(Pieces) 1 – 1 2 – 5 6 – 10 >10 Est. Time(days) 5 10 15 To be negotiated

Online Customization

Product Description

F SERIES PARALLEL SHAFT HELICAL GEAR REDUCER

F series parallel shaft helical gear reducer has the characteristics of small volume, light weight, large transfer torque, low energy consumption, high efficiency, low temperature rise, strong load force and various structure forms. Suitable for different installation conditions.

It can be combined with R series, K series, S series, etc. to obtain lower speed and greater torque.

F SERIES STRUCTURE DRAWING

|

OUTPUT SPEED: |

0.1~356 r/min |

|

OUTPUT TORQUE: |

≤18000 N.m |

|

POWER: |

0.18~11kw |

|

MOUNTING TYPE: |

Foot-mounted Foot-mounted and Hollow- mounted Hollow-shaft B5 Flange-mounted B5 Flange-mounted and Hollow- mounted B14Flange-mounted and Hollow- mounted |

PRECISION BEVEL GEAR

20CrMn Ti material – low carbon alloy steel

Imported gear grinding machine processing, high hardness, stable performance.

Vacuum furnace carburizing heat treatment, carburizing layer uniform.

HIGH QUALITY SHELL MATERIAL

The box body is made of HT200 material,which is cleaned by professional screening and washing equipment to ensure that the inner cavity of the box body is cleaner without iron filings.

HIGH QUALITY OUTPUT SHAFT

New standard axle, multi-precision machining, through rigorous dynamic and static balance test, to ensure low noise and smooth operation of reducer

PROFESSIONAL AIR TIGHTNRSS TEST

Before spraying each reducer, air tightness test is needed to minimize the occurrence of oil leakage and air leakage. Ensure the long life and good operation of the reducer.

F SERIES HELICAL GEAR UNITS OVERVIEW:

●Parallel output,structMost commonly, it is a splined drive shaft installed on a tractor or truck allowing implements with mating fittings to be powered directly by the engine.ure compact,carrying bigger torque,operation stable,voice low,lifetime long.

●Mounting mode :foot-mounted,flange-mounted,torque arm-mounted.

●Ratio:ratio of 2-stage is 8.1-191,ratio of 3-stage is 28.2-273,ratio of combination is up to 18509.

●For 2-stage basic type geared,rotation direction of input shaft is the same that of output shaft;for 3-stage basic type geared,their directions are reverse;for combination,please contact Ever Power.

●Output mode:hollow shaft output or solid shaft output.

●Average efficiency: 2-stage 96%, 3-stage 94%,combination 85%.

F SERIES PARALLEL SHAFT HELICAL GEAR REDUCER MOUNTING DIMENSIONS OUTPUT SHAFT DIMENSIONS

F foot shaft mounting parallel helical gear reducer

FA hollow shaft mounting parallel shaft helical gear reducer

FF flange shaft mounting parallel shaft helical gear reducer

Our Company

HANGZHOU EVER-POWER GROUP, ONE OF THE BIGGEST GEARBOX FACTORY IN CHINA, ELECTROMECHANICAL EQUIPMENT SUPPLY STATION

Our company is located in the city of HangZhou, ZheJiang Province of China.

We handle the products of power transmission, our lines mainly cover series products in speed reducers, gearboxes , associated electricial motors and other power transmissionMain products include: manure spreading truck, potato planting/harvesting machine, disc plough, disc harrow, grass Mower/slasher, corn and wheat thershers, seeder, mouldboard plow, deep subsoiler machines, rotary tiller, rear blade, fertilizer spreader, combine rice harvester, corn thresher, farm trailer, ridger, trencher, stubble cleaner, earth auger, cultivator and its accessories: Plow disc blades, harrowing film, plough tip and share, cultivator tine, casting parts etc. accessories. Based on the versatile functions, our products can be utilized in many fields: machines of waste water treatment, dredgers, chemical industry, cranes, metal working mills, conveyors, paper industry, cement industry, cableways and so on.With the excellent quality and reasonable price , our products enjoy a good reputation from customers and the peers all over the world.

Furthermore, the R&D investment are annually increasing for the purpose of better meeting the new demands of our cusAside from gear ratio, the most important factor that determines efficiency is the contact pattern between worm and mating gears. Manufacturing the reducer housing, and worm and gear subassemblies creates a stack up of tolerances, so the position of the gear-tooth centerline cannot be accurately predicted. Therefore, assemblers must manually measure and adjust the contact pattern by varying the position of shims behind the front and rear bearings on the output gear shaft. This is timeconsuming and costly, so most manufacturers use statistical analysis to predict shim quantity and location. This provides a reasonably centered contact pattern most of the time.tomers and adapting the new tendency of the industry.

Depending on the principles of honestly operating and mutual benefit, We sincerely look forward to cooperating with you.

Application area

Certifications

Packing&Transportion

PACKING AND TRANSPORTION

●Packaging: In order to ensure the integrity of product appearance, we will choose cartons, wooden pallets and wooden pallets according to customer needs.

●Delivery time: Each reducer is manufactured and tested in accordance with strict and fixed procedures to ensure that the quality is correct before leaving the factory and delivery on time.

●Transportation mode: We will choose the most suitable mode of transportation for our customers according to the weight and size of the goods. We can also choose the mode of transportation according to the needs of our customers.

●Receiving and after-sales service: After receiving the goods, please check whether they are in good condition. We will provide customers with perfect after-sales service.

FAQ

Q1: Are you a trading company or a manufacturer ?

A: We are a manufacturer in ZheJiang Province, China. Our company owns the ability of manufacturing, processing,designing and R&D. We welcome your visit.

Q2: How we select models and specifications?

A: According to the specific details of the demands from the part of enquiry, we will recommend the products’ models upon synthesizing the factors of field of products usage, power, torque arm and ratio…

Q3: How is your price? Can you offer any discount?

A: Our prices are always competitive. If the customer can place a large order, we surely will allow discount.

Q4: How long should I wait for the feedback after I send the enquiry?

A4: We will reply the enquiries without any delay, 12 hours at most.

Q5: What is your product warranty period?

A: We have the certifications of ISO99001,CE, SGS.

Q6: What industries are your gearboxes being used?

A: Our gearboxes are widely applied to metallurgical equipment, mining equipment, automation equipment, food machinery, packaging equipment, tobacco equipment and so on.

Hot-sale Product